Abstract

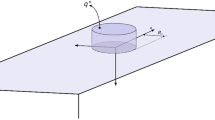

The use of narrow gap for thick component welding as applied in nuclear industries and especially by AREVA NP, requires the mastering of several parameters and especially shrinkage. The prediction through to numerical simulation is very helpful for welding procedure definition. This paper describes an approach used to determine a 3D heat source dedicated to a new industrial welding process configuration (deep narrow groove multipass low-carbon steel gas metal arc (GMA) welding, two passes per layer) to assess the groove shrinkage which occurs during welding by numerical simulation. Parameters of this 3D heat source are identified by solving an inverse heat conduction problem by a least square method. A multiobjective optimization is performed with a new proposed metric (Hausdorff distance) in the objective function (sum of square) in order to simulate relevant bead shape and temperatures in the solid zone. Finally, the identified 3D heat source model is a combination of two volumetric heat sources containing five parameters each. It can be used as thermal loading for subsequent thermal metallurgical mechanical calculations.

Similar content being viewed by others

References

Goldak JA, Chakravarti A, Bibby M (1984) A new finite element model for welding heat source. Metall Trans B 15B:299–305

Emery AF, Nenarokomov AV (1998) Optimal experiment design. Meas Sci Technol 9(6):864

Beck JV, Arnold KJ (1977) Parameter estimation in engineering and science. Wiley, New York

Asserin O (2009) Methodology for heat source parameters identification in the frame of computational weld mechanic. Implementation with the software WPROCESS. Technical report DEN/DANS/DM2S/SEMT/LTA/09-003/A, CEA

Wang HX, Sun JS, Wei YH, Zheng YY (2005) Simulation of GMAW thermal process based on string heat source model. Sci Technol Weld Join 10(5):511–520

Nagesh D, Datta G (2008) Modeling of fillet welded joint of GMAW process: integrated approach using doe, ann and ga. Int J Interact Des Manuf (IJIDeM) 2(3):127–136

Hu J, Tsai HL (2008) Modelling of transport phenomena in 3D GMAW of thick metals with V groove. J Phys D Appl Phys 41(6):065202

Schnick M, Fuessel U, Hertel M, Haessler M, Spille-Kohoff A, Murphy AB (2010) Modelling of gas-metal arc welding taking into account metal vapour. J Phys D Appl Phys 43(43):434008

Roatta JL (2004) Heat source modelling for the accurate simulation of the temperature field in a 316L narrow gap multi-pass arc welding. Master Thesis, University of Nantes

Gabriel F, Ayrault D, Fontes A, Roatta JL, Raynaud M (2007) Global method for estimation of heat source parameters dedicated to narrow gap GTA welding. In: Cerjak H, Bhadeshia HKD, Kozeschnik E (eds) Mathematical modeling of weld phenomena, vol 8. TU Graz, Verlag der Technischen Universität Graz, Graz, pp 25–27

Azar AS, Ås SK, Akselsen OM (2012) Determination of welding heat source parameters from actual bead shape. Comput Mater Sci 54(0):176–182

Özişik MN, Orlande HRB (2000) Inverse heat transfer: a fundamentals and applications. Taylor & Francis, New York

Kumar A, DebRoy T (2004) Guaranteed fillet weld geometry from heat transfer model and multivariable optimization. Int J Heat Mass Transfer 47(26):5793–5806

Huttenlocher DP, Klanderman GA, Rucklidge WJ (1993) Comparing images using the Hausdorff distance. IEEE Trans Pattern Anal Mach Intell 15:850–863

Nocedal J (1980) Updating quasi-Newton matrices with limited storage. Math Comput 35:773–781

Asserin O, Ayrault D (2011) Heat source identification for narrow gap gaz metal arc welding. Technical report DEN/DANS/DM2S/SEMT/LTA/11-014/A, CEA

Lindgren LE (2007) Computational welding mechanics: thermomechanical and microstructural simulations. Woodhead Publishing in Materials, Cambridge

Lundbäck A, Alberg H, Henriksson P (2005) Simulation and validation of TIG welding and post weld heat treatment of an Inconel 718 plate. In: Cerjak H et al (eds) Mathematical modelling of weld phenomena, vol 7. Technischen Universität Graz, Verlag der Technischen Universität Graz, Graz, pp 683–696

De A, DebRoy T (2004) Probing unknown welding parameters from convective heat transfer calculation and multivariable optimization. J Phys D Appl Phys 37(1):140

Author information

Authors and Affiliations

Corresponding author

Additional information

Doc. IIW-2425, recommended for publication by Commission XII “Arc Welding Processes and Production Systems”.

Rights and permissions

About this article

Cite this article

Asserin, O., Ayrault, D., Gilles, P. et al. Identification of a heat source model for multipass narrow groove GMA welding process. Weld World 58, 161–169 (2014). https://doi.org/10.1007/s40194-013-0109-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-013-0109-4