Abstract

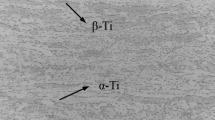

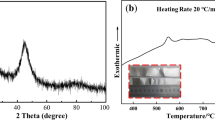

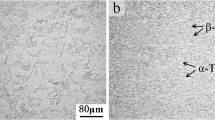

Vacuum brazing of TC4 titanium alloy and 316L stainless steel was conducted using Ag70.5Cu27.5Ti2 filler metal, the effects of microstructure and mechanical properties of brazing temperature on interface were investigated, and the bonding mechanism of brazed joint was also established. The results show that the filler metal and the base metal on both sides were completely diffused and bonded well. The microstructure of brazed joint interface is as follows: TC4 titanium alloy/diffusion layer(α-Ti + Ti2Cu)/reaction layer (including TiCu and Ti2Cu)/joint center area/TiFe layer/316L stainless steel. When the holding time lasted for 15 min, the shear strength of brazed joint first increased and then decreased as the brazing temperature rose. When the brazing temperature upped to 870 °C, the maximum of shear strength reached 190 MPa, and then the fracture occurred in the center of the brazed joint. The hardness of the joints gradually increased as the temperature rose, and the mean value reached maximum of 323 HV at 930 °C.

Similar content being viewed by others

References

Donachie M J, Rev Metal 46 (2002) 57.

Shapiro A, and Rabinkin A, Weld J 82 (2003) 36.

Boyer R R, Mater Sci Eng A 213 (1996) 103-114.

Gao M, Chen C, Wang L, Wang Z, and Zeng X, Metall Mater Trans A 46 (2015) 2007.

Satoh G, Yao Y L, and Qiu C, Int J Adv Manuf Technol 66 (2013) 469.

elmurugan C, Senthilkumar V, Sarala S, and Arivarasan, J, J Mater Process Technol 234 (2016) 272.

Deng Y Q, Sheng G G, and Xu C, Mater Des 46 (2013) 84.

Muralimohan C H, Ashfaq M, Ashiri R, Muthupandi, V, and Sivaprasad K, Metall Mater Trans A 47 (2016) 347.

Gao Y, Nakata K, Nagatsuka K, Liu F C, and Liao J, Mater Des 65 (2015) 17.

Kundu S, Ghosh M, and Chatterjee S, Mater Sci Eng A 428 (2006) 18.

Tashi R S, Mousavi S A A A, and Atabaki M M, Mater Des 54 (2014) 161.

Yue X, He P, Feng J C, Zhang J H, and Zhu F Q, Mater Charact 59 (2008) 1721.

Elrefaey A M, and Tillmann W, J Mater Sci 42 (2007) 9553.

Lee M K, Park J J, Lee J G, and Rhee C K, J Nucl Mater 439 (2013) 168.

Dezellus O, Arroyave R, and Fries S G, Inter J Mater Res 102 (2011) 286.

Laik A, Shirzadi A, Tewari R, Kumar Anish, Jayakumar T, and Dey G, Metall Mater Trans A 44 (2013) 2212.

Ganjeh E H, Sarkhosh H, Khorsand H, Sabet E H, Dehkordi M, and Ghaffari, Mater Des 39 (2012) 33.

Acknowledgements

This study was funded by College Students’ Extracurricular Open Experiment Project (KSZ18512) and the fund of State Key Laboratory of Long-life High Temperature Materials (DTCC28EE200795).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yang, M., Wu, X., Gong, X. et al. Interfacial Microstructure and Mechanical Properties of TC4 Titanium Alloy/316L Stainless Steel Joint Brazed with Ag70.5Cu27.5Ti2 Filler Metal. Trans Indian Inst Met 74, 1907–1916 (2021). https://doi.org/10.1007/s12666-021-02297-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-021-02297-4