Abstract

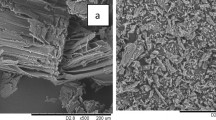

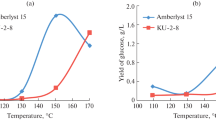

For the first time, the process of extraction fractionation of “hemicelluloses-free” birch wood in an ethanol medium into cellulose product and ethanol lignin is studied and optimized. The composition and structure of cellulose product and ethanol lignin obtained by extraction fractionation of “hemicellulose-free” birch wood and other products of their subsequent transformations are characterized by methods of infra-red spectroscopy, nuclear magnetic resonance, X-ray diffractometry, scanning electron microscopy, BET surface area analysis, high-performance liquid chromatography, gel permeation chromatography, gas chromatography, and chemical and elemental analysis. The possibility of producing enterosorbents from birch ethanol lignin that are more effective than the commercial enterosorbents “Polyphepan” based on hydrolyzed lignin is established. A new approach to the biorefinery of birch wood into xylose, levulinic acid and enterosorbents is proposed based on the integration of an optimized process of extraction fractionation of “hemicellulose-free” birch wood in ethanol medium, alkaline isolation of xylan and its hydrolysis to xylose, cellulose product conversion into levulinic acid and ethanol lignin processing to enterosorbents.

Similar content being viewed by others

References

Zhao X, Zhou H, Sikarwar VS, Zhao M, Park AHA, Fennell PS, Shen L, Fan LS (2017) Biomass-based chemical looping technologies: the good, the bad and the future. Energy Environ Sci 10(9):1885–1910. https://doi.org/10.1039/c6ee03718f

Den W, Sharma VK, Lee M, Nadadur G, Varma RS (2018) Lignocellulosic biomass transformations via greener oxidative pretreatment processes: access to energy and value-added chemicals. Front Chem 6:141. https://doi.org/10.3389/fchem.2018.00141

Banu JR, Preethi KS, Tyagi VК, Gunasekaran M, Karthikeyan OP, Kumar G (2021) Lignocellulosic biomass based biorefinery. Fuel 302(15):121086. https://doi.org/10.1016/j.fuel.2021.121086

Shen X, Sun R (2021) Recent advances in lignocellulose prior-fractionation for biomaterials, biochemicals, and bioenergy. Carbohyd Polym 261(1):117884. https://doi.org/10.1016/j.carbpol.2021.117884

Başakçılardan Kabakcı S, Tanış MH (2020) Pretreatment of lignocellulosic biomass at atmospheric conditions by using different organosolv liquors: a comparison of lignins. Biomass Conv Bioref. https://doi.org/10.1007/s13399-020-00677-2

Kuznetsov BN, Sudakova IG, Garyntseva NV, Tarabanko VE, Yatsenkova OV, Djakovitch L, Rataboul F (2021) Processes of catalytic oxidation for the production of chemicals from softwood biomass. Catal Today 375:132–144. https://doi.org/10.1016/j.cattod.2020.05

Van den Bosch S, Schutyser W, Vanholme R, Driessen T, Koelewijn SF, Renders T, De Meester B, Huijgen WJJ, Dehaen T, Courtin CM, Lagrain B, Boerjan W, Sels BF (2015) Reductive lignocellulose fractionation into soluble lignin-derived phenolic monomers and dimers and processable carbohydrate pulps. Energy Environ Sci 8(6):748–1763. https://doi.org/10.1039/c5ee00204d

Rowell RM (2012) Handbook of Wood Chemistry and Wood Composites (2nd ed.). CRC Press. https://doi.org/10.1201/b12487

Jin X, Hu Z, Wu S, Song T, Yue F, Xiang Z (2019) Promoting the material properties of Xylan-type hemicelluloses from the extraction step. Carbohyd Polym 215:235–245. https://doi.org/10.1016/j.carbpol.2019.03

Naidu DS, Hlangothi SP, John MJ (2018) Bio-based products from xylan: a review. Carbohyd Polym 179:28–41. https://doi.org/10.1016/j.carbpol.2017.09.0

Liu HM, Li YR, Wu M, Yin HS, Wang XD (2018) Two-step isolation of hemicelluloses from Chinese quince fruit: effect of hydrothermal treatment on structural features. Ind Crop Prod 111:615–624. https://doi.org/10.1016/j.indcrop.2017.11.035

Zhang W, Johnson AM, Barone JR, Renneckar S (2016) Reducing the heterogeneity of xylan through processing. Carbohyd Polym 150:250–258. https://doi.org/10.1016/j.carbpol.2016.05.013

Liu HM, Wang FY, Liu YL (2016) Hot-compressed water extraction of polysaccharides from soy hulls. Food Chem 202:104–109. https://doi.org/10.1016/j.foodchem.2016.01.129

Rashid R, Ejaz U, Ali FL, Hashmi LA, Bari A, Liu J, Wang L, Fu PC, Sohail M (2020) Combined pretreatment of sugarcane bagasse using alkali and ionic liquid to increase hemicellulose content and xylanase production. BMC Biotechnol 20. https://doi.org/10.1186/s12896-020-00657-4

Zhang K, Pei Z, Wang D (2016) Organic solvent pretreatment of lignocellulosic biomass for biofuels and biochemicals: a review. Biores Technol 199:21–33. https://doi.org/10.1016/j.biortech.2015.08

Malu TJ, Manikandan K, Cheralathan KK (2020) Chapter 6 - Levulinic acid—a potential keto acid for producing biofuels and chemicals. In Biomass, Biofuels, Biochemicals. Saravanamurugan S (ed) Elsevier, pp 171–197

Taran OP, Gromov NV, Parmon VN (2018) Chapter 2 - Catalytic Processes and Catalyst Development in Biorefining. In Sustainable Catalysis for Biorefineries. Frusteri F, Aranda D, Bonura G (ed) Royal Society of Chemistry, pp 25–64. https://doi.org/10.1039/9781788013567-00025

Zhang D, Zhao YP, Fan X, Liu ZQ, Wang RY, Wei XY (2018) Catalytic hydrogenation of levulinic acid into gamma-valerolactone over Ni/HZSM-5 catalysts. Catal Surv Asia 22(3):129–135. https://doi.org/10.1007/s10563-018-9246-5

Zhang K, Pei Z, Wang D (2016) Organic solvent pretreatment of lignocellulosic biomass for biofuels and biochemicals: a review. Bioresour Technol 199:21–33. https://doi.org/10.1016/j.biortech.2015.08.102

Andreo-Martínez P, Ortiz-Martínez VM, García-Martínez N, Hernández-Fernández FJ, Pérez de los Ríos A, Quesada-Medina J (2021) A simple fractionation method and GPC analysis of organosolv extracts obtained from lignocellulosic materials. Biomass Conv Bioref 11:1807–1821. https://doi.org/10.1007/s13399-019-00593-0

Markelov DA, Nitsak OV, Gerashchenko II (2008) Comparative study of adsorption activity medical sorbents. Pharm Chem J 42(7):30–33

Kuznetsov BN, Sudakova IG, Garyntseva NV, Tarabanko VE, Chesnokov NV, Djakovitch L, Rataboul F (2020) Kinetic studies and optimization of heterogeneous catalytic oxidation processes for the green biorefinery of wood. Top Catal 63:229–242

Kuznetsov BN, Baryshnikov SV, Miroshnikova AV, Kazachenko AS, Malyar YN, Skripnikov AM, Taran OP (2021) Fractionation of birch wood by integrating alkaline-acid treatments and hydrogenation in ethanol over a bifunctional ruthenium catalyst. Catalysts 11:1362

Torgashov VI, Solovieva LV, Zubets OV, Kaputsky FN (2014) Obtaining xylan of pharmaceutical quality from birch wood. BSU Bulletin. Series 2: Chemistry. Biology Geography 1:21–26

Quesada-Medina J, López-Cremades FJ, Olivares-Carrillo P (2010) Organosolv extraction of lignin from hydrolyzed almond shells and application of the d-value theory. Biores Technol 101:8252–8260. https://doi.org/10.1016/j.biortech.2010.06

Garyntseva NV, Sudakova IG, Kuznetsov BN (2011) Properties of enterosorbents obtained from acetic acid lignins of abies, aspen and birch wood. J Sib Fed Univ Chem 2(4):121–126

Ruiz-Matute AI, Hernández-Hernández O, Rodríguez-Sánchez S, Sanz ML, Martínez-Castro I (2011) Derivatization of carbohydrates for GC and GC–MS analyses. J Chromatogr B 879:1226–1240

Panthapulakkal S, Kirk D, Sain M (2015) Alkaline extraction of xylan from wood using microwave and conventional heating. J Appl Polymer Sci 132 (4). https://doi.org/10.1002/app.41330

Lian Z, Wang, Y, Luo J, Lai C, Yong Q, Yu S (2020) An integrated process to produce prebiotic xylooligosaccharides by autohydrolysis, nanofiltration and endo-xylanase from alkali-extracted xylan. Bioresource Technol: 123685. https://doi.org/10.1016/j.biortech.2020.12

Qaseem MF, Shaheen H, Wu A-M (2021) Cell wall hemicellulose for sustainable industrial utilization. Renew Sustain Energy Rev 144:110996. https://doi.org/10.1016/j.rser.2021.110996

Sharma K, Khaire KC, Thakur A, Moholkar VS, Goyal A (2020) Acacia Xylan as a substitute for commercially available Xylan and its application in the production of Xylooligosaccharides. ACS Omega 5(23):13729–13738. https://doi.org/10.1021/acsomega.0c00896

Bian J, Peng F, Peng X-P, Xu F, Sun R-C, Kennedy JF (2012) Isolation of hemicelluloses from sugarcane bagasse at different temperatures: structure and properties. Carbohyd Polym 88(2):638–645. https://doi.org/10.1016/j.carbpol.2012.01

Corradini FAS, Baldez TO, Milessi TSS, Tardioli PW, Ferreira AG, Campos Giordano GR, de de L C Giordano R (2018) Eucalyptus xylan: an in-house-produced substrate for xylanase evaluation to substitute birch wood xylan. Carbohyd Polym 197:167–173. https://doi.org/10.1016/j.carbpol.2018.05.088

Gabrielii I, Gatenholm P, Glasser WG, Jain RK, Kenne L (2000) Separation, characterization and hydrogel-formation of hemicellulose from aspen wood. Carbohyd Polym 43(4):367–374. https://doi.org/10.1016/s0144-8617(00)001

Johansson A, Aaltonen O, Ylinen P (1987) Organosolv pulping – methods and pulp properties. Biomass 13(1):45–65

Zhang Z, Harrison MD, Rackemann DW, Doherty WOS, O´Hara IM, (2016) Organosolv pretreatment of plant biomass for enhanced enzymatic saccharification. Green Chem 18:201660–202381

Pen RZ (2003) Planning an experiment in Statgraphics. - Krasnoyarsk: SibSTU-Claretianum

Fan M, Dai D, Huang B (2012). Fourier transform infrared spectroscopy for natural fbres. In: Salih S (ed) Fourier transform—material analysis. In Tech, Rejeka https://doi.org/10.5772/35482

Nam S, French AD, Condon BD, Concha M (2016) Segal crystallinity index revisited by the simulation of X-ray diffraction patterns of cotton cellulose Iβ and cellulose II. Carbohyd Polym 135:1–9. https://doi.org/10.1016/j.carbpol.2015.08.0

Park S, Baker JO, Himmel ME, Parilla PA, Jonson DK (2010) Cellulose crystallinity index: measurement techniques and their impact on interpreting cellulose performance. Biotechnol Biofuels 3:10. https://doi.org/10.1186/1754-6834-3-10

Mikova NM, Levdanskiy VA, Skwortsova GP, Zhizhaev AM, Lutoshkin MA, Chesnokov NV, Kuznetsov BN (2021) Structure and properties of organic xerogels derived from tannins and ethanol lignins of the Siberian fir. Biomass Conv Bioref 11:1565–1573. https://doi.org/10.1007/s13399-019-00561-8

Shi Z, Xu G, Deng J, Dong M, Murugadoss V, Liu Ch, Shao Q, Wu S, Guo Z (2019) Structural characterization of lignin from D sinicus by FTIR and NMR techniques. Green Chem Lett Rev 12(3):235–243. https://doi.org/10.1080/17518253.2019.1627428

Roeges NPG (1995) A guide to the complete interpretation of infrared specter of organic structures. Wiley New York, 340p

Pu Y, Cao S, Ragauskas AJ (2011) Application of quantitative 31P NMR in biomass lignin and biofuel precursors characterization. Energy Environ Sci 4(9):3154. https://doi.org/10.1039/c1ee01201k

Fiţigãu IF, Peter F, Boeriu CG (2013) Structural analysis of lignin from different sources Internation. J Chem Mol Nuclear Mater Metall Eng 7(4):167–172

Mäki-Arvela P, Salmi T, Holmbom B, Willför S, Murzin DYu (2011) Synthesis of sugars by hydrolysis of hemicelluloses — a review. Chem Rev 111(9):5638–5666

Hilpmann G, Bechera N, Pahner F-A, Kusema B, Mäki-Arvela P, Lange R, Murzin DYu, Salmi T (2016) Acid hydrolysis of xylan. Catal Today 259:376–380

Carà PD, Pagliaro M, Elmekawy A, Brown DR, Verschuren P, Shiju NR, Rothenberg G (2013) Hemicellulose hydrolysis catalysed by solid acids. Catal Sci Technol 3(8):2057–2061

Yatsenkova OV, Skripnikov AM, Kozlova SA, Kuznetsov BN (2018) Kinetic study and optimization of hydrolysis of larch arabinogalactan in the presence of dissolved and solid acid catalysts. J Sib Fed Univ Chem 2:167–183. https://doi.org/10.17516/1998-2836-0066

Yan K, Jarvis C, Gu J, Yan Y (2015) Production and catalytic transformation of levulinic acid: a platform for speciality chemicals and fuels. Renew Sustain Energy Rev 51:986–997. https://doi.org/10.1016/j.rser.2015.07.021

Hu X, Ming C, Sun K, Shao Y, Zhang Z, Zhang S, Xiang J (2019) Conversion of cellulose to levulinic acid/ester over acid catalyst: impacts of dispersion of hydrogen ions on polymerisation reactions. Energy Fuels. https://doi.org/10.1021/acs.energyfuels.9

Han Y, Ye L, Gu X, Zhu P, Lu X (2019) Lignin-based solid acid catalyst for the conversion of cellulose to levulinic acid using γ-valerolactone as solvent. Ind Crops Prod 127:88–93. https://doi.org/10.1016/j.indcrop.2018.10

Badgujar KC, Wilson LD, Bhanage BM (2019) Recent advances for sustainable production of levulinic acid in ionic liquids from biomass: Current scenario, opportunities and challenges. Renew Sustain Energy Rev 102:266–284. https://doi.org/10.1016/j.rser.2018.12.00

Girisuta B, Janssen LPBM, Heeres HJ (2006) A kinetic study on the decomposition of 5- hydroxymethylfurfural into levulinic acid. Green Chem 8:701–709

Acknowledgements

This study was carried out with the use of the equipment of Krasnoyarsk Regional Center of Research Equipment of the Federal Research Centre “Krasnoyarsk Science Centre SB RAS”.

Funding

The reported study was supported by the Russian Science Foundation, Grant No. 21–13-00250 https://rscf.ru/project/21-13-00250/.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing of interests

The authors declare no competing of interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kuznetsov, B.N., Sudakova, I.G., Chudina, A.I. et al. Fractionation of birch wood biomass into valuable chemicals by the extraction and catalytic processes. Biomass Conv. Bioref. 14, 2341–2355 (2024). https://doi.org/10.1007/s13399-022-02498-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-02498-x