Abstract

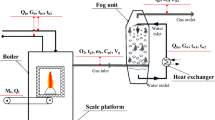

Many treatment technologies exist for particulate matter capture from the flue gas. Heat recovery from flue gases is a significant advantage of scrubber technology, which promotes energy efficiency increase of the combustion unit. The amount of recovered heat depends on heat and mass transfer in the scrubber. This paper presents the investigation of innovative small-scale flue gas treatment technology—fog unit. Households produce significant share of particulate matter in Europe. Therefore, there is a need to provide flue gas treatment technologies for domestic boilers in agreement with EU directive 2009/125/EC. Experimental research was done to identify the performance of proposed technology depending on inlet water flow rate, gas flow rate, water temperature, droplets diameter and water–gas flow ratio. The regression equations were developed based on performed data analysis. Equations can be used to predict the capacity of fog unit, outlet water temperature and outlet gas temperature.

Similar content being viewed by others

Abbreviations

- α :

-

Convective heat transfer coefficient (W/m2 K)

- β p :

-

Mass transfer coefficient (k mol/Ns)

- ω 1, ω 2 :

-

Inlet and outlet moisture content (kg/kg dry gas)

- c pv :

-

Specific heat capacity of vapor (J/kg K)

- d d :

-

Diameter of droplet (m)

- d d0 :

-

Initial diameter of droplet (m)

- d d1 :

-

Manufacturer-defined nozzle diameter (μm)

- d d2 :

-

Droplets diameter during the experiment (μm)

- F d :

-

Droplet surface area (m2)

- G w :

-

Water volumetric flow rate (water volumetric flow rate, l/h)

- g :

-

Water volumetric flow rate (l/s)

- M v :

-

Molecular weight of vapor (kg/k mol)

- n d :

-

Number of drops (s−1)

- Q ht :

-

Convective heat (W)

- Q cg :

-

Gas mass transfer heat (W)

- Q cw :

-

Water mass transfer heat (W)

- Q fu :

-

Fog unit capacity (kW)

- p 1 :

-

Manufacturer-defined pressure in front of the nozzle (bar)

- p 2 :

-

Pressure in front of the nozzle during the experiment (bar)

- p b :

-

Partial pressure of vapor in gas bulk (Pa)

- p sat :

-

Partial pressure at the drop surface (Pa)

- r :

-

Water phase transfer heat (J/kg)

- t g :

-

Gas temperature (°C)

- t g1, t g2 :

-

Inlet and outlet gas temperature (°C)

- t w :

-

Water temperature (°C)

- t w1, t w2 :

-

Inlet and outlet water temperature (°C)

- t s :

-

Vapor condensation temperature on the surface of droplets (°C)

- V g :

-

Gas volumetric flow rate (m3/s)

- V w :

-

Water volumetric flow rate (m3/s)

References

Directive 2009/125/EC of the European Parliament and of the Council of 21 October 2009 establishing a framework for the setting of ecodesign requirements

Vinnichenko, N.A., Uvarov, A.V., Plaksina, Y.Y.: Combined study of heat exchange near the liquid–gas interface by means of background oriented schlieren and infrared thermal imaging. Exp. Therm. Fluid Sci. 59, 238–245 (2014). https://doi.org/10.1016/j.expthermflusci.2013.11.023

Triebe R.: Condensing heat recovery for industrial process applications. Process Heating (2015). https://www.thermalenergy.com/uploads/9/4/5/9/9459901/condensing_heat_recovery_for_industrial_process_applications.pdf

Li, H.-W., Wu, K.-B., Wang, S.-B.: Numerical simulation of the influence of flue gas discharge patterns on a natural draft wet cooling tower with flue gas injection. Appl. Therm. Eng. 161, 114137 (2019). https://doi.org/10.1016/j.applthermaleng.2019.114137

Li, H.-W., Duan, W.-B., Wang, S.-B., Zhang, X.-L., Sun, B., Hong, W.-P.: Numerical simulation study on different spray rates of three-area water distribution in wet cooling tower of fossil-fuel power station. Appl. Therm. Eng. 130, 1558–1567 (2018). https://doi.org/10.1016/j.applthermaleng.2017.11.107

Zunaid, M., Murtaza, Q., Gautam, S.: Energy and performance analysis of multi droplets shower cooling tower at different inlet water temperature for air cooling application. Appl. Therm. Eng. 121, 1070–1079 (2017). https://doi.org/10.1016/j.applthermaleng.2017.04.157

Bo, Y., Yi, J., Lin, F., Shigang, Z.: Experimental and theoretical investigation of a novel full-open absorption heat pump applied to district heating by recovering waste heat of flue gas. Energy Build. 173, 45–57 (2018). https://doi.org/10.1016/j.enbuild.2018.05.021

Cui, L., Song, X., Li, Y., Wang, Y., Feng, Y., Yan, L., Dong, Y.: Synergistic capture of fine particles in wet flue gas through cooling and condensation. Appl. Energy 225, 656–667 (2018). https://doi.org/10.1016/j.apenergy.2018.04.084

Macedonio, F., Brunetti, A., Barbieri, G., Drioli, E.: Membrane condenser configurations for water recovery from waste gases. Sep. Purif. Technol. 181, 60–68 (2017). https://doi.org/10.1016/j.seppur.2017.03.009

Yang, B., Shen, G., Chen, H., Feng, Y., Wang, L.: Experimental study of condensation heat-transfer and water-recovery process in a micro-porous ceramic membrane tube bundle. Appl. Therm. Eng. 155, 354–364 (2019). https://doi.org/10.1016/j.applthermaleng.2019.03.154

Hebenstreit, B., Schnetzinger, R., Ohnmacht, R., Höftbergera, E., Lundgren, J., Haslinger, W., Toffolo, A.: Techno-economic study of a heat pump enhanced flue gas heat recovery for biomass boilers. Biomass Bioenergy 71, 12–22 (2014). https://doi.org/10.1016/j.biombioe.2014.01.048

Fedorova, N., Aziziyanesfahani, P., Jovicic, V., Rasic-Zbogar, A., Khan, M.J., Delgado, A.: Investigation of the concepts to increase the dew point temperature for thermal energy recovery from flue gas, using aspen. Energies 12(9), 1585 (2019). https://doi.org/10.3390/en12091585

Coppieters, T., Blondeau, J.: Techno-economic design of flue gas condensers for medium-scale biomass combustion plants: impact of heat demand and return temperature variations. Energies (2019). https://doi.org/10.3390/en12122337

Terhan, M., Comakli, K.: Design and economic analysis of a flue gas condenser to recover latent heat from exhaust flue gas. Appl. Therm. Eng. 100, 1007–1015 (2016). https://doi.org/10.1016/j.applthermaleng.2015.12.122

Roberts, P., Luther Els, C.J., Bosyi, O., Kornelius, G.: The economics of flue gas cooling technology for coal-fired power stations with flue gas desulfurisation. Clean Air J. (2018). https://doi.org/10.17159/2410-972x/2018/v28n1a8

Valle-Zermeño, R.D., Formosa, J., Aparicio, J.A., Guembe, M., Chimenos, J.M.: Transposition of wet flue gas desulfurization using MgO by-products: from laboratory discontinuous batch reactor to pilot scrubber. Fuel Process. Technol. 138, 30–36 (2015). https://doi.org/10.1016/j.fuproc.2015.05.002

Koralegedara, N.H., Pinto, P.X., Dionysiou, D.D., Al-Abed, S.R.: Recent advances in flue gas desulfurization gypsum processes and applications—a review. J. Environ. Manag. 251, 109572 (2019). https://doi.org/10.1016/j.jenvman.2019.109572

Gómez, A., Fueyoa, N., Tomás, A.: Detailed modelling of a flue-gas desulfurisation plant. Comput. Chem. Eng. 31(11), 1419–1431 (2007). https://doi.org/10.1016/j.compchemeng.2006.12.004

Krakowiak, S., Darowicki, K.: Degradation of protective coatings in steel stacks of flue gas desulfurisation systems. Prog. Org. Coat. 117, 141–145 (2018). https://doi.org/10.1016/j.porgcoat.2018.01.011

Zhao, B., Liu, F., Cui, Z., Liu, C., Yue, H., Tang, S., Liu, Y., Lu, H., Liang, B.: Enhancing the energetic efficiency of MDEA/PZ-based CO2 capture technology for a 650 MW power plant: process improvement. Appl. Energy 185, 362–375 (2017). https://doi.org/10.1016/j.apenergy.2016.11.009

Wu, X.M., Qin, Z., Yu, Y.S., Zhang, Z.X.: Experimental and numerical study on CO2 absorption mass transfer enhancement for a diameter-varying spray tower. Appl. Energy 225, 367–379 (2018). https://doi.org/10.1016/j.apenergy.2018.04.053

Zhang, X., Li, Z.: A liquid-desiccant-based heat recovery system for gas-fired boilers in district heating networks. ASHRAE Trans. 125(1), 410–417 (2019)

Ding, T., Sun, B., Shi, Z., Li, B.: Optimizing water droplet diameter of spray cooling for dairy cow in summer based on enthalpy. Energies 12(19), 3637 (2019). https://doi.org/10.3390/en12193637

Wang, H., Xiao, Q., Xu, J.: Direct-contact heat exchanger. In: Heat Exchangers-Design, Experiment and Simulation. InTech (2016). http://dx.doi.org/10.5772/66630

Zhu, J., Ye, S.-C., Bai, J., Wu, Z.-Y., Liu, Z.-H., Yang, Y.-F.: A concise algorithm for calculating absorption height in spray tower for wet limestone-gypsum flue gas desulfurization. Fuel Process. Technol. 129, 15–23 (2015). https://doi.org/10.1016/j.fuproc.2014.07.002

Kallinikos, L.E., Farsari, E.I., Spartinos, D.N., Papayannakos, N.G.: Simulation of the operation of an industrial wet flue gas desulfurization system. Fuel Process. Technol. 91, 1794–1802 (2010). https://doi.org/10.1016/j.fuproc.2010.07.020

Demidovich, A.V., Kralinova, S.S., Tkachenko, P.P., Shlegel, N.E., Volkov, R.S.: Interaction of liquid droplets in gas and vapor flows. Energies 12(22), 4256 (2019). https://doi.org/10.3390/en12224256

Nishad, K., Sadiki, A., Janicka, J.: Numerical investigation of AdBlue droplet evaporation and thermal decomposition in the context of NOx-SCR using a multi-component evaporation model. Energies 11(1), 222 (2018). https://doi.org/10.3390/en11010222

Teodori, E., Pontes, P., Moita, A., Georgoulas, A., Marengo, M., Moreira, A.: Sensible heat transfer during droplet cooling: experimental and numerical analysis. Energies 10(6), 790 (2017). https://doi.org/10.3390/en10060790

Holz, S., Braun, S., Chaussonnet, G., Koch, R.: Close nozzle spray characteristics of a prefilming airblast atomizer. Energies 12(14), 2835 (2019). https://doi.org/10.3390/en12142835

Sun, Y., Guan, Z., Gurgenci, H., Hooman, K., Li, X.: Investigations on the influence of nozzle arrangement on the pre-cooling effect for the natural draft dry cooling tower. Appl. Therm. Eng. 130, 979–996 (2018). https://doi.org/10.1016/j.applthermaleng.2017.10.171

Yang, J., Zhao, Y., Chen, A., Quan, Z.: Thermal performance of a low-temperature heat exchanger using a micro heat pipe array. Energies 12(4), 675 (2019). https://doi.org/10.3390/en12040675

Veidenbergs, I.: District heating return temperature influence on the flue gas condenser capacity. In: Riga Technical University 53rd International Scientific Conference Dedicated to the 150th Anniversary and the 1st Congress of World Engineers and Riga Polytechnical Institute (2012)

Ochowiak, M., Broniarz-Press, L.: The flow resistance and aeration in modified spray tower. Chem. Eng. Process. 50, 345–350 (2011). https://doi.org/10.1016/j.cep.2011.01.009

Natale, F.D., Motta, F.L., Carotenuto, C., Tammaro, M., Lancia, A.: Condensational growth assisted Venturi scrubber for soot particles emissions control. Fuel Process. Technol. 175, 76–89 (2018). https://doi.org/10.1016/j.fuproc.2018.01.018

Miliauskas, G., Maziukienė, M., Puida, E.: Modelling of heat and mass transfer processes in phase transformation cycle of sprayed water into gas: 5. Numerical modelling optimization of phase transformation cycle for droplets slipping in gas flow. Mech. Fluids Gas. (2017). https://doi.org/10.5755/j01.mech.23.1.13689

Xiao, Q., Yang, K., Wu, M., Pan, J., Xu, J., Wang, H.: Complexity evolution quantification of bubble pattern in a gas-liquid mixing system for direct-contact heat transfer. Appl. Therm. Eng. 138, 832–839 (2018). https://doi.org/10.1016/j.applthermaleng.2018.04.058

Li, H., Tian, M., Tang, L.: Axisymmetric numerical investigation on steam bubble condensation. Energies 12(19), 3757 (2019). https://doi.org/10.3390/en12193757

Grosshans, H.: Evaporation of a droplet. Project Report. MVK160 Heat and Mass Transport (2012)

Monteith, M.H.: Principles of Environmental Physics, vol. 4, p. 403. Elsevier, Amsterdam (2013)

Priedniece, V., Kirsanovs, V., Dzikevics, M., Vigants, G., Veidenbergs, I., Blumberga, D.: Laboratory research of the flue gas condenser—fog unit. Energy Proc. 147, 482–487 (2018). https://doi.org/10.1016/j.egypro.2018.07.056

Priedniece, V., Kalnins, E., Kirsanovs, V., Dzikevics, M., Blumberga, D., Veidenbergs, I.: Sprayed water flowrate, temperature and drop size effects on small capacity flue gas condenser’s performance. Environ. Clim. Technol. 23(3), 333–346 (2019). https://doi.org/10.2478/rtuect-2019-0099

Acknowledgement

The work has been supported by European Regional Development Fund project “Individual Heating with Integrated Fog Unit System (IFUS)” 1.1.1.1/16/A/015.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Blumberga, D., Priedniece, V., Kalniņš, E. et al. Innovative scrubber technology model for domestic boiler application. Int J Energy Environ Eng 12, 11–21 (2021). https://doi.org/10.1007/s40095-020-00347-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40095-020-00347-z