Abstract

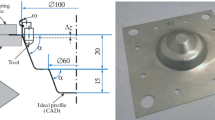

The panel production of small batch sizes for the hull of large ships requires a stable and flexible forming process, which is momentarily manually controlled by a system operator. The manual forming press control includes the metal sheet handling above the forming tool for defining the contact point and engagement depth of the sword and subjective monitoring of the forming degree by using the light gap check method. For objectifying the process monitoring and reducing the dependency on the experience of the system operator an automated solution is needed. Within the automated process control the metal sheet deformation behavior has to be predicted in real-time during the forming process. To achieve this, the deformation prognosis for the ship panel’s production is handled inside the described work. Based on a state of art analysis a geometrical approach to describe the metal sheet deformation behavior is developed for the multi-step forming process by three-point-bending. The related geometrical parameters are predicted using a new type of prediction method by means of an artificial neural network. This prediction method requires the network definition and extensive experimental investigations for training the artificial neural network.

Similar content being viewed by others

References

Handreg T, Froitzheim P, Fuchs N, Flügge W, Stoltmann M, Woernle C (2019) Concept of an automated Framework for sheet metal cold forming. In: Schüppstuhl T, Tracht K, Rossmann J (eds) Tagungsband des 4. Kongresses Montage Handhabung Industrieroboter, Heidelberg: Springer Vieweg, Berlin, pp 117–127 in Springer Fachmedien Wiesbaden GmbH. ISBN 978-3-662-59317-2

Stoltmann M, Froitzheim P, Fuchs N, Woernle C (2018) Feedforward control of a crane manipulator. In: IMSD TL (ed) The 5th joint international conference on multibody system dynamics. Lisboa, Portugal

Stoltmann, M., P. Froitzheim, N. Fuchs C. Woernle. Flatness-based feedforward control of a crane manipulator with four load chains. In: B. Corves, P. Wenger M. Hüsing, EuCoMeS 2018. Proceedings of the 7th European Conference on Mechanism Science. Cham: Springer, 2019, S. 61–68. ISBN 3319980203

Reissner J, Müller-Duysing M, Dannenmann E, Ladwig J (1990) Biegen. In: Lange K (ed) Umformtechnik. Handbuch für Industrie und Wissenschaft. Zweite, völlig neubearbeitete und erweiterte Auflage. Springer Berlin Heidelberg, Berlin, pp 243–310. Imprint; Springer. ISBN 978-3-662-10687-7

Zhang Z (2014) A refined model of thee-roller Elastoplastix Assymmetrical pre-bending of plate. J Iron Steel Res Int 21(3):328–334

Fu Z, Mo J, Zhang W (2009) Study on multiple-step incremental air-bending forming of sheet metal with springback model and FEM simulation [online]. Int J Adv Manuf Technol 45(5-6):448–458. Verfügbar unter. https://doi.org/10.1007/s00170-009-1982-2. ISSN 0268-3768

Müller-Duysing M (1993) Die Berechnung und adaptive Steuerung des Drei-Punkt-Biegens. VDI-Verlag, Düsseldorf

SHIN JG, Kim Y-G, Jong-Ho N (2004) An integrated approach to determine optimal process information of large-scale line-heating process with deformation simulation. Journal of Ship Production 20(4):211–220

Shin JG, Ryu CH, Lee JH, Kim WD (2003) User-friendly, advanced line heating automation for accurate plate forming. Journal of Ship Production 19(1):8–15

Noh J, Shin JG, Ko K, Chung JA (2009) An embedded prototype for a distributed and automated line heating system. Journal of Ship Production 25(4):182–190

Woernle C (2011) Mehrkörpersysteme. In: Eine Einführung in die Kinematik und Dynamik von Systemen starrer Körper. Springer, Heidelberg

Fuchs N, Froitzheim P, Flügge W, Woernle C (2018) Characterization of the metal sheet forming by free bending with LS-DYNA. In: GMBH D (ed) LS-DYNA forum. DYNAmore GmbH, Stuttgart, pp 124–125. ISBN 978-3-9816215-5-6

Thoms V, KALICH J (2002) Prozeßvorhersage beim Stanznieten mit neuronalen Netzen. Ergebnisse eines Vorhabens der industriellen Gemeinschaftsforschung (IGF). EFB-Forschungsbericht. Nr. 179. Hannover, EFB

Viswanathan V, Kinsey B, Cao J (2003) Experimental implementation of neural network springback control for sheet metal forming [online]. J Eng Mater Technol 125(2):141. https://doi.org/10.1115/1.1555652. ISSN 00944289. Verfügbar unter

Forcellese A, Gabrielli F, Ruffini R (1998) Effect of the training set size on springback control by neural network in an air bending process [online]. J Mater Process Technol 80–81:493–500. https://doi.org/10.1016/S0924-0136(98)00122-8. Journal of Materials Processing Technology. Verfügbar unter

Backhaus K (2015) Fortgeschrittene multivariante Analysemethoden. Eine anwendungsorientierte Einführung, Gabler

Grosan C, Abraham A (2011) Intelligent systems. A modern approach. Intelligent systems reference library, vol 17. Springer, New York

Raabe D (2004) Einfluß der Rauheit metallischer Oberflächen auf Reibung und Rückfederung. Düsseldorf, März

Wolfstieg U, Macherauch E (1973) Ursachen und Bewertung von Eigenspannungen [online]. Chemie Ingenieur Technik - CIT 45(11):760–770. https://doi.org/10.1002/cite.330451103. ISSN 0009-286X. Verfügbar unter

Acknowledgements

This research and development project was supported by the European Regional Development Fund (EFRE). Support was also provided by the lead partner Technologie-Beratungsinstitut (TBI) according to the directive for support, development and innovation of the Ministry of Economics, Construction and Tourism of Mecklenburg-Vorpommern.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Froitzheim, P., Stoltmann, M., Fuchs, N. et al. Prediction of metal sheet forming based on a geometrical model approach. Int J Mater Form 13, 829–839 (2020). https://doi.org/10.1007/s12289-019-01529-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-019-01529-9