Abstract

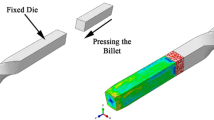

In the current study, aluminium 6063 alloy (AA6063) was successfully gain refined by twist extrusion (TE) technique. TE is a representative severe plastic deformation process to fabricate ultrafine-grained in bulk materials by repetitive passes. In order to investigate the influence of back pressure, a direct extrusion (DE) channel was embedded after the twist zone and the behavior of AA6063 was investigated and compared with and without this channel. Analyzing microstructural evolutions by scanning electron microscope and Vickers microhardness evaluations showed that, adding the DE channel increased the hardness distribution and a more homogenous structure was obtained. Finite element analysis was utilized to study the distribution of the equivalent plastic strain (PEEQ) numerically. According to the obtained results, with applying the TE process, strain increase was observed all over the sample surface, whereas modeling the DE channel after the twist zone caused a better homogeneity in the PEEQ distribution of the transverse cross-section. The PEEQ distribution during TE process can be correlated to the extent of grain refinement and the uniformity of ultrafine grains. This method seems to be very interesting and very promising for the future industrial application.

Graphic Abstract

Similar content being viewed by others

References

R.Z. Valiev, Developing SPD methods for processing bulk nanostructured materials with enhanced properties. Met. Mater. Int. 7(5), 413–420 (2001)

M.S. Kim, S.C. Kwon, S.T. Kim, S. Lee, H.T. Jeong, S.H. Choi, Effect of forging type on the deformation heterogeneities in multi-axial diagonal forged AA1100. Met. Mater. Int. 25(3), 779–793 (2019)

Y. Qi, R. Lapovok, Y. Estrin, Microstructure and electrical conductivity of aluminium/steel bimetallic rods processed by severe plastic deformation. J. Mater. Sci. 51(14), 6860–6875 (2016)

J.A. Munoz, O.F. Higuera, J.A. Benito, D. Bradai, T. Khelfa, R.E. Bolmaro, A.M. Jorge Jr., J.M. Cabrera, Analysis of the micro and substructural evolution during severe plastic deformation of ARMCO iron and consequences in mechanical properties. Mater. Sci. Eng. A 740–741, 108–120 (2019)

M. Sarkari-Khorrami, N. Saito, Y. Miyashita, M. Kondo, Texture variations and mechanical properties of aluminum during severe plastic deformation and friction stir processing with SiC nanoparticles. Mater. Sci. Eng. A 744, 349–364 (2019)

I. Balasundar, T. Raghu, On the die design for repetitive upsetting—extrusion (RUE) process. Int. J. Mater. Form. 6, 289–301 (2013)

J.M. Molina-Aldareguia, M.T. Perez-Prado, R.Z. Valiev, I.P. Semenova, I. Sabirov, High strength ultra-fine grained titanium produced via a novel SPD processing route. Int. J. Mater. Form. 3, 407–410 (2010)

R.B. Figueiredo, G.C.V. De Faria, P.R. Cetlin, T.G. Langdon, Three-dimensional analysis of plastic flow during high-pressure torsion. J. Mater. Sci. 48(13), 4524–4532 (2014)

B.P. Ho, H.Y. Um, J.G. Kim, H.Y. Jeong, S. Lee, H.S. Kim, Large deformation behavior of twin-induced plasticity steels under high-pressure torsion. Met. Mater. Int. 22(6), 1003–1008 (2016)

J. Vratna, M. Janecek, J. Cizek, D.J. Lee, E.Y. Yoon, H.S. Kim, Mechanical properties and microstructure evolution in ultrafine-grained AZ31 alloy processed by severe plastic deformation. J. Mater. Sci. 48(13), 4705–4712 (2013)

Y. Beygelzimer, A. Reshetov, S. Synkov, O. Prokofeva, R. Kulagin, Kinematics of metal flow during twist extrusion investigated with a new experimental method. J. Mater. Process. Technol. 209, 3650–3656 (2009)

Y. Beygelzimer, R. Kulagin, Y. Estrin, L.S. Toth, H.S. Kim, M.I. Latypov, Twist extrusion as a potent tool for obtaining advanced engineering materials: a review. Adv. Eng. Mater. 19(8), 1–24 (2017)

Y. Beygelzimer, R. Kulagin, M.I. Latypov, V. Varyukhin, H.S. Kim, Off-axis twist extrusion for uniform processing of round bars. Met. Mater. Int. 21(4), 734–740 (2015)

Y. Beygelzimer, V. Varyukhin, S. Synkov, Shear, vortices, and mixing during twist extrusion. Int. J. Mater. Form. 1, 443–446 (2008)

R. Kulagin, M.I. Latypov, H.S. Kim, V. Varyukhin, Y. Beygelzimer, Cross flow during twist extrusion: theory, experiment, and application. Metall. Mater. Trans. A 44a, 3211–3220 (2013)

A. Hasani, R. Lapovok, L.S. Tóth, A. Molinari, Deformation field variations in equal channel angular extrusion due to back pressure. Scr. Mater. 58, 771–774 (2008)

M.I. Latypov, I.V. Alexandrov, Y.E. Beygelzimer, S. Lee, H.S. Kim, Finite element analysis of plastic deformation in twist extrusion. Comput. Mater. Sci. 60, 194–200 (2012)

R. Kocich, A. Machackova, L. Kuncicka, Twist channel multi-angular pressing (TCMAP) as a new SPD process: numerical and experimental study. Mater. Sci. Eng. A 612, 445–455 (2014)

Y. Beygelzimer, D. Prilepo, R. Kulagin, V. Grishaev, O. Abramova, V. Varyukhin, M. Kulakov, Planar twist extrusion versus twist extrusion. J. Mater. Process. Technol. 211, 522–529 (2011)

S.A.A.A. Mousavi, A.R. Shahab, M. Mastoori, Computational study of Ti–6Al–4V flow behaviors during the twist extrusion process. Mater. Des. 29, 1316–1329 (2008)

F. Javadzadeh-Kalahroudi, A.R. Eivani, H.R. Jafarian, A. Amouri, R. Gholizadeh, Inhomogeneity in strain, microstructure and mechanical properties of AA1050 alloy during twist extrusion. Mater. Sci. Eng. A 667, 349–357 (2016)

S.V. Noor, A.R. Eivani, H.R. Jafarian, M. Mirzaei, Inhomogeneity in microstructure and mechanical properties during twist extrusion. Mater. Sci. Eng. A 652, 186–191 (2016)

Y. Yuan, A. Ma, X. Gou, J. Jiang, F. Lu, D. Song, Y. Zhu, Superior mechanical properties of ZK60 mg alloy processed by equal channel angular pressing and rolling. Mater. Sci. Eng. A 630, 45–50 (2015)

M.I.A.E. Aal, H.Y. Um, E.Y. Yoon, H.S. Kim, Microstructure evolution and mechanical properties of pure aluminum deformed by equal channel angular pressing and direct extrusion in one step through an integrated die. Mater. Sci. Eng. A 625, 252–263 (2015)

J.G. Kim, M. Latypov, N. Pardis, Y.E. Beygelzimer, H.S. Kim, Finite element analysis of the plastic deformation in tandem process of simple shear extrusion and twist extrusion. Mater. Des. 83, 858–865 (2015)

J.A. Munoz, M. Avalos, R.E. Bolmaro, Heterogeneity of strain path, texture and microstructure evolution of AA6063-T6 processed by equal channel angular sheet extrusion (ECASE). J. Alloys Compd. 768, 349–357 (2018)

S.K. Panigrahi, R. Jayaganthan, V. Pancholi, Effect of plastic deformation conditions on microstructural characteristics and mechanical properties of 6063 Al alloy. Mater. Des. 30, 1894–1901 (2009)

S.S. Lokesh-Vendra, S. Goel, N. Kumar, R. Jayaganthan, A study on fracture toughness and strain rate sensitivity of severely deformed Al 6063 alloys processed by multiaxial forging and rolling at cryogenic temperature. Mater. Sci. Eng. A 686, 82–92 (2017)

G. Faraji, S. Roostae, A.S. Nosrati, J.Y. Kang, H.S. Kim, Microstructure and mechanical properties of ultra-fine-grained Al–Mg–Si tubes produced by parallel tubular channel angular pressing process. Metall. Mater. Trans. A 46(4), 1805–1813 (2015)

S. Karabay, M. Zeren, M. Yilmaz, Investigation extrusion ratio effect on mechanical behaviour of extruded alloy AA-6063. J. Mater. Process. Technol. 135, 101–108 (2003)

Y. Wu, H. Liao, Corrosion Behavior of extruded near eutectic Al–Si–Mg and 6063 alloys. J. Mater. Sci. Technol. 29, 380–386 (2013)

I. Sabirov, M.T. Perez-Prado, M. Murashkin, J.M. Molina-Aldareguia, E.V. Bobruk, N.F. Yunusova, R.Z. Valiev, Application of equal channel angular pressing with parallel channels for grain for refinement in aluminium alloys and its effect on deformation behavior. Int. J. Mater. Form. 3, 411–414 (2010)

M. Khadyko, D. Morin, T. Borvik, O.S. Hopperstad, Tensile ductility of extruded aluminium alloy AA6063 in different tempers. Mater. Sci. Eng. A 744, 500–511 (2019)

L.R. Zeng, Z.M. Song, X.M. Wu, C.H. Li, G.P. Zhang, Room-temperature workability of 6063 alloy for fitting clamps of overhead conductor lines. Mater. Des. 65, 187–192 (2015)

M. Das, G. Das, M. Ghosh, M. Wegner, V. Rajnikant, S. Ghosh-chowdhury, T.K. Pal, Microstructures and mechanical properties of HPT processed 6063 Al alloy. Mater. Sci. Eng. A 558, 525–532 (2012)

M. Samaee, S. Najafi, A.R. Eivani, H.R. Jafarian, J. Zhou, Simultaneous improvements of the strength and ductility of fine-grained AA6063 alloy with increasing number of ECAP passes. Mater. Sci. Eng. A 669, 350–357 (2016)

SCh Yoon, A.V. Nagasekhar, H.S. Kim, Finite element analysis of the bending behavior of a workpiece in equal channel angular pressing. Met. Mater. Int. 15(2), 215–219 (2009)

H.H. Lee, W. Kim, KCh Jung, S. Seo, J.K. Lee, H.L. Park, K.T. Park, H.S. Kim, Circumferential twisting during route B equal-channel angular pressing. J. Mater. Process. Technol. 259, 305–311 (2018)

U.M. Iqbal, V.S. Senthil-Kumar, S. Gopalakannan, Application of response surface methodology in optimizing the process parameters of twist extrusion process for AA6061-T6 aluminum alloy. Measurement 94, 126–138 (2016)

A.V. Nagasekhar, H.S. Kim, Analysis of T-shaped equal channel angular pressing using the finite element method. Met. Mater. Int. 14(5), 565–568 (2008)

Yu Ivanisenko, R. Kulagin, V. Fedorov, A. Mazilkin, T. Scherer, B. Baretzky, H. Hahn, High pressure torsion extrusion as a new severe plastic deformation process. Mater. Sci. Eng. A 664, 247–256 (2016)

S.A.A.A. Mousavi, S.R. Bahadori, The effects of post annealing on the mechanical properties, microstructure and texture evolutions of pure copper deformed by twist extrusion process. Mater. Sci. Eng. A 528, 1242–1246 (2011)

D. Orlov, Y. Beygelzimer, S. Synkov, V. Varyukhin, N. Tsuji, Z. Horita, Plastic flow, structure and mechanical properties in pure Al deformed by twist extrusion. Mater. Sci. Eng. A 519, 105–111 (2009)

S.A.A.A. Mousavi, Sh Ranjbar-Bahadori, A.R. Shahab, Numerical and experimental studies of the plastic strains distribution using subsequent direct extrusion after three twist extrusion passes. Mater. Sci. Eng. A 527, 3967–3974 (2010)

Sh Ranjbar-Bahadori, S.A.A.A. Mousavi, Examination of an aluminum alloy behavior under different routes of twist extrusion processing. Mater. Sci. Eng. A 528, 6527–6534 (2011)

M. Nouri, H. Mohammadian-Semnani, E. Emadoddin, H.S. Kim, Investigation of direct extrusion channel effects on twist extrusion using experimental and finite element analysis. Measurement 127, 115–123 (2018)

S.R. Bahadori, K. Dehghani, S.A.A.A. Mousavi, Comparison of microstructure and mechanical properties of pure copper processed by twist extrusion and equal channel angular pressing. Mater. Lett. 152, 48–52 (2015)

M.S. Mohebbi, A. Akbarzadeh, Experimental study and FEM analysis of redundant strains in flow forming of tubes. J. Mater. Process. Technol. 210, 389–395 (2010)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nouri, M., Mohammadian Semnani, H. & Emadoddin, E. Computational and Experimental Studies on the Effect Back Pressure on Twist Extrusion Process. Met. Mater. Int. 27, 2910–2918 (2021). https://doi.org/10.1007/s12540-020-00668-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00668-y