Abstract

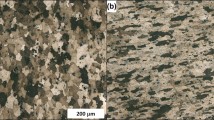

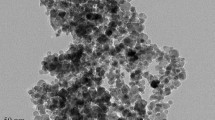

The high-entropy alloy particles reinforced 6061Al composite was prepared by cold spray (CS) and then modified by friction stir processing (FSP). The microstructure evolutions, corrosion, and wear behaviors of the composites were investigated. Results showed that numerous micro-pores and cracks were distributed in the Al matrix due to adiabatic shear instability and insufficient deformation of the deposited particles for CSed samples. The average size of uniformly distributed HEA particles was ~ 24 μm, and the geometric necessary dislocation (GND) density reached 17.1 × 1015 m−2 due to large plastic deformation during CS. Comparatively, the micro-pores and cracks were eliminated, and many fragmented HEA particles dispersed in the Al matrix with an average size of ~ 4 μm for FSPed sample. Note that the GND density reduced to 9.8 × 1015 m−2 due to dynamic recrystallization during FSP. The formation rate of the oxide film was gradually greater than that of the dissolution rate with the samples immersion in 3.5 wt% NaCl solution from 12 to 36 h, and the main corrosion mechanism was particle dissolution around micro-pores and pitting for CSed and FSPed samples, respectively. In the polarization process, the FSPed samples exhibited low corrosion tendency and high corrosion rate due to the dense and uniform microstructure, low GND density, and dispersed HEA particles. The FSPed samples had better wear resistance than the CSed samples at 25 °C and 200 °C. The dominant wear mechanisms of CSed and FSPed samples were abrasion at 25 °C, while the wear mechanisms of these samples were adhesion accompanied by abrasion at 200 °C.

Graphical Abstract

Similar content being viewed by others

References

N. Abu-warda, M.D. López, B. González, E. Otero, M.D. Escalera-Rodríguez, S. Cruz, P. Rey, D. Verdera, M.V. Utrilla, Precipitation hardening and corrosion behavior of friction stir welded A6005-TiB2 nanocomposite. Met. Mater. Int. 27, 2867–2878 (2021). https://doi.org/10.1016/j.msea.2017.11.068

Z.W. Yuan, W.B. Tian, F.G. Li, Q.Q. Li, Y.B. Hu, X.G. Wang, Microstructure and properties of high-entropy alloy reinforced aluminum matrix composites by spark plasma sintering. J. Alloy. Compd. 806, 901–908 (2019). https://doi.org/10.1016/j.jallcom.2019.07.185

J.P. Oliveira, J.F. Duarte, P. Inácio, N. Schell, R.M. Miranda, T.G. Santos, Production of Al/NiTi composites by friction stir welding assisted by electrical current. Mater. Des. 113, 311–318 (2017). https://doi.org/10.1016/j.matdes.2016.10.038

M. Dixit, J.W. Newkirk, R.S. Mishra, Properties of friction stir-processed Al 1100-NiTi composite. Scripta Mater. 56, 541–544 (2007). https://doi.org/10.1016/j.scriptamat.2006.11.006

J.P. Oliveira, T.M. Curado, Z. Zeng, J.G. Lopes, E. Rossinyol, J.M. Park, N. Schell, F.M. Braz Fernandes, H.S. Kim, Gas tungsten arc welding of as-rolled CrMnFeCoNi high entropy alloy. Mater. Des. 189, 108505 (2020). https://doi.org/10.1016/j.matdes.2020.108505

A.C. Martin, J.P. Oliveira, C. Fink, Elemental effects on weld cracking susceptibility in AlxCoCrCuyFeNi high-entropy alloy. Metall. Mater. Trans. A 51, 778–787 (2020). https://doi.org/10.1007/s11661-019-05564-8

J.P. Oliveira, J.J. Shen, Z. Zeng, J.M. Park, Y.T. Choi, N. Schell, E. Maawad, N. Zhou, H.S. Kim, Dissimilar laser welding of a CoCrFeMnNi high entropy alloy to 316 stainless steel. Scripta Mater. 206, 114219 (2022). https://doi.org/10.1016/j.scriptamat.2021.114219

P. Han, W. Wang, Z.H. Liu, T. Zhang, Q. Liu, X.H. Guan, K. Qiao, D.M. Ye, J. Cai, Y.C. Xie, K.S. Wang, Modification of cold-sprayed high-entropy alloy particles reinforced aluminum matrix composites via friction stir processing. J. Alloy. Compd. 907, 164426 (2022). https://doi.org/10.1016/j.jallcom.2022.164426

G.M. Karthik, S. Panikar, G.D. Janaki Ram, R.S. Kottada, Additive manufacturing of an aluminum matrix composite reinforced with nanocrystalline high-entropy alloy particles. Mater. Sci. Eng. A 679, 193–203 (2017). https://doi.org/10.1016/j.msea.2016.10.038

Y.Z. Liu, J. Chen, Z. Li, X.H. Wang, X.H. Fan, J.G. Liu, Formation of transition layer and its effect on mechanical properties of AlCoCrFeNi high-entropy alloy/Al composites. J. Alloy. Compd. 780, 558–564 (2019). https://doi.org/10.1016/j.jallcom.2018.11.364

E. Ananiadis, K.T. Argyris, T.E. Matikas, A.K. Sfikas, A.E. Karantzalis, Microstructure and corrosion performance of aluminium matrix composites reinforced with refractory high-entropy alloy particulates. Appl. Sci. 11, 1300–1312 (2021). https://doi.org/10.3390/app11031300

Q.L. Liu, X.P. Bao, S. Zhao, Y.Q. Zhu, Y.F. Lan, The influence of AlFeNiCrCoTi high-entropy alloy on microstructure, mechanical properties and tribological behaviors of aluminum matrix composite. Int. J. Metalcast. 15, 281–291 (2021). https://doi.org/10.1007/s40962-020-00462-x

W. Wang, P. Han, Y.H. Wang, T. Zhang, P. Peng, K. Qiao, Z. Wang, Z.H. Liu, K.S. Wang, High-performance bulk pure Al prepared through cold spray-friction stir processing composite additive manufacturing. J. Mater. Res. Technol. 9, 9073–9079 (2020). https://doi.org/10.1016/j.jmrt.2020.06.034

X.L. Xie, B. Hosni, C.Y. Chen, H.J. Wu, Y.L. Li, Z. Chen, C. Verdy, O.E.I. Kedim, Q.D. Zhong, A. Addad, C. Coddet, G. Ji, H.L. Liao, Corrosion behavior of cold sprayed 7075Al composite coating reinforced with TiB2 nanoparticles. Surf. Coat. Technol. 404, 126460 (2020). https://doi.org/10.1016/j.surfcoat.2020.126460

D.L. Cong, Z.S. Li, Q.B. He, H.B. Chen, Z.P. Zhao, L.P. Zhang, H.L. Wu, Wear behavior of corroded Al-Al2O3 composite coatings prepared by cold spray. Surf. Coat. Technol. 326, 247–254 (2017). https://doi.org/10.1016/j.surfcoat.2017.07.063

G.S. Huang, W. Fu, L. Ma, X.B. Li, H.R. Wang, Cold spraying B4C particles reinforced aluminium coatings. Surf. Eng. 35, 772–783 (2019). https://doi.org/10.1080/02670844.2018.1553135

J.M. Shockley, S. Descartes, P. Vo, E. Irissou, R.R. Chromik, The influence of Al2O3 particle morphology on the coating formation and dry sliding wear behavior of cold sprayed Al-Al2O3 composites. Surf. Coat. Technol. 270, 324–333 (2015). https://doi.org/10.1016/j.surfcoat.2015.01.057

W. Wang, P. Han, P. Peng, T. Zhang, Q. Liu, S.N. Yuan, L.Y. Huang, K. Qiao, K.S. Wang, Friction stir processing of magnesium alloys: A review. Acta Metall. Sin-Engl. 33, 43–57 (2020). https://doi.org/10.1007/s40195-019-00971-7

X.L. Xie, C.Y. Chen, Z. Chen, W. Wang, S. Yin, G. Ji, H.L. Liao, Achieving simultaneously improved tensile strength and ductility of a nano-TiB2/AlSi10Mg composite produced by cold spray additive manufacturing. Compos. Part B-Eng. 202, 108404 (2020). https://doi.org/10.1016/j.compositesb.2020.108404

K. Yang, W.Y. Li, P.L. Niu, X.W. Yang, Y.X. Xu, Cold sprayed AA2024/Al2O3 metal matrix composites improved by friction stir processing: microstructure characterization, mechanical performance and strengthening mechanisms. J. Alloy. Compd. 736, 115–123 (2018). https://doi.org/10.1016/j.jallcom.2017.11.132

K. Yang, W.Y. Li, Y.X. Xu, X.W. Yang, Using friction stir processing to augment corrosion resistance of cold sprayed AA2024/Al2O3 composite coatings. J. Alloy. Compd. 774, 1223–1232 (2019). https://doi.org/10.1016/j.jallcom.2018.09.386

C.J. Huang, W.Y. Li, Z.H. Zhang, M. Fu, M.P. Planche, H.L. Liao, G. Montavon, Modification of a cold sprayed SiCp/Al5056 composite coating by friction stir processing. Surf. Coat. Technol. 296, 69–75 (2016). https://doi.org/10.1016/j.surfcoat.2016.04.016

B. Zahmatkesh, M.H. Enayati, A novel approach for development of surface nanocomposite by friction stir processing. Mater. Sci. Eng. A 527, 6734–6740 (2010). https://doi.org/10.1016/j.msea.2010.07.024

M.V.N.V. Satyanarayana, K. Adepu, K. Chauhan, Effect of overlapping friction stir processing on microstructure, mechanical properties and corrosion behavior of AA6061 alloy. Met. Mater. Int. 27, 3563–3573 (2021). https://doi.org/10.1007/s12540-020-00757-y

C. Marion, P. Dirk, D. Eralp, R. Dierk, Orientation gradients and geometrically necessary dislocations in ultrafine grained dual-phase steels studied by 2D and 3D EBSD. Mater. Sci. Eng. A 527, 2738–2746 (2010). https://doi.org/10.1016/j.msea.2010.01.004

W.S. Miller, F.J. Humphreys, Strengthening mechanisms in particulate metal matrix composites. Scripta Metall. Mater. 25, 33–38 (1991). https://doi.org/10.1016/0956-716X(91)90349-6

G.J. Cui, Y. Qian, G.X. Bian, G.J. Gao, M. Hassani, Y.P. Liu, Z.M. Kou, CoCrNi matrix high-temperature wear resistant composites with micro- and nano-Al2O3 reinforcement. Compos. Commun. 22, 100461 (2020). https://doi.org/10.1016/j.coco.2020.100461

Y.P. Zhang, Q. Wang, G. Chen, C.S. Ramachandran, Mechanical, tribological and corrosion physiognomies of CNT-Al metal matrix composite (MMC) coatings deposited by cold gas dynamic spray (CGDS) process. Surf. Coat. Technol. 403, 126380 (2020). https://doi.org/10.1016/j.surfcoat.2020.126380

H. Fujii, Y.F. Sun, H. Kato, K. Nakata, Investigation of welding parameter dependent microstructure and mechanical properties in friction stir welded pure Ti joints. Mater. Sci. Eng. A 527, 3386–3391 (2010). https://doi.org/10.1016/j.msea.2010.02.023

A.E. Lekatou, A. Karantzalis, Evangelou, Aluminium reinforced by WC and TiC nanoparticles (ex-situ) and aluminide particles (in-situ): Microstructure, wear and corrosion behavior. Mater. Des. 65, 1121–1135 (2015). https://doi.org/10.1016/j.matdes.2014.08.040

A.K. Lekatou, A.E. Sfikas, D. Karantzalis, Sioulas, Microstructure and corrosion performance of Al-32%Co alloys. Corros. Sci. 63, 193–209 (2012). https://doi.org/10.1016/j.corsci.2012.06.002

A.G. Lekatou, A. Poulia, H. Mavros, A.E. Karantzalis, Thermal treatment, sliding wear and saline corrosion of Al in situ reinforced with Mg2Si and ex situ reinforced with TiC particles. J. Mater. Eng. Perform. 27, 5030–5039 (2018). https://doi.org/10.1007/s11665-018-3213-1

R. Udhayan, D.P. Bhatt, On the corrosion behaviour of magnesium and its alloys using electrochemical techniques. J. Power Sources 63, 103–107 (1996). https://doi.org/10.1016/S0378-7753(96)02456-1

M. Mahdavian, M.M. Attar, Another approach in analysis of paint coatings with EIS measurement: Phase angle at high frequencies. Corros. Sci. 48, 4152–4157 (2008). https://doi.org/10.1016/j.corsci.2006.03.012

B. Seo, K.H. Song, K. Park, Corrosion properties of dissimilar friction stir welded 6061 aluminum and HT590 steel. Met. Mater. Int. 24, 1232–1240 (2018). https://doi.org/10.1007/s12540-018-0135-2

Y.K. Wei, X.T. Luo, Y. Ge, X. Chu, G.S. Huang, C.J. Li, Deposition of fully dense Al-based coatings via in-situ micro-forging assisted cold spray for excellent corrosion protection of AZ31B magnesium alloy. J. Alloy. Compd. 806, 1116–1126 (2019). https://doi.org/10.1016/j.jallcom.2019.07.279

K.J. Hodder, H. Izadi, A.G. McDonald, A.P. Gerlich, Fabrication of aluminum-alumina metal matrix composites via cold gas dynamic spraying at low pressure followed by friction stir processing. Mater. Sci. Eng. A 556, 114–121 (2012). https://doi.org/10.1016/j.msea.2012.06.066

Y. Liu, B. Jin, D.J. Li, X.Q. Zeng, J. Lu, Wear behavior of nanocrystalline structured magnesium alloy induced by surface mechanical attrition treatment. Surf. Coat. Technol. 261, 219–226 (2015). https://doi.org/10.1016/j.surfcoat.2014.11.026

S.C. Lim, M.F. Ashby, Overview no. 55 Wear-Mechanism maps. Acta Metall. 35, 1–24 (1987). https://doi.org/10.1016/0001-6160(87)90209-4

S. Ngai, T. Ngai, F. Vogel, W. Story, G.B. Thompson, L.N. Brewer, Saltwater corrosion behavior of cold sprayed AA7075 aluminum alloy coatings. Corros. Sci. 130, 231–240 (2018). https://doi.org/10.1016/j.corsci.2017.10.033

F.S. Da Silva, J. Bedoya, S. Dosta, N. Cinca, I.G. Cano, J.M. Guilemany, A.V. Benedetti, Corrosion characteristics of cold gas spray coatings of reinforced aluminum deposited onto carbon steel. Corros. Sci. 114, 57–71 (2017). https://doi.org/10.1016/j.corsci.2016.10.019

O. Meydanoglu, B. Jodoin, E. Sabri Kayali, Microstructure, mechanical properties and corrosion performance of 7075 Al matrix ceramic particle reinforced composite coatings produced by the cold gas dynamic spraying process. Surf. Coat. Technol. 235, 108–116 (2013). https://doi.org/10.1016/j.surfcoat.2013.07.020

X.W. Yang, W.Y. Li, S.Q. Yu, Y.X. Xu, K.W. Hu, Y.B. Zhao, Electrochemical characterization and microstructure of cold sprayed AA5083/Al2O3 composite coatings. J. Mater. Sci. Technol. 59, 117–128 (2020). https://doi.org/10.1016/j.jmst.2020.04.041

S. Kumar, A.A. Rao, Influence of coating defects on the corrosion behavior of cold sprayed refractory metals. Appl. Surf. Sci. 396, 760–773 (2017). https://doi.org/10.1016/j.apsusc.2016.11.022

S.O.R. Sheykholeslami, R.T. Mousavian, D. Brabazon, Corrosion behaviour of rolled A356 matrix composite reinforced with ceramic particles. Int. J. Mater. Res. 107, 1100–1111 (2016). https://doi.org/10.3139/146.111443

N.R. Wang, B. Wu, W.L. Wu, J. Li, C.H. Ge, Y.F. Dong, L.X. Zhang, Y. Wang, Microstructure and properties of aluminium-high entropy alloy composites fabricated by mechanical alloying and spark plasma sintering. Mater. Today Commun. 25, 101366 (2020). https://doi.org/10.1016/j.mtcomm.2020.101366

H.S. Arora, H. Singh, B.K. Dhindaw, Wear behaviour of a Mg alloy subjected to friction stir processing. Wear 303, 65–77 (2013). https://doi.org/10.1016/j.wear.2013.02.023

V.N.V. Munagala, S. Bessette, R. Gauvin, R.R. Chromik, Sliding wear of cold sprayed Ti6Al4V coatings: Effect of porosity and normal load. Wear 450–451, 203268 (2020). https://doi.org/10.1016/j.wear.2020.203268

S.A. Alidokht, R.R. Chromik, Sliding wear behavior of cold-sprayed Ni-WC composite coatings: Influence OF WC content. Wear 477, 203792 (2021). https://doi.org/10.1016/j.wear.2021.203792

Z. Tan, L. Wang, Y.F. Xue, P. Zhang, T.Q. Cao, X.W. Cheng, High-entropy alloy particle reinforced Al-based amorphous alloy composite with ultrahigh strength prepared by spark plasma sintering. Mater. Des. 909, 219–226 (2016). https://doi.org/10.1016/j.matdes.2016.07.086

X. Yang, Z.F. Yan, P. Dong, B.Y. Cheng, J. Zhang, T.T. Zhang, H.X. Zhang, W.X. Wang, Surface modification of aluminum alloy by incorporation of AlCoCrFeNi high entropy alloy particles via underwater friction stir processing. Surf. Coat. Technol. 385, 125438 (2020). https://doi.org/10.1016/j.surfcoat.2020.125438

H.H. Stott, High-temperature sliding wear of metals. Tribol. Int. 35, 489–495 (2002). https://doi.org/10.1016/S0301-679X(02)00041-5

N. Nemati, M. Emamy, O.V. Penkov, J. Kim, D.E. Kim, Mechanical and high temperature wear properties of extruded Al composite reinforced with Al13Fe4 CMA nanoparticles. Mater. Des. 90, 532–544 (2016). https://doi.org/10.1016/j.matdes.2015.11.001

Acknowledgements

The authors gratefully acknowledge the National Natural Science Foundation of China [Nos. 51974220, 52001078, 52104383, 52034005], the National Key Research and Development Program of China[2021YFB3700902], and the Guangdong Basic and Applied Basic Research Foundation [2019B1515120016].

Author information

Authors and Affiliations

Contributions

Peng Han performed the major experiment and wrote the main manuscript. Jia Lin performed the experiment and explained the phenomena of the experiment. Zhihao Liu, Yating Xiang and Ting Zhang analyzed the data. Qiang Liu, Ke Qiao and Xiaohu Guan gave the technical support and revised the manuscript. Wen Wang, Yingchun Xie and Kuaishe Wang provided the financial support and gave a lot of advises for the experiment and paper, in addition, they also revised the manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Han, P., Lin, J., Wang, W. et al. Friction Stir Processing of Cold-Sprayed High-Entropy Alloy Particles Reinforced Aluminum Matrix Composites: Corrosion and Wear Properties. Met. Mater. Int. 29, 845–860 (2023). https://doi.org/10.1007/s12540-022-01248-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-022-01248-y