Abstract

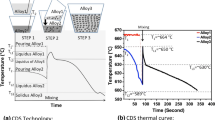

In the present work, first time hardness enhanced due to the precipitation of β″- and β′-phases in the solution treated (S.T)-6082 Al alloy was calculated with the help of empirical relations, and experimentally validated via Vickers’s hardness tester. For this, S.T-6082 Al alloy underwent for the differential scanning calorimetry study at the different heating rate from 5°C/min to 20°C/min. The isochronal heat treatment was performed up to 244°C and 297°C, respectively, at the heating rate of 15°C/min followed by the rapid water quenching for evolving the β″- and β′-phases. The Kissinger plot was drawn to calculate the activation energies required (104 kJ/mol and 110 kJ/mol) for the precipitation of β″- and β′-phases, respectively. Arrhenius relationship (\(ln \Delta HV=\frac{-E}{RT}+ \mathrm{ln}\Delta {HV}_{0}\)) and Kissinger equation ((\(\mathrm{ln}\left(\frac{B}{{T}^{2}}\right)= -\frac{E}{RT}+Constant\) ) were used to calculate the rise in hardness due to the precipitation of β″- (30.7 HV) and β′-phases (18.64 HV), respectively.

Similar content being viewed by others

Data Availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also form part of an ongoing study.

References

P. Nageswara Rao, B. Viswanadh, R. Jayaganthan, Effect of cryorolling and warm rolling on precipitation evolution in Al 6061 alloy. Mater. Sci. Eng. A. 606, 1–10 (2014)

N. Kumar, P. Nageshwara Rao, R. Jayaganthan, H.-G. Brokmeier, Effect of cryorolling and annealing on recovery, recrystallisation, graingrowth and their influence on mechanical and corrosion behaviour of 6082 Al alloy. Mater. Chem. Phys. 165, 177–187 (2015)

A. Abdollahzadeh, B. Bagheri, M. Abassi, A.H. Kokabi, A.O. Moghaddam, Comparison of the weldability of AA6061-T6 joint under different friction stir welding conditions. JMEPEG. 30, 1110–1127 (2021)

N. Kumar, S. Goel, R. Jayaganthan, H.-G. Brokmeier, Effect of solution treatment on mechanical and corrosion behaviors of 6082–T6 Al alloy. Metallogr. Microstruct. Anal. 4, 411–422 (2015)

N. Kumar, G.M. Owolabi, R. Jayaganthan, O.O. Ajide, Plane stress fracture toughness of cryorolled 6082 Al alloy. Theoret. Appl. Fract. Mech. 95, 28–41 (2018)

N. Kumar, K. Singh, A. Singh, Microstructural evolution after heat treatment of high specific strength steel: Fe-13Al-16Mn-5Ni-0.8C and correlation with tensile properties. Materialia. 22, 101412 (2022)

N. Kumar, S. Goel, R. Jayaganthan, G.M. Owolabi, Correlation of fracture toughness with microstructural features for ultrafine grained 6082 Al alloy. Fatigue Fract. Eng. Mater. Struct. 41(9), 1884–1899 (2018)

N. Kumar, S. Goel, R. Jayaganthan, G.M. Owolabi, The influence of metallurgical factors on low cycle fatigue behavior of ultra-fine grained 6082 Al alloy. Int. J. Fatigue. 110, 130–143 (2018)

N. Kumar, R. Jayaganthan, H.G. Brokmeier, Effect of deformation temperature on precipitation, microstructural evolution, mechanical and corrosion behavior of 6082 Al alloy. Trans. Nonferrous Soc. China. 27(3), 475–492 (2017)

W. Sha, Activation energy for precipitation hardening and softening in aluminium alloys calculated using hardness and resistivity data. Phys. Stat. Sol. (A). 203(8), 1927–1933 (2006)

http://www.struers.com/en-GB/Knowledge/Hardness-testing/Vickers#.

Acknowledgement

The author would like to acknowledge the financial support received under the scheme of seed grant provided to Dr. Nikhil Kumar by the IIT (BHU), Varanasi, India.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kumar, N. Hardness Measurement of Al-Mg-Si Alloy: Experimentation and Theoretical Validation. Metallogr. Microstruct. Anal. 11, 467–471 (2022). https://doi.org/10.1007/s13632-022-00865-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-022-00865-8