Abstract

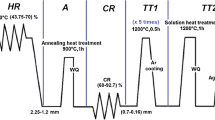

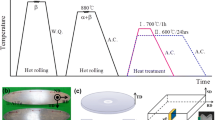

A compositional modification was initially carried out in Ti-6Al-4V alloy by substitution replacement of vanadium (V) by iron (Fe) as a β-stabilizing alloying element in order to develop Ti6Al(1-3)Fe alloys. Afterwards, Ti6Al(1-3)Fe alloys underwent rolling at 800 °C followed by solution heat treatment at 900 °C. Microstructural characterization reveals that Ti6Al(1-3)Fe alloys contain a lamellar α+β microstructure wherein size of lamellar colonies and the lamellae width gradually decrease by increasing Fe content. Subsequent thermo-mechanical and solution heat treatment lead to an increase in β-phase percentage by increasing Fe content. Ti6Al(1-3)Fe alloys show a superior hardness (HV), ultimate tensile strength (UTS) and elongation (%) owing to extensively refined lamellar α+β microstructure. HV values of Ti6Al(1-3)Fe alloys increase after thermo-mechanical treatment while UTS and elongation (%) values as well as corrosion properties drop due to the larger amount of β-phase in thermo-mechanical treated Ti6Al(1-3)Fe alloys.

Graphical Abstract

Similar content being viewed by others

References

V. Vaithiyanathan, V. Balasubramanian, S. Malarvizhi, V. Petley, S. Verma, Combined effect of Gas Tungsten Arc Welding process variants and post-weld heat treatment on tensile properties and microstructural characteristics of Ti–6Al–4V Alloy joints. Metallogr. Microstruct. Anal. 9, 194–211 (2020)

L. Wang, H. Ma, Q. Fan, J. Yao, X. Shen, S. Zhang, Y. Zhou, Y. Peng, Y. Gao, D. Wang, Simultaneously enhancing strength and ductility of Ti-6Al-4V alloy with the hierarchical structure via a novel thermal annealing treatment. Mater. Charact. 176, 111112 (2021)

P.P. Singh, R.K. Gupta, V.A. Kumar, R.C. Gundakaram, S.K. Singh, Tailoring the microstructure and mechanical properties of titanium alloy Ti6Al4V forgings with different combinations of thermo-mechanical processing and heat treatment cycles. Trans. Indian Natl. Acad. Eng. 6, 839–855 (2021)

C. Leyens, M. Peters, Titanium and Titanium Alloys: Fundamentals and Applications (Wiley, London, 2006)

J. Šmilauerová, J. Pospíšil, P. Harcuba, V. Holý, M. Janeček, Single crystal growth of TIMETAL LCB titanium alloy by a floating zone method. J. Cryst. Growth. 405, 92–96 (2014)

Z. Liang, J. Miao, T. Brown, A.K. Sachdev, J.C. Williams, A.A. Luo, A low-cost and high-strength Ti-Al-Fe-based cast titanium alloy for structural applications. Scrip. Mater. 157, 124–128 (2018)

H. Kadiri, L. Wang, H.O. Gulsoy, P. Suri, S. Park, Y. Hammi, R. German, Development of a Ti-based alloy: design and experiment. JOM. 61, 60–66 (2009)

F. Hideki, T. Kazuhiro, Development of high performance Ti-Fe-Al alloy series. Nippon. Steel. Tech. Rep. 74, 113–117 (2002)

A.O. Abdalla, A. Amrin, S. Muhammad, M.A.A. Hanim, Microstructures and hardness of newly designed Ti-6Al-(1–3)Fe alloys. Appl. Mech. Mater. 864, 142–146 (2017)

A.O. Abdalla, A. Amrin, S. Muhammad, M.A.A. Hanim, Iron as a promising alloying element for the cost reduction of titanium alloys. A Review. Appl. Mech. Mater. 864, 147–153 (2017)

Amrin, A. O. Abdalla, M. Toozandehjani, N. Abdul, microstructural transformation by compositional modification of Ti-6Al-4V alloy for aerospace applications. The International Professional Doctoral Symposium (iPDOCs’19), Universiti Teknologi Malaysia, Kuala Lumpur, Malaysia (2019).

A. Bahador, J. Umeda, R. Yamanoglu, A. Amrin, A. Alhazaa, K. Kondoh, Ultrafine-grain formation and improved mechanical properties of novel extruded Ti-Fe-W alloys with complete solid solution of tungsten. J. Alloy. Compound. 875, 160031 (2021)

A. Bahador, A. Issariyapat, J. Umeda, R. Yamanoglu, C. Pruncu, A. Amrin, K. Kondoh, Strength-ductility balance of powder metallurgy Ti–2Fe–2W alloy extruded at high-temperature. J. Mater. Res. Technol. 14, 677–691 (2021)

Q. Chao, P. Cizek, J. Wang, P.D. Hodgson, H. Beladi, Enhanced mechanical response of an ultrafne grained Ti-6Al-4V alloy produced through warm symmetric and asymmetric rolling. Mater. Sci. Eng. A. 650, 404–413 (2016)

Y. Chong, T. Bhattacharjee, J. Yi, S. Zhao, N. Tsuji, Achieving bi-lamellar microstructure with both high tensile strength and large ductility in Ti–6Al–4V alloy by novel thermomechanical processing. Materialia. 8, 100479 (2019)

ASTM E384-17, Standard Test Method for Microindentation Hardness of Materials (ASTM International, West Conshohocken, 2017)

ASTM E8/E8m-13a, Standard Test Methods for Tension Testing of Metallic Materials (ASTM International, West Conshohocken, 2013)

ASTM G102-89, Standard Practice for Calculation of Corrosion Rates and Related Information from Electrochemical Measurements (ASTM International, West Conshohocken, 2010)

A.O. Abdalla, A. Amrin, S. Muhammad, M.A.A. Hanim, Effect of heat treatment parameters on the microstructure and microhardness of Ti-6Al-4V alloy. AIP. Conf. Proc. 1865, 030001 (2017)

R. Jing, S.X. Liang, C.Y. Liu, M.Z. Ma, X.Y. Zhang, R.P. Liu, Structure and mechanical properties of Ti–6Al–4V alloy after zirconium addition. Mater. Sci. Eng. A. 552, 295–300 (2012)

O.M. Ivasishin, R.V. Teliovych, V.G. Ivanchenko, S. Tamirisakandala, D.B. Miracle, Processing, microstructure, texture, and tensile properties of the Ti-6Al-4V-1.55B eutectic alloy. Metallur. Mater. Trans. A. 39, 402–416 (2007)

R. Ding, Z.X. Guo, A. Wilson, Microstructural evolution of a Ti–6Al–4V alloy during thermomechanical processing. Mater. Sci. Eng. A. 327, 233–245 (2002)

D. Banerjee, J.C. Williams, Perspectives on titanium science and technology. Acta. Mater. 61, 844–879 (2013)

M. Motyk, K. Kubiak, J. Sieniawski, and W. Ziaja, Hot plasticity of alpha beta alloys, in: A.K.M. Nurul Amin, Titanium alloys-towards achieving enhanced properties for diversified applications, 87-115. Intech. Open, (2012).

V.A. Joshi, Titanium alloys: an atlas of structures and fracture features (Taylor & Francis, New York, 2006)

T. Seshacharyulu, S.C. Medeiros, W.G. Frazier, Y.V.R.K. Prasad, Microstructural mechanisms during hot working of commercial grade Ti-6Al-4V with lamellar starting structure. Mater. Sci. Eng. A. 325, 112–125 (2002)

C.E. Carlton, P.J. Ferreira, What is behind the inverse Hall-Petch effect in nanocrystalline materials? Acta. Mater. 55, 3749–3756 (2007)

Y.S. Jiménez, M.T. Gil, M.T. Guerra, L. Baltes, J.M. Rosca, Interpretation of open circuit potential of two titanium alloys for a long time immersion in physiological fluid. Bull. Transilvania. Uni. Braşov. 51, 197–204 (2009)

Y. Abdelrhman, M.A.H. Gepreel, S. Kobayashic, S. Okanoc, T. Okamoto, Biocompatibility of new low-cost (α+β)-type Ti-Mo-Fe alloys for long-term implantation. Mater. Sci. Eng. C. 99, 552–562 (2019)

J. Yang, H. Yang, H. Yu, Z. Wang, X. Zeng, Corrosion behavior of additive manufactured Ti-6Al-4V alloy in NaCl solution. Metallur. Mater. Trans. A. 48, 3583–3593 (2017)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Abdalla, A.O., Amrin, A., Jamaludin, K.R. et al. Development of Ti6AlFe Alloy and its Microstructural Transformation During Synthesis and Subsequent Thermo-Mechanical Treatment. Metallogr. Microstruct. Anal. 11, 569–579 (2022). https://doi.org/10.1007/s13632-022-00833-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-022-00833-2