Abstract

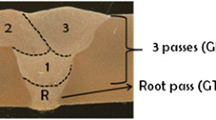

The influence of shielding gases on welding performance and on properties of duplex and superduplex stainless steel welds was studied. Using argon as the reference gas, helium, nitrogen and carbon dioxide were added and five mixtures evaluated. Bead-on-plate welds and circumferential pipe welds were produced using mechanised GMA welding in the downhand position. Welding performance, corrosion resistance, mechanical properties, microstructural features and weld imperfections were assessed and related to the shielding gas. Shielding gases containing 30 % helium showed excellent results; whilst pure argon showed unstable arc and poor weld pool fluidity and Ar + 2 %CO2 resulted in underfill and porosity. Mixtures containing helium resulted in higher ductility welds and higher impact toughness values than welds produced with Ar + 2 %CO2. Sound and balanced duplex microstructures free from intermetallics were found with suitable ferrite contents for all the shielding gases studied. All the duplex pipe welds passed the corrosion test regardless of the shielding gas used, and the best results in the corrosion test for superduplex pipe welds were found when using Ar + 30 %He + 0.5 %CO2 + 1.8 %N2 as shielding gas.

Similar content being viewed by others

References

Karlsson L (2012) Welding duplex stainless steels—a current review of recommendations. Weld World 56:65–76

van Nassau L, Meelker H, Hilkes J (1993) Welding duplex and super-duplex stainless steels. Weld World 31(5):322–343

Lu S, Fujii H, Nogi K (2010) Weld shape variation and electrode oxidation behavior under Ar-(Ar-CO2) double shielded GTA welding. J Mat Sci Technol 26(2):170–176

Pettersson C-O, Fager S-Å (1995) Welding practice for the Sandvik duplex stainless steels SAF 2304, SAF 2205 and SAF 2507. AB Sandvik Steel. Technical document S-91-57, 15

Westin EM, Johansson MM, Bylund L-Å, Pettersson RFA (2013) Effect on microstructure and properties of superduplex stainless steel welds when using backing gas containing nitrogen and hydrogen. IIW Commission IX Document IX-2459-13 rev.1. 9

EN ISO 6947:2011 (2011) Welding and allied processes—welding positions

How to weld duplex stainless steels (2006) Avesta Welding AB. Document 10601EN-GB, Avesta, Sweden, 20

Welding guidelines for duplex & superduplex stainless steels (2005) Metrode Products Limited. Chertsey, UK, 7

Fuji H, Lu S, Sato T, Nogi K (2008) Effect of oxygen content in He-O2 shielding gas on weld shape for ultra deep penetration TIG. Trans Jpn Weld Res Inst 37(1):19–26

Persson K-A (2014) Pore formation in MIG welding duplex stainless steels with super duplex filler wire. Conference “Svetsning av rostfria stål” organised by Swerea/Kimab. Stockholm

EN 10028: 2008 (2008) Flat products made of steels for pressure purposes, part 7: stainless steels

NORSOK STANDARD M-601 (2008) Welding and inspection of piping

Welding consumables technical handbook (2009) Metrode Products Limited. Revision 10, Chertsey, UK, 384

Vitek JM, Iskander YS, Oblow EM (2000) Improved ferrite number prediction in stainless steel arc welds using artificial neural networks—part 2: neural network results. Weld J 79(2):41s–50s

Kotecki DJ, Siewert TA (1992) WRC-1992 constitution diagram for stainless steel weld metals: a modification of the WRC-1988 diagram. Weld J 71(5):171s–178s

Valiente-Bermejo MA (2012) A mathematical model to predict δ-ferrite content in austenitic stainless steel weld metals. Weld World 56(09–10):48–68

Acknowledgments

The Knowledge Foundation is gratefully acknowledged for the economic funding. The great support received from the business partners involved: AGA Gas AB, ESAB AB and Sandvik Materials Technology and the involvement and contribution of their representatives are also acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Doc. IIW-2511, recommended for publication by Commission IX “Behaviour of Metals Subjected to Welding.”

Rights and permissions

About this article

Cite this article

Valiente Bermejo, M., Karlsson, L., Svensson, LE. et al. Effect of shielding gas on welding performance and properties of duplex and superduplex stainless steel welds. Weld World 59, 239–249 (2015). https://doi.org/10.1007/s40194-014-0199-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-014-0199-7