Abstract

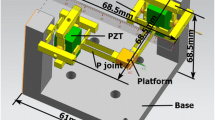

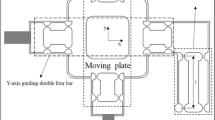

The non-bipolar operation of a stack-type piezo actuator causes non-bidirectional motion of the piezo-driven stage. This paper proposes a piezo-driven XY stage with a monolithic compliant parallel mechanism for fully bidirectional operation. Four prismatic-prismatic flexure-based joint chains are arranged antagonistically at the four sides of a target platform of the XY stage. The motion of each axis is conducted by differential force between piezo actuators in two actuating mechanisms arranged at both sides of a target platform along the same axis. Due to this antagonistic arrangement, the home position of the target platform is at the center position of the full operating range, and the target platform is movable along the positive and negative directions from the home position. Mathematical modeling of the proposed compliant mechanism is performed using a matrix-based equation of motion. The compliant mechanism is designed to satisfy design constraints using the mathematical model, and the designed mechanism is then analyzed using the Finite Element Method (FEM). The proposed bidirectional operation of the piezo-driven XY stage is demonstrated and the performance of the stage is subsequently described in terms of the response time, bandwidth and resolution.

Similar content being viewed by others

References

Chen, L.-S., Yen, J.-Y., Chen, J. J. H., Kuo, F.-C., Chen, M.-S., Chen, Y.-Y., et al. (2013). Precision tracking of a piezo-driven stage by charge feedback control. Precision Engineering,37(4), 793–804.

Choi, K.-B., Lee, J. J., & Hata, S. (2010). A piezo-driven compliant stage with double mechanical amplification mechanisms arranged in parallel. Sensors and Actuators A: Physical,161(1–2), 173–181.

Physik Instrumente. (2010). Micropositioning, nanopositioning, nanoautomation: Solutions for cutting-edge technologies. Karlsruhe/Palmbach, Germany: Physik Instrumente Catalogue.

Piezomechanik. (2010). First steps towards piezoaction. Munich, Germany: Piezo-mechanik GmbH Catalogue.

Piezomechanik. (2011). Low voltage co-fired multilayer stacks, rings and chips for actuation. Munich, Germany: Piezomechanik GmbH Catalogue.

Smith, S. T. (2000). Flexures: Elements of elastic mechanisms. Amsterdam, Netherlands: Gordon and Breach Science Publishers.

Lobontiu, N. (2003). Compliant mechanisms: Design of flexure hinges. Cambridge: CRC Press LLC.

Paros, J. M., & Weisbord, L. (1965). How to design flexure hinges. Machine Design,37(5), 151–156.

Choi, K.-B., & Lee, J. J. (2005). Passive compliant wafer stage for single-step nano-imprint lithography. Review of Scientific Instruments,76, 075106.

Lobontiu, N., & Paine, J. S. N. (2002). Design of circular cross-section corner-filleted flexure hinges for three-dimensional complaint mechanisms. Journal of Mechanical Design,124(3), 479–484.

Lu, S.-S., & Yan, P. (2017). A stiffness modeling approach for multi-leaf spring mechanism supporting coupling error analysis of nano-stages. International Journal of Precision Engineering and Manufacturing,18(6), 863–870.

Choi, K.-B., & Kim, D.-H. (2006). Monolithic parallel linear compliant mechanism for two axes ultraprecision linear motion. Review of Scientific Instruments,77, 065106.

Yong, Y. K., Moheimani, W. O. R., Kenton, B. J., & Leang, K. K. (2012). High-speed flexure-guided nanopositioning: Mechanical design and control issues. Review of Scientific Instruments,83(12), 121101.

Choi, K.-B., Lee, J. J., Kim, G. H., & Lim, H. J. (2012). XY parallel compliant stage with compact configuration. Journal of Nanoscience and Nanotechnology,12(7), 5245–5251.

Choi, K.-B., Lee, J. J., Kim, G. H., & Lim, H. J. (2012). A compliant parallel mechanism with flexure-based joint chains for two translations. International Journal of Precision Engineering and Manufacturing,13(9), 1625–1632.

Kang, B. H., Wen, J. T. Y., Dagalakis, N. G., & Gorman, J. J. (2005). Analysis and design of parallel mechanisms with flexure joints. IEEE Transactions on Robotics,21(6), 1179–1185.

Li, Y., & Xu, Q. (2009). Modeling and performance evaluation of a flexure-based XY parallel micromanipulator. Mechanism and Machine Theory,44(12), 2127–2152.

Elmustafa, A. A., & Lagally, M. G. (2001). Flexural-hinge guided motion nanopositioner stage for precision machining: Finite element simulations. Precision Engineering,25(1), 77–81.

Huang, S.-C., & Dao, T.-P. (2016). Design and computational optimization of a flexure-based XY positioning platform using FEA-based response surface methodology. International Journal of Precision Engineering and Manufacturing,17(8), 1035–1048.

Dao, T.-P., & Huang, S.-C. (2017). Optimization of a two degree of freedom compliant mechanism using Taguchi method-based grey relational analysis. Microsystem Technologies,23(10), 4815–4830.

Juuti, J., Kordas, K., Lonnakko, R., Moilanen, V.-P., & Leppavuori, S. (2005). Mechanically amplified large displacement piezoelectric actuators. Sensors and Actuators A: Physical,120(1), 225–231.

Xu, W., & King, T. (1996). Flexure hinges for piezo actuator displacement amplifiers: Flexibility accuracy and stress considerations. Precision Engineering,19(1), 4–10.

Choi, S. B., Han, S. S., & Lee, Y. S. (2005). Fine motion control of a moving stage using a piezoactuator associated with a displacement amplifier. Smart Materials Structures,14(1), 222–230.

Pinskier, J., Shirinzadeh, B., Clark, L., Qin, Y., & Fatikow, S. (2016). Design, development and analysis of a haptic-enabled modular flexure-based manipulator. Mechatronics,40, 156–166.

Zubir, M. N. M., & Shirinzadeh, B. (2009). Development of a high precision flexure-based microgripper. Precision Engineering,33(4), 362–370.

Tian, Y., Shirinzadeh, B., Zhang, D., & Alici, G. (2009). Development and dynamic modelling of a flexure-based Scott-Russell mechanism for nano-manipulation. Mechanical Systems and Signal Processing,23(3), 957–978.

Niezrecki, C., Brei, D., Balakrishnan, S., & Moskalik, A. (2001). Piezoelectric actuation: state of the art. Shock and Vibration Digest,33(4), 269–280.

Ma, H.-W., Yao, S.-M., Wang, L.-Q., & Zhong, Z. (2006). Analysis of the displacement amplification ratio of bridge-type flexure hinge. Sensors and Actuators A: Physical,132(2), 730–736.

Kim, J. H., Kim, S. H., & Kwak, Y. K. (2003). Development of a piezoelectric actuator using a three-dimensional bridge-type hinge mechanism. Review of Scientific Instruments,74(5), 2918–2924.

Xu, Q., & Li, Y. (2011). Analytical modeling, optimization and testing of a compound bridge-type compliant displacement amplifier. Mechanism and Machine Theory,46(2), 183–200.

Choi, K.-B., Lee, J. J., Kim, G. H., Lim, H. J., & Kwon, S. G. (2018). Amplification ratio analysis of a bridge-type mechanical amplification mechanism based on a fully compliant model. Mechanism and Machine Theory,121, 355–372.

Liu, P.-B., Yan, P., Zhang, Z., & Leng, T.-T. (2015). Flexure-hinges guided nano-stage for precision manipulations: Design, modeling and control. International Journal of Precision Engineering and Manufacturing,16(11), 2245–2254.

Choi, K.-B., Lim, H. J., Kim, G. H., & Lee, J. J. (2014). A flexure-based scanner for a fully bidirectional operation driven by a differential piezo force. Journal of Mechanical Engineering Science,228(27), 3186–3199.

Choi, K.-B. (2005). Dynamics of a compliant mechanism based on flexure hinges. J. Mechanical Engineering Science,219, 225–235.

Acknowledgements

This research was supported by Korea Basic Science Institute (Grant No. D010400), and BioNano Health-Guard Research Center funded by the Ministry of Science and ICT(MSIT) of Korea as Global Frontier Project (Grant No. H-GUARD_ 2013M3A6B2078943).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Choi, KB., Lee, J., Kim, G. et al. Design and Analysis of a Flexure-Based Parallel XY Stage Driven by Differential Piezo Forces. Int. J. Precis. Eng. Manuf. 21, 1547–1561 (2020). https://doi.org/10.1007/s12541-020-00358-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-020-00358-0