Abstract

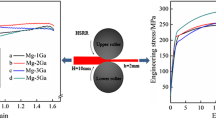

Microstructure, texture characteristics, mechanical and bio-corrosion properties of the Mg–5Zn–xSr alloys (x = 0, 0.2, 0.6, 1.0) prepared by high strain rate rolling are carefully studied. A low level of Sr addition enhances dynamic precipitation of nano-scale MgZn2 particles in the as-rolled Mg–5Zn alloy, with 0.6%Sr showing the maximum efficiency. These high-density MgZn2 particles can pin grain boundaries of dynamic recrystallization grains and inhibit their growth. A low level of Sr addition (≤ 0.6%) enhances the (0002) basal texture, but 1.0%Sr is just the reverse. The as-rolled Mg–5Zn–0.6Sr alloy exhibits the best combination of ultimate tensile strength (359 MPa) and elongation to rupture (20%). The high strength can be attributable to a reduced grain size, precipitation and basal texture strengthening. The Mg–5Zn–xSr alloys exhibit excellent bio-corrosion resistance, but a minor Sr addition cannot bring about further bio-corrosion resistance improvement due to the multiple actions of grain size, DRX degree, dynamic precipitates and texture characteristics. The 0.6%Sr addition can greatly improve the strength of the as-rolled alloy at no expense of bio-corrosion resistance.

Graphic Abstract

Similar content being viewed by others

References

M.P. Staiger, A.M. Pietak, J. Huadmai, G. Dias, Biomaterials 27, 1728–1734 (2006)

M.H. Yoo, Metall. Trans. A 12, 409–418 (1981)

M. Alvarez-Lopez, D. Pereda Maria, J.A. del Valle, M. Fernandez-Lorenzo, M.C. Garcia-Alonso, O.A. Ruano, M.L. Escudero, Acta Biomater. 6, 1763–1771 (2010)

P. Cao, M. Qian, D.H. StJohn, Scr. Mater. 53, 841–844 (2005)

J.H. Gao, S.K. Guan, Z.W. Ren, Mater. Lett. 65, 691–693 (2011)

C. Op’t Hoog, N. Birbilis, Y. Estrin, Adv. Eng. Mater. 10, 579–582 (2008)

G.R. Argade, S.K. Panigrahi, R.S. Mishra, Corros. Sci. 58, 145–151 (2012)

H.Y. Choi, W.J. Kim, J. Mech. Behav. Biomed. 51, 291–301 (2015)

J.B. Clark, Acta Metall. 13, 1281–1289 (1965)

L.Y. Wei, G.L. Dunlop, H. Westengen, Metall. Mater. Trans. A 26, 1705–1716 (1995)

B. Langelier, A. Korinek, P. Donnadieu, S. Esmaeili, Mater. Charact. 120, 18–29 (2016)

J.M. Rosalie, H. Somekawa, A. Singh, T. Mukai, J. Alloys Compd. 550, 114–123 (2013)

C.X. Xu, X. Wang, J.S. Zhang, Z.G. Zhang, Rare Met. Mater. Eng. 43, 1809–1814 (2014)

Y. Tian, H. Huang, G.Y. Yuan, C.L. Chen, Z.C. Wang, W.J. Ding, Mater. Lett. 130, 236–239 (2014)

B. Langelier, G. Sha, A. Korinek, P. Donnadieu, S.P. Ringer, S. Esmaeili, Mater. Des. 119, 290–296 (2017)

S.Q. Zhu, H.G. Yan, J.H. Chen, Y.Z. Wu, J.Z. Liu, J. Tian, Scr. Mater. 63, 985–988 (2010)

S.Q. Zhu, H.G. Yan, J.H. Chen, Y.Z. Wu, B. Su, Y.G. Du, X.Z. Liao, Scr. Mater. 67, 404–407 (2012)

Z.Y. Zou, J.H. Chen, H.G. Yan, B. Su, X.L. Gong, J. Mater. Eng. Perform. 25, 1974–1985 (2016)

J.H. Chen, G.Q. Chen, H.G. Yan, B. Su, X.L. Gong, B. Zhou, J. Mater. Eng. Perform. 26, 4748–4759 (2017)

M.X. Cheng, J.H. Chen, H.G. Yan, B. Su, Z.H. Yu, X.L. Gong, J. Alloys Compd. 691, 95–102 (2017)

H.Y. Lai, J.Y. Li, J.X. Li, Y. Zhang, Y.Z. Xu, J. Mater. Sci. Mater. Med. 29, 87–101 (2018)

Q.M. Tian, C.X. Zhang, M. Deo, L. Rivera-Castaneda, N. Masoudipour, R.G. Guan, H.N. Liu, Mater. Sci. Eng. C 96, 248–262 (2019)

K. Ohishi, C.L. Mendis, T. Homma, S. Kamado, T. Ohkubo, K. Hono, Acta Mater. 57, 5593–5604 (2009)

Harpreet.S. Brar, Joey. Wong, Michele.V. Manuel, J. Mech. Behav. Biomed. 7, 87–95 (2012)

J.D. Embury, R.B. Nicholson, Acta Metall. 13, 403–417 (1965)

C. Wang, Influence Rules and Action Mechanisms of Alloying Elements on the Stack Fault Energy and Twin Segregation Energy of Magnesium Alloy, PhD Thesis (Jilin University, 2015)

A. Rollett, F.J. Humphreys, G.S. Rohrer, Recrystallization and Related Annealing Phenomena (Elsevier, Germany, 2004), pp. 121–167

I. Basu, T. Al-Samman, Acta Mater. 67, 116–133 (2014)

K. Hantzsche, J. Bohlen, J. Wendt, K.U. Kainer, S.B. Yi, D. Letzig, Scr. Mater. 63, 725–730 (2010)

C. Chen, J.H. Chen, H.G. Yan, B. Su, M. Song, S.Q. Zhu, Mater. Des. 100, 58–66 (2016)

T. Homma, C.L. Mendis, K. Hono, S. Kamado, Mater. Sci. Eng. A 527, 2356–2362 (2010)

M. Masoumi, M. Pekguleryuz, Mater. Sci. Eng. A 529, 207–214 (2011)

J.D. Robson, D.T. Henry, B. Davis, Acta Mater. 57, 2739–2747 (2009)

Y.Z. Du, M.Y. Zheng, X.G. Qiao, D.B. Wang, W.Q. Peng, K. Wu, B.L. Jiang, Mater. Sci. Eng. A 656, 67–74 (2016)

A.A. Nayeb-Hashemi, J.B. Clark, ASM Metals Handbook—Alloy Phase Diagrams 7 (ASM International, 1986), pp. 149–156

J.F. Nie, Scr. Mater. 48, 1009–1015 (2003)

Y.Z. Du, X.G. Qiao, M.Y. Zheng, K. Wu, S.W. Xu, Mater. Des. 85, 549–557 (2015)

T. Al-Samman, Mater. Sci. Eng. A 560, 561–566 (2013)

H. Guo, J.H. Chen, H.G. Yan, W.J. Xia, B. Su, X.L. Gong, Z.L. Yu, Mater. Res. Express (2019). https://doi.org/10.1088/2053-1591/ab2398

Z. Shi, A. Atrens, Corros. Sci. 53, 226–246 (2011)

X.P. Zhang, Z.P. Zhao, F.M. Wu, Y.L. Wang, J. Wu, J. Mater. Sci. 42, 8523–8528 (2007)

B.S. Jie, Y.T. Tan, K.S. Fong, M.J. Tan, Procedia Eng. 207, 1475–1480 (2017)

C. Taltavull, Z. Shi, B. Torres, J. Rams, A. Atrens, J. Mater. Sci. Mater. Med. 25, 329–345 (2014)

Z. Pu, G.L. Song, S. Yang, J.C. Outeiro, O.W. Dillon Jr., D.A. Puleo, I.S. Jawahir, Corros. Sci. 57, 192–201 (2012)

R.L. Xin, Y.M. Luo, A.L. Zuo, J.C. Gao, Q. Liu, Mater. Lett. 72, 1–4 (2012)

Acknowledgements

This work is supported by National Natural Science Foundation of China (Grant No. 51571089).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yan, H., Gong, X., Chen, J. et al. Microstructure, Texture Characteristics, Mechanical and Bio-Corrosion Properties of High Strain Rate Rolled Mg–Zn–Sr Alloys. Met. Mater. Int. 27, 2249–2263 (2021). https://doi.org/10.1007/s12540-019-00601-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00601-y