Abstract

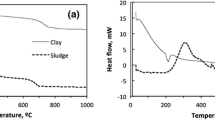

The disposal of clayey quarry sludges generated during aggregate washing process, represents significant environmental impacts and additional economic burden for the aggregate production industry. In this paper three different quarry sludges were sintered and investigated at the range 900–1100 °C using X-ray diffraction, thermogravimetric analysis, scanning electron microscopy, and Fourier-transform infrared spectroscopy. Blends of the considered quarry sludges were studied and their physical properties (density, shrinkage, water absorption and compressive strength) were assessed. The effect of firing temperature on these properties was estimated and linked to the microstructure changes during heat treatment. The results revealed that anorthite, hematite, portlandite and lime were the neoformed phases. Breakdown products of clay minerals and carbonates contributed to the formation of some of these phases. The measured properties were strongly influenced by the firing temperature. Considering the measured technological properties, ceramic bodies with good mechanical performances (70 MPa) could be manufactured in the aforementioned conditions.

Similar content being viewed by others

References

Galetakis, M., Soultana, A.: A review on the utilisation of quarry and ornamental stone industry fine by-products in the construction sector. Constr. Build. Mater. 102(Part 1), 769–781 (2016). doi:10.1016/j.conbuildmat.2015.10.204

Astm, C.: 33, Standard specification for concrete aggregates. Annu. Book Stand. 4 (1994)

BS EN, 12620, Aggregate for Concrete. London, British Standard Institute (2002)

Haach, V.G., Vasconcelos, G., Lourenço, P.B.: Influence of aggregates grading and water/cement ratio in workability and hardened properties of mortars., Constr. Build. Mater. 25, 2980–2987 (2011). doi:10.1016/j.conbuildmat.2010.11.011

Maletsika, P.A., Nanos, G.D., Stavroulakis, G.G.: Peach leaf responses to soil and cement dust pollution. Environ. Sci. Pollut. Res. 22, 15952–15960 (2015). doi:10.1007/s11356-015-4821-z

Zajec, L., Gradinjan, D., Klančnik, K., Gaberščik, A.: Limestone dust alters the optical properties and traits of Fagus sylvatica leaves. Trees 30, 2143–2152 (2016). doi:10.1007/s00468-016-1441-2

Zia-Khan, S., Spreer, W., Pengnian, Y., Zhao, X., Othmanli, H., He, X., Müller, J.: Effect of dust deposition on stomatal conductance and leaf temperature of cotton in northwest China. Water 7, 116–131 (2014). doi:10.3390/w7010116.

Singh, S., Khan, S., Khandelwal, R., Chugh, A., Nagar, R.: Performance of sustainable concrete containing granite cutting waste. J. Clean. Prod. 119, 86–98 (2016). doi:10.1016/j.jclepro.2016.02.008.

Ramos, T., Matos, A.M., Schmidt, B., Rio, J., Sousa-Coutinho, J.: Granitic quarry sludge waste in mortar: effect on strength and durability. Constr. Build. Mater. 47, 1001–1009 (2013). doi:10.1016/j.conbuildmat.2013.05.098

González-Corrochano, B., Alonso-Azcárate, J., Rodas, M.: Characterization of lightweight aggregates manufactured from washing aggregate sludge and fly ash. Resour. Conserv. Recycl. 53, 571–581 (2009). doi:10.1016/j.resconrec.2009.04.008.

Galetakis, M., Alevizos, G., Leventakis, K.: Evaluation of fine limestone quarry by-products, for the production of building elements—an experimental approach. Constr. Build. Mater. 26, 122–130 (2012). doi:10.1016/j.conbuildmat.2011.05.011

Raigon-Pichardo, M., Garcia-Ramos, G., Sánchez-Soto, P.J.: Characterization of a waste washing solid product of mining granitic tin-bearing sands and its application as ceramic raw material. Resour. Conserv. Recycl. 17, 109–124 (1996). doi:10.1016/0921-3449(96)01108-1.

Blanco García, I., Rodas, M., Sánchez, C.J., Dondi, M., Alonso-Azcárate, J.: Technological characterization and ceramic application of gravel pit by-products from middle-course Jarama river deposits (Central Spain). Appl. Clay Sci. 28, 283–295 (2005). doi:10.1016/j.clay.2004.01.013

ASTM: C326–test method for drying and firing shrinkage of ceramic whiteware clays. Am. Soc. Test. Mater. (1997)

ASTM: C373-88, standard test method water absorption bulk density apparent density apparent specific gravity of fired whiteware products. Am. Soc. Test. Mater. (1999)

ASTM: C39, standard test method for compressive strength of cylindrical concrete specimens. ASTM Int. (2001)

Loutou, M., Hajjaji, M., Mansori, M., Favotto, C., Hakkou, R.: Heated blends of phosphate waste: microstructure characterization, effects of processing factors and use as a phosphorus source for alfalfa growth. J. Environ. Manag. 177, 169–176 (2016)

Villieras, F., Yvon, J., Cases, J.M., De Donato, P., Lhote, F., Baeza, R.: Development of microporosity in clinochlore upon heating. Clays Clay Miner. 42, 679–688 (1994)

German, R.M.: Liquid Phase Sintering, Springer, New York (2013)

Venkatachalapathy, R., Gournis, D., Manoharan, C., Dhanapandian, S., Deenadayalan, K.: Application of FTIR and Mossbauer spectroscopy in analysis of some South Indian archaeological potteries. Indian J. Pure Appl. Phys. 41, 833–838 (2003)

Russell, J.D.: In: Wilson, M.J. (ed) Infrared Methods—A Hand Book of Determinative Methods in Clay Mineralogy, vol. 133. Blackie Son Ltd., New York (1987)

Maniatis, Y., Katsanos, A., Caskey, M.E.: Technological examination of low-fired terracotta statues from Ayia Irini, Kea. Archaeometry 24, 191–198 (1982)

Lavat, A.E., Grasselli, M.C., Tasca, J.E.: Phase changes of ceramic whiteware slip-casting bodies studied by XRD and FTIR. Ceram. Int. 33, 1111–1117 (2007)

Eliche-Quesada, D., Martínez-Martínez, S., Pérez-Villarejo, L., Iglesias-Godino, F.J., Martínez-García, C., Corpas-Iglesias, F.A.: Valorization of biodiesel production residues in making porous clay brick., Fuel Process. Technol. 103, 166–173 (2012). doi:10.1016/j.fuproc.2011.11.013

Samtani, M., Dollimore, D., Alexander, K.S.: Comparison of dolomite decomposition kinetics with related carbonates and the effect of procedural variables on its kinetic parameters. Thermochim. Acta 392–393, 135–145 (2002). doi:10.1016/S0040-6031(02)00094-1.

McIntosh, R.M., Sharp, J.H., Wilburn, F.W.: The thermal decomposition of dolomite. Thermochim. Acta 165, 281–296 (1990). doi:10.1016/0040-6031(90)80228-Q.

Khalfaoui, A., Hajjaji, M.: A Chloritic-illitic clay from Morocco: temperature–time–transformation and neoformation. Appl. Clay Sci. 45, 83–89 (2009). doi:10.1016/j.clay.2009.03.006

Aboufadil, Y., Hajjaji, M., A.E.I. Raghni, Thalal, A.: Heating transformations, technical properties and ceramic suitability of clays. Trans. Indian Ceram. Soc. 72, 201–205 (2013). doi:10.1080/0371750X.2013.851623

Linares, C.F., Sánchez, S., Urbina de Navarro, C., Rodríguez, K., Goldwasser, M.R.: Study of cancrinite-type zeolites as possible antacid agents. Microporous Mesoporous Mater. 77, 215–221 (2005). doi:10.1016/j.micromeso.2004.08.030

Gök, A., Omastová, M., Prokeš, J.: Synthesis and characterization of red mud/polyaniline composites: electrical properties and thermal stability. Eur. Polym. J. 43, 2471–2480 (2007). doi:10.1016/j.eurpolymj.2007.03.005

Hajjaji, M., Kacim, S., Alami, A., El Bouadili, A., El Mountassir, M.: Chemical and mineralogical characterization of a clay taken from the Moroccan Meseta and a study of the interaction between its fine fraction and methylene blue. Appl. Clay Sci. 20, 1–12 (2001). doi:10.1016/S0169-1317(00)00041-7

Wang, T., Chen, X., Lu, G.Q., Lei, G.Y.: Low-temperature sintering with nano-silver paste in die-attached interconnection. J. Electron. Mater. 36, 1333–1340 (2007). doi:10.1007/s11664-007-0230-5.

Grimshaw, R.W., Searle, A.B.: The Chemistry and Physics of Clays and Allied Ceramic Materials. Wiley, New York. http://www.bcin.ca/Interface/openbcin.cgi?submit=submit&Chinkey=1522 (1971). Accessed 10 Jan 2017

Quijorna, N., de Pedro, M., Romero, M., Andrés, A.: Characterisation of the sintering behaviour of Waelz slag from electric arc furnace (EAF) dust recycling for use in the clay ceramics industry., J. Environ. Manag. 132, 278–286 (2014). doi:10.1016/j.jenvman.2013.11.012

Acknowledgements

This work was supported in part by BATTUTA-Erasmus Mundus Programme.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Loutou, M., Hakkou, R., Argane, R. et al. Clayey Quarry Sludges: Thermal Transformation, Microstructure and Technological Properties. Waste Biomass Valor 9, 1805–1815 (2018). https://doi.org/10.1007/s12649-017-9972-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-017-9972-3