Abstract

This paper proposes an improved robust position controller for the electro-hydraulic actuator system using the varying boundary layered sliding mode control scheme. The proposed scheme has the ability to improve the position tracking performance of the actuator in the presence of friction and internal leakage. The former is represented using the LuGre model while later is modelled as a turbulent flow. To evaluate the effectiveness of the proposed method, MATLAB simulations are carried out under friction and leakage effects. Its performance is compared with the conventional PID and fuzzy PID (FPID) methods. Finally, an experimental rig that comprises of a single-rod and double acting hydraulic cylinder is set up to validate the proposed idea. The software development is carried out in the DSpace 1104 environment using a TMS320F240 digital signal processor. The superiority of the proposed method over the PID and FPID in terms of tracking position is highlighted by simulation and experimental results.

Similar content being viewed by others

Abbreviations

- A 1, A 2 :

-

Cross-sectional area of the two chambers (m2)

- a :

-

Nonlinear dynamics

- \({\hat{a}}\) :

-

Estimation of nonlinear dynamics

- a p :

-

Piston acceleration (m/s2)

- \({\dot{a}_{\rm p}}\) :

-

Piston jerk (m/s3)

- b :

-

Control gain

- \({\hat {b}}\) :

-

Estimation of control gain

- b min :

-

Lower bound of control gain

- b max :

-

Upper bound of control gain

- C d :

-

Discharge coefficient

- C v1, C v1 :

-

Valve orifice coefficients

- d u :

-

External disturbance

- D :

-

Maximum disturbance

- e :

-

Error trajectory

- \({\dot{e}}\) :

-

Derivative of error

- E :

-

Error bounded

- F a :

-

Hydraulic actuating force (N)

- F c :

-

Coulomb friction (N)

- F f :

-

Hydraulic friction force (N)

- \({\dot{F}_{\rm f}}\) :

-

Derivative of friction force

- F s :

-

Stiction force (N)

- f d :

-

Lumped uncertain nonlinearities

- \({\dot{f}_{\rm d}}\) :

-

Derivative of lumped uncertain nonlinearities

- I max :

-

Max. current for servo valve

- k a :

-

Servo valve gain (m/V)

- K f1, K f2 :

-

Flow gain at control ports 1 and 2

- K 1R, K 2R :

-

Flow gain at return ports 1 and 2

- K 1S, K 2S :

-

Flow gain at supply ports 1 and 2

- k f1, k f2 :

-

Leakage coefficient at ports 1 and 2

- k 1R, k 2R :

-

Leakage coefficient at return ports1 and 2

- k 1S, k 2S :

-

Leakage coefficient at supply ports 1 and 2

- k v :

-

Viscous friction (N s/m)

- m :

-

Total mass of piston and load (kg)

- \({\dot{p}_l, \dot{p}_2}\) :

-

Derivative of pressure in chambers 1 and 2 (Pa/s)

- p r :

-

Return pressure (Pa)

- p s :

-

Supply pressure (Pa)

- p 1, p 2 :

-

Pressure in chambers 1 and 2 (Pa)

- Q :

-

Discontinuous switching gain

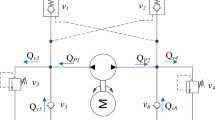

- Q S1, Q S2 :

-

Internal leakage flow in control ports 1 and 2 (m3/s)

- Q 1, Q 2 :

-

Fluid flow in chambers 1 and 2 (m3/s)

- Q 1R, Q 2R :

-

Return flow at return ports 1 and 2 (m3/s)

- Q 1S, Q 2S :

-

Supply flow at supply ports 1 and 2 (m3/s)

- Q max :

-

Maximum permissible flow (l/min)

- S :

-

Sliding surface

- \({\dot{S}}\) :

-

Derivative of sliding surface

- u :

-

Input signal to the servo valve (V)

- u eq :

-

Equivalent control signal (V)

- u sw :

-

Switching control signal (V)

- V :

-

Lyapunov function

- \({\dot{V}}\) :

-

Derivative of Lyapunov function

- v p :

-

Piston velocity (m/s)

- v s :

-

Stribeck velocity (m/s)

- V 1, V 2 :

-

Total actuator volume in chambers 1 and 2 (m3)

- V i1, V i2 :

-

Initial volume in chambers 1 and 2 (m3)

- w 1,w 2 :

-

Spool valve area gradients (m2)

- x d :

-

Desired position (m)

- x p :

-

Piston position (m)

- x v :

-

Spool valve displacement (m)

- \({\dot{x}_{\rm v}}\) :

-

Spool valve velocity (m/s)

- \({\ddot{x}_{\rm v}}\) :

-

Spool valve acceleration (m/s2)

- x 0 :

-

Equivalent orifice opening (m)

- \({\dot{x}_{\rm p}}\) :

-

Piston velocity (m/s)

- z :

-

Average of bristle deflection

- \({\dot{z}}\) :

-

Derivative of average of bristle deflection

- \({\omega_{\rm v}}\) :

-

Servo valve natural frequency (Hz)

- \({\beta _{\rm e}}\) :

-

Effective bulk modulus (Pa)

- \({\zeta_{\rm v}}\) :

-

Servo valve damping ratio

- \({\tau_{\rm v}}\) :

-

Time constant (s)

- \({\phi}\) :

-

Thickness of boundary layer

- \({\phi_{a}}\) :

-

1st level of boundary layer

- \({\phi_b}\) :

-

2nd level of boundary layer

- \({\sigma_{0}}\) :

-

Bristles stiffness coefficient (N/m)

- \({\sigma_{1}}\) :

-

Bristles damping coefficient (N s/m)

- \({\rho}\) :

-

Fluid mass density (kg/m3)

- \({\varepsilon _{\rm f}}\) :

-

Switching threshold of the tracking error

References

Canudas de Wit, C., Olsson, H., Astrom, K.J., Lischinsky, P.: A new model for control of systems with friction. IEEE Trans. Autom. Control. 40(3), 419–425 (1995)

Olsson, H., Astrom, K.J., Cadunas de Wit, C., Gafvert, M., Lischinsky, P.: Friction models and friction compensation. Eur. J. Control. 4(3), 176–195 (1998)

Erylmaz B., Wilson B.H.: Combining leakage and orifice flows in a hydraulic servo valve model. ASME J. Dyn. Syst. Meas. Contr. 122, 576–579 (2000)

Bobrow J.E., Lum K.: Adaptive high bandwidth control of a hydraulic actuator. ASME J. Dyn. Syst. Meas. Control. 118(4), 714–720 (1996)

Plummer R., Vaughan N.D.: Robust adaptive control for hydraulic servo systems. ASME J. Dyn. Syst. Meas. Contr. 118(2), 237–244 (1996)

Li, D.; Salcuden, S.E.: Modeling simulation and control of a hydraulic steward platform. In: Proc. of 1997 IEEE Int. Conf. Robot Automation, New Mexico, pp. 3360–3366 (1997)

Yun I.S., Cho H.S.: Adaptive model following control of electro-hydraulic velocity control system. Proc. Inst. Elect. Eng. 135(2), 149–156 (1998)

Tafazoli S., De Silva C.W., Lawrence P.D.: Tracking control of an electrohydraulic manipulator in the presence of friction. IEEE Trans. Control Syst. Technol. 6(3), 401–411 (1998)

Lischinsky, P.; Canudas de Wit, C.; Morel, G.: Friction compensation for an industrial hydraulic robot. IEEE Control Syst., February, 25–32 (1999)

Sekhavat, P.; Wu, Q.; Sepehri, N.: Lyapunov-based friction compensation for accurate positioning of a hydraulic actuator. In: Proceedings of the 2004 American Control Conference, Boston, Massachusetts, USA. June 30–July 2, pp. 418–423 (2004)

Iqbal S., Bhatti A.I.: Load varying polytopic based robust controller design in LMI framework for a 2DOF stabilized platform. Arab. J. Sci. Eng. 36(2), 311–327 (2011)

Rami A.M., Ismail A.M., Ibraheem K.I.: State-space based H-infinity robust controller design for boiler-turbine system. Arab. J. Sci. Eng. 37(6), 1767–1776 (2012)

Bonchis A., Corke P. I., Rye D.C., Ha Q.P.: Variable structure methods in hydraulic servos systems control. Automatica. 37, 589–595 (2001)

Mihajlov M., Nikolic V., Antic D.: Position control of electro hydraulic servo system using sliding mode control enhanced by Fuzzy PI controller. Facta Universitatis Ser. Mech. Eng. 1(9), 1217–1230 (2002)

Wang, S.; Habibi, S.; Burton, R.; Sampson, E.: Sliding mode control for a model of an electrohydraulic system with discontinuous nonlinear friction. In: Proceedings of the 2006 American Control Conference, pp. 418–423, Minneapolis, Minnesota, USA. June 14–16 (2006)

Zeng H., Sepehri N.: Tracking control of hydraulic actuators using LuGre friction model compensation. ASME J. Dynam. Syst. Meas. Contr. 130, 1–7 (2008)

Kalyoncu M., Haydim M.: Mathematical modelling and fuzzy logic based position control of an electrohydraulic servosystem with internal leakage. Mechatronics. 19, 847–858 (2009)

Ishaque K., Abdullah S.S., Ayub S., Salam Z.: Single input fuzzy logic controller for unmanned underwater vehicle. J. Intell. Robot. Syst. 59(1), 87–100 (2010)

Ishaque, K.; Abdullah, S.S.; Ayub, S.; Salam, Z.: A simplified approach to design fuzzy logic controller for an underwater vehicle. Ocean Eng. 38(1), 271–284 (2010)

Hung J.Y., Gao W., Hung J.C.: Variable structure control: a survey. IEEE Trans. Ind. Electron. 40(1), 2–21 (1993)

Eker I.: Second order sliding mode control with PI sliding surface and experimental application to an electromechanical plant. Arab. J. Sci. Eng. 37(7), 1969–1986 (2012)

Liu Y., Handroos H.: Technical note sliding mode control for a class of hydraulic position servo. Mechatronics. 9, 111–123 (1999)

Guan C., Pan S.: Adaptive sliding mode control of electro-hydraulic with nonlinear unknown parameters. Control Eng. Pract. 16, 1275–1284 (2008)

Chen H.-M., Renn J.-C., Su J.-P.: Sliding mode control with varying boundary layers for an electro-hydraulic position servo system. Int. J Adv. Manuf. Tech. 26, 117–123 (2005)

Zulfatman; Rahmat, M.F.: Application of self-tuning Fuzzy PID controller on industrial hydraulic actuator using system identification approach. Int. J. Smart Sens. Intell. Syst. 2(2), 246–261 (2009)

Merritt H.E.: Hydraulic control systems. Wiley, New York (1967)

Yao B., Bu F., Reedy J., Chiu G.T.-C.: Adaptive robust motion control of single-rod hydraulic actuators: theory and experiments. IEEE. ASMI Trans. Mechatron. 5(1), 79–91 (2000)

Jerzy W., Andrzej S., Marian W., Thomasz K.: Hysteretic effects of dry friction: modelling and experimental studies. Phil. Trans. R. Soc. A. 366, 747–765 (2008)

Hang C.C., Astrom K.J., Ho W.K.: Refinements of the Ziegler–Nichols tuning formula. IEE Proc.-D. 138(2), 111–118 (1991)

Buckner G.D.: Intelligent bounds on modelling uncertainty: applications to sliding mode control. IEEE Trans. Syst. Man. Cybern. Part C Appl. Rev. 32(2), 113–124 (2002)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Has, Z., Rahmat, M.F., Husain, A.R. et al. Robust Position Tracking Control of an Electro-Hydraulic Actuator in the Presence of Friction and Internal Leakage. Arab J Sci Eng 39, 2965–2978 (2014). https://doi.org/10.1007/s13369-013-0888-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-013-0888-3