Abstract

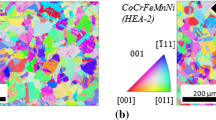

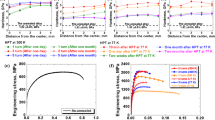

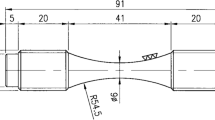

In this study, we examined the effect of deformation twins and dislocation cell structures on the fatigue properties of the CoCrFeMnNi high-entropy alloy using rotational bending fatigue tests. The dislocation cell structures and deformation twins were generated by prestraining the CoCrFeMnNi high-entropy alloy at room temperature (27 °C) and a cryogenic temperature (− 196 °C), respectively. To eliminate the effect of different material strengths on fatigue behavior, the tensile strengths of the specimens evaluated in the fatigue tests were kept similar by controlling the prestraining under room and cryogenic temperatures. The results of the rotational bending fatigue tests revealed that the CoCrFeMnNi high-entropy alloy prestrained at room temperature exhibited higher fatigue resistance and fatigue limit than the specimen prestrained at a cryogenic temperature. A small quantity of large micro-voids was formed at the triple junction of the grain boundaries in the specimen prestrained at room temperature, whereas a large quantity of small micro-voids was formed in the region where the deformation twins intersected the grain boundaries in the specimen prestrained at a cryogenic temperature. Therefore, it is concluded that the different aspects of micro-void formation affected the crack initiation and, consequently, the fatigue properties of the room and cryogenic temperature-prestrained alloys.

Graphic Abstract

Similar content being viewed by others

References

J.-W. Yeh, S.K. Chen, S.U.J. Lin, J.-Y. Gan, T.-S. Chin, T. Shun, C.H. Tsau, S.Y. Chang, Adv. Eng. Mater. 6, 299–303 (2004)

Y. Zhang, T.T. Zuo, Z. Tang, M.C. Gao, K.A. Dahmen, P.K. Liaw, Z.P. Lu, Prog. Mater. Sci. 61, 1–93 (2014)

M.-H. Tsai, J.-W. Yeh, Mater. Res. Lett. 2, 107–123 (2014)

J.-W. Yeh, JOM 65, 1759–1771 (2013)

Y.Y. Chen, T. Duval, U.D. Hung, J.W. Yeh, H.C. Shih, Corros. Sci. 47, 2257–2279 (2005)

B. Gludovatz, A. Hohenwarter, D. Catoor, E.H. Chang, E.P. George, R.O. Ritchie, Science 345, 1153 (2014)

J.I. Lee, H.S. Oh, J.H. Kim, E.S. Park, Korean J. Met. Mater. 55, 1–9 (2017)

S.I. Hong, J. Moon, S.K. Hong, H.S. Kim, Mater. Sci. Eng. A 682, 569–576 (2017)

B. Cantor, I.T.H. Chang, P. Knight, A.J.B. Vincent, Mater. Sci. Eng. A 375–377, 213–218 (2004)

J.Y. He, W.H. Liu, H. Wang, Y. Wu, X.J. Liu, T.G. Nieh, Z.P. Lu, Acta Mater. 62, 105–113 (2014)

N.D. Stepanov, N.Y. Yurchenko, M.A. Tikhonovsky, G.A. Salishchev, J. Alloys Compd. 687, 59–71 (2016)

N. Stepanov, D.G. Shaysultanov, N. Yurchenko, M. Klimova, S. Zherebtsov, G. Salishchev, Mater. Sci. Forum 879, 1853–1858 (2016)

S.H. Joo, H. Kato, M.J. Jang, J. Moon, E.B. Kim, S.J. Hong, H.S. Kim, J. Alloys Compd. 698, 591–604 (2017)

M. Gabriele Poletti, G. Fiore, F. Gili, D. Mangherini, L. Battezzati, Mater. Des. 115, 247–254 (2017)

K.R. Lim, K.S. Lee, J.S. Lee, J.Y. Kim, H.J. Chang, Y.S. Na, J. Alloys Compd. 728, 1235–1238 (2017)

A. Shafiei, Met. Mater. Int. (2020). https://doi.org/10.1007/s12540-020-00655-3

Y.A. Alshataif, S. Sivasankaran, F.A. Al-Mufadi, A.S. Alaboodi, H.R. Ammar, Met. Mater. Int. (2019). https://doi.org/10.1007/s12540-019-00565-z

K.R. Lim, H.J. Kwon, J.-H. Kang, J.W. Won, Y.S. Na, Mater. Sci. Eng. A 771, 138638 (2020)

A.J. Zaddach, R.O. Scattergood, C.C. Koch, Mater. Sci. Eng. A 636, 373–378 (2015)

F. Otto, A. Dlouhý, C. Somsen, H. Bei, G. Eggeler, E.P. George, Acta Mater. 61, 5743–5755 (2013)

J.W. Won, S. Lee, S.H. Park, M. Kang, K.R. Lim, C.H. Park, Y.S. Na, J. Alloys Compd. 742, 290–295 (2018)

G. Laplanche, A. Kostka, O.M. Horst, G. Eggeler, E.P. George, Acta Mater. 118, 152–163 (2016)

J.W. Won, J.H. Lee, J.S. Jeong, S.-W. Choi, D.J. Lee, J.K. Hong, Y.-T. Hyun, Scr. Mater. 178, 94–98 (2020)

S.-W. Choi, J.W. Won, S. Lee, J.K. Hong, Y.S. Choi, Mater. Sci. Eng. A 738, 75–80 (2018)

ISO, ISO 1143:2010 Metallic Mterials—Rotary Bar Bending Fatigue Testing, BSI (2010)

M.D. Chapetti, H. Miyata, T. Tagawa, T. Miyata, M. Fujioka, Mater. Sci. Eng. A 381, 331–336 (2004)

M.R. Mitchell, Fatigue and Fracture (ASM International, Materials Park, 1996)

Y.Z. Tian, S.J. Sun, H.R. Lin, Z.F. Zhang, J. Mater. Sci. Technol. 35, 334–340 (2019)

Y.-K. Kim, G.-S. Ham, H.S. Kim, K.-A. Lee, Intermetallics 111, 106486 (2019)

S. Suresh, Fatigue of Materials (Cambridge University Press, Cambridge, 1998)

M. Liu, Z. Liu, S. Bai, P. Xia, P. Ying, S. Zeng, Int. J. Fatigue 84, 104–112 (2016)

H. Mughrabi, Acta Mater. 61, 1197–1203 (2013)

R. Liu, Z.J. Zhang, P. Zhang, Z.F. Zhang, Acta Mater. 83, 341–356 (2015)

R.H. Li, Z.J. Zhang, P. Zhang, Z.F. Zhang, Acta Mater. 61, 5857–5868 (2013)

Z.F. Zhang, Z.G. Wang, Mater. Sci. Eng. A 284, 285–291 (2000)

P. Zhang, S. Qu, Q.Q. Duan, S.D. Wu, S.X. Li, Z.G. Wang, Z.F. Zhang, Philos. Mag. 91, 229–249 (2011)

L.L. Li, Z.J. Zhang, P. Zhang, J.B. Yang, Z.F. Zhang, Acta Mater. 120, 120–129 (2016)

B. Wang, P. Zhang, Q.Q. Duan, Z.J. Zhang, H.J. Yang, J.C. Pang, Y.Z. Tian, X.W. Li, Z.F. Zhang, Mater. Sci. Eng. A 679, 258–271 (2017)

S. Hashimoto, H. Ikehata, A. Kato, H. Kato, Y. Kaneko, Interface Sci. 7, 159–171 (1999)

L. Llanes, C. Laird, Mater. Sci. Eng. A 157, 21–27 (1992)

S. Qu, P. Zhang, S.D. Wu, Q.S. Zang, Z.F. Zhang, Scr. Mater. 59, 1131–1134 (2008)

M.D. Sangid, H.J. Maier, H. Sehitoglu, Int. J. Plast. 27, 801–821 (2011)

B. Wang, Z.J. Zhang, C.W. Shao, Q.Q. Duan, J.C. Pang, H.J. Yang, X.W. Li, Z.-F. Zhang, Metall. Mater. Trans. A 46, 3317–3323 (2015)

A.l. Thompson, Acta Metall. 20, 1085–1094 (1972)

A.C. Lewis, K.A. Jordan, A.B. Geltmacher, Metall. Mater. Trans. A 39, 1109–1117 (2008)

I.P. Semenova, A.V. Polyakov, V.V. Polyakova, Y. Huang, R.Z. Valiev, T.G. Langdon, Adv. Eng. Mater. 18, 2057–2062 (2016)

R. Naseri, H. Hiradfar, M. Shariati, M. Kadkhodayan, Arch. Civ. Mech. Eng. 18, 755–767 (2018)

A.S. Hamada, L.P. Karjalainen, A. Ferraiuolo, J. Gil Sevillano, F. de las Cuevas, G. Pratolongo, M. Reis, Metall. Mater. Trans. A 41, 1102–1108 (2010)

D.-H. Jeong, S.-G. Lee, W.-K. Jang, J.-K. Choi, Y.-J. Kim, S. Kim, Metall. Mater. Trans. A 44, 4601–4612 (2013)

H. Sung, D. Jeong, T. Park, J. Lee, S. Kim, Met. Mater. Int. 22, 755–763 (2016)

M. Abareshi, E. Emadoddin, Mater. Des. 32, 5099–5105 (2011)

M.A. Islam, S. Chen, Y. Tomota, J. Mater. Eng. Perform. 16, 248–253 (2007)

Acknowledgements

This work was supported by the Ministry of Science, ICT and Future Planning (Republic of Korea) [Grant No. NRF-2016M3D1A1023534].

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lee, G.T., Won, J.W., Lim, K.R. et al. Effect of Microstructural Features on the High-Cycle Fatigue Behavior of CoCrFeMnNi High-Entropy Alloys Deformed at Room and Cryogenic Temperatures. Met. Mater. Int. 27, 593–602 (2021). https://doi.org/10.1007/s12540-020-00786-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00786-7