Abstract

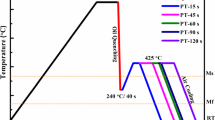

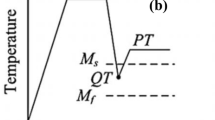

The novel quenching and partitioning processes concerned with the stabilization of carbon enriched austenite and provision of higher strength with higher toughness. The microstructural and mechanical properties of one-step quenched and partitioned 65Mn steel were investigated under various partitioning times, ranging from 30 to 600 s. The optical microscopy revealed that microstructure transformed from ferrite and pearlite to supersaturated lath martensite and retained austenite phases after one-step quenching and 30 s of partitioning. The unstable epsilon carbides were nucleated with the increase in partitioning time to 60 s and 180 s, whereas a further increase in partitioning time to 300 s transformed these unstable epsilon carbides into a stable cementite phase. Prolonged partitioning for 600 s produced carbon depleted martensite phase and nucleated ferrite phase. A maximum improvement of 88% in hardness and tensile strength and maximum reduction of 64% in elongation and 44% in impact toughness were achieved after 30 s of partitioning, compared to the as-received steel sample. On the other hand, partitioning for 600 s offered almost identical mechanical properties to the as-received steel. Partitioning for 180 s offered an optimum combination of mechanical properties of one-step quenched and partitioned 65Mn steel.

Similar content being viewed by others

References

Forouzan, F.; Vuorinen, E.; Mücklich, F.: Post weld-treatment of laser welded AHSS by application of quenching and partitioning technique. Mater. Sci. Eng., A 698, 174–182 (2017)

Wang, M.M.; Hell, J.C.; Tasan, C.C.: Martensite size effects on damage in quenching and partitioning steels. Scr. Mater. 138, 1–5 (2017)

Allain, S.Y.P.; Geandier, G.; Hell, J.C.; Soler, M.; Danoix, F.; Gouné, M.: In-situ investigation of quenching and partitioning by high energy X-ray diffraction experiments. Scr. Mater. 131, 15–18 (2017)

Zou, D.Q.; Lia, S.H.; He, J.: Temperature and strain rate dependent deformation induced martensitic transformation and flow behavior of quenching and partitioning steels. Mater. Sci. Eng., A 680, 54–63 (2017)

Chena, X.; Niu, C.; Lian, C.; Lin, J.: The evaluation of formability of the 3rd generation advanced high strength steels QP980 based on digital image correlation method. Procedia Eng. 207, 556–561 (2017)

Mohammed, B.; Park, T.; Pourboghrat, F.; Hu, J.; Esmaeilpour, R.; Farha, F.A.: Multiscale crystal plasticity modeling of multiphase advanced high strength steel. Int. J. Solids Struct. 151, 57–75 (2018)

Mohammed, B.; Park, T.; Kim, H.; Pourboghrat, F.; Esmaeilpour, R.: The forming limit curve for multiphase advanced high strength steels based on crystal plasticity finite element modeling. Mater. Sci. Eng., A 725, 250–266 (2018)

Knijf, D.D.; Föjer, C.; Kestens, L.A.I.; Petrov, R.: Factors influencing the austenite stability during tensile testing of quenching and partitioning steel determined via in situ electron backscatter diffraction. Mater. Sci. Eng., A 638, 219–227 (2015)

Paykani, M.A.; Shahverdi, H.R.; Miresmaeili, R.: First and third generations of advanced high-strength steels in a FeCrNiBSi system. J. Mater. Process. Technol. 238, 383–394 (2016)

Liu, Qinglong; Zhou, Qingjun; Venezuela, Jeffrey; Zhang, M.; Atrens, A.: Hydrogen influence on some advanced high-strength steels. Corros. Sci. 125, 114–138 (2017)

Kalhor, A.; Soleimani, M.; Mirzadeh, H.; Uthaisangsuk, V.: A review of recent progress in mechanical and corrosion properties of dual phase steels. Arch. Civ. Mech. Eng. 20, 85 (2020)

Soleimani, M.; Kalhor, A.; Mirzadeh, H.: Transformation-induced plasticity (TRIP) in advanced steels: a review. Mater. Sci. Eng., A 795, 140023 (2020)

Bhargava, M.; Tewari, A.; Mishra, S.K.: Forming limit diagram of advanced high strength steels (AHSS) based on strain-path diagram. Mater. Des. 85, 149–155 (2015)

Pourmajidian, M.; McDermid, J.R.: On the reactive wetting of a medium-Mn advanced high-strength steel during continuous galvanizing. Surf. Coat. Technol. 357, 418–426 (2019)

Park, T.; Hector, L.G.; Hu, J.X.; Farha, F.A.; Fellinger, M.R.; Kim, H.; Esmaeilpour, R.; Pourboghrat, F.: Crystal plasticity modeling of 3rd generation multi-phase AHSS with martensitic transformation. Int. J. Plast 120, 1–46 (2019)

Sun, W.W.; Wu, Y.X.; Yang, S.C.; Hutchinson, C.R.: Advanced high strength steel (AHSS) development through chemical patterning of austenite. Scr. Mater. 146, 60–63 (2018)

Srivastav, A.; Armaki, H.G.; Sung, H.; Chen, P.; Kumar, S.; Bower, A.F.: Micromechanics of plastic deformation and phase transformation in a three-phase TRIP-assisted advanced high strength steel: experiments and modeling. J. Mech. Phys. Solids 78, 46–69 (2015)

Wang, Z.; Wang, K.; Liu, Y.; Zhu, B.; Zhang, Y.; Li, S.: Multi-scale simulation for hot stamping quenching and partitioning process of high-strength steel. J. Mater. Process. Technol. 269, 150–162 (2019)

Nyyssonen, T.; Peur, P.; Moor, E.D.; Williamsond, D.; Kuokkal, V.T.: Crystallography and mechanical properties of intercritically annealed quench and partitioned high-aluminum steel. Mater. Charact. 148, 71–80 (2019)

Casero, C.C.; Kwakernaak, C.; Sietsma, J.: The influence of the austenite grain size on the microstructural development during quenching and partitioning processing of a low-carbon steel. Mater. Des. 178, 107847 (2019). https://doi.org/10.1016/j.matdes.2019.107847

Kong, H.; Chao, Q.; Rolfe, B.; Beladi, H.: One-step quenching and partitioning treatment of a tailor welded blank of boron and TRIP steels for automotive applications. Mater. Des. 174, 107799 (2019)

Kong, H.; Chao, Q.; Cai, M.H.; Pavlina, E.J.; Rolfe, B.; Hodgson, P.D.; Beladi, H.: One-step quenching and partitioning treatment of a commercial low silicon boron steel. Mater. Sci. Eng., A 707, 538–547 (2017)

Ebner, S.; Suppan, C.; Stark, A.; Schnitzer, R.; Hofer, C.: Austenite decomposition and carbon partitioning during quenching and partitioning heat treatments studied via in situ X-ray diffraction. Mater. Des. 178, 107862 (2019)

Peng, F.; Xu, Y.; Li, J.: Interaction of martensite and bainite transformations and its dependence on quenching temperature in intercritical quenching and partitioning steels. Mater. Des. 181, 107921 (2019)

Xia, P.; Vercruysse, F.; Petrov, R.; Sabirov, I.; Rodríguez, M.C.; Verleysen, P.: High strain rate tensile behavior of a quenching and partitioning (Q&P) Fe–0.25C–1.5Si–3.0Mn steel. Mater. Sci. Eng., A 745, 53–62 (2019)

Wang, H.; Zhao, Y.; Yuan, X.; Chen, K.; Xu, R.: Effects of boronizing treatment on corrosion resistance of 65mn steel in two acid mediums. Phys. Procedia 50, 124–130 (2013)

Wang, Y.; Sun, J.; Jiang, T.; Yang, C.; Tan, Q.; Guo, S.; Liu, Y.: Super strength of 65Mn spring steel obtained by appropriate quenching and tempering in an ultrafine grain condition. Mater. Sci. Eng., A 754, 1–8 (2019)

Chunjie, D.; Jianhua, Z.; Jiayuan, X.; Xichao, S.; Yunfeng, Z.: Microstructures and properties of electrical discharge strengthened layers on 65Mn steel. Appl. Surf. Sci. 257, 2843–2849 (2011)

Liu, C.; Zhao, Z.; Northwood, D.O.; Liu, Y.: A new empirical formula for the calculation of MS in pure iron super low alloy steels. J. Mater. Process. Technol. 113, 556–562 (2001)

Wendler, M.; Ullrich, C.; Hauser, M.; Krüger, L.; Volkova, O.; Wei, A.; Mola, J.: Quenching and partitioning (Q and P) processing of fully austenitic stainless steels. Acta Mater. 133, 346–355 (2017)

Santofimia, M.J.; Petrov, R.H.; Zhao, L.; Sietsma, J.: Microstructural analysis of martensite constituents in quenching and partitioning steels. Mater. Charact. 92, 91–95 (2014)

Tariq, F.; Baloch, R.A.: One-step quenching and partitioning heat treatment of medium carbon low alloy steel. J. Mater. Eng. Perform. 23, 1726–1739 (2014)

Elena P.; David V. Edmonds, Phase transformation in steels. woodhead 138 (2012)

Wang, C.Y.; Shi, J.; Cao, W.Q.; Dong, H.: Characterization of microstructure obtained by quenching and partitioning process in low alloy martensitic steel. Mater. Sci. Eng., A 527, 3442–3449 (2010)

Speer, J.G.: Phase transformation in quenched and partitioned steel. Phase Transf. Steel 2, 247–268 (2012)

Goerge E. Dieter, strengthening mechanisms in mechanical metallurgy book, 3rd edition 184–233 (2017)

Callister, W.D.; David, J.; Rethwisch, G.: Dislocation and strengthening mechanisms in material science and engineering an introduction book, 8th edition 188–191 (2009)

Hafeez, M.A.; Farooq, A.; Tayyab, K.B.; Arshad, M.A.: Effect of thermo-mechanical cyclic quenching and tempering treatments on microstructure, mechanical, and electrochemical properties of AISI 1345 steel. Int. J. Miner. Metall. Mater. (2020). https://doi.org/10.1007/s12613-020-2139-4

Hafeez, M.A.; Usman, M.; Arshad, M.A.; Umer, M.A.: Nanoindentation-based micro-mechanical and electrochemical properties of quench-hardened, tempered low-carbon steel. Crystals 10, 508 (2020)

Hafeez, M.A.: Investigation on mechanical properties and immersion corrosion performance of 0.35%C–10.5%Mn steel processed by austenite reverted transformation (ART) annealing process. Metallogr. Microstruct. Anal. 9, 159–168 (2020)

Hafeez, M.A.; Farooq, A.: Effect of heat treatments on the mechanical and electrochemical behavior of 38CrSi and AISI 4140 steels. Metallogr. Microstruct. Anal. 8, 479–487 (2019)

Hafeez, M.A.; Farooq, A.: Microstructural, mechanical and tribological investigation of 30CrMnSiNi2A ultra-high strength steel under various tempering temperatures. Mater. Res. Express 5, 016505 (2018)

Hafeez, M.A.: Effect of microstructural transformation during tempering on mechanical properties of quenched and tempered 38CrSi steel. Mater. Res. Express 6, 086552 (2019)

Abbaschian, R.; Abbaschian, L.; Reed-Hill, R.E.: Physical Metallurgy Principles, 4th edn, pp. 1–10. Cengage Learning, Stamford (2009)

Nishikawa, A.S.; Santofimia, M.J.; Sietsma, J.; Goldensein, H.: Influence of bainite reaction on the kinetics of carbon redistribution during the quenching and partitioning (Q & P) processing of medium Mn steel. Acta Mater. 107, 354–365 (2016)

Clarke, A.J.; Speer, J.G.; Matlock, D.K.; Rizzo, F.C.; Edmond, D.V.; Santofimin, M.J.: Influence of carbon partitioning kinetics on final austenite fraction during quenching and partitioning. Scr. Mater. 61, 149–152 (2009)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hafeez, M.A. Microstructural and Mechanical Properties of One-Step Quenched and Partitioned 65Mn Steel. Arab J Sci Eng 46, 2261–2267 (2021). https://doi.org/10.1007/s13369-020-05075-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-020-05075-4