Abstract

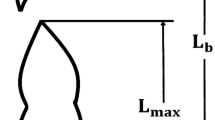

In this work, a detailed investigation on the effects of particle diameter on the fluidization characteristics of gas–particle flows inside a bubbling gas–solid fluidized bed has been carried out. The studies are performed using an in-house flow solver developed employing the Eulerian–Eulerian two-fluid model. Simulations carried out using the solver indicate that particle diameter has significant effects on the overall flow hydrodynamics inside a bubbling gas–solid fluidized bed. Numerical evidence suggests that time-averaged particle velocity at any section inside the fluidization zone decreases, while the time-averaged particle volume fraction increases with an increase in particle diameter. For a given diameter, the magnitude of maximum time-averaged particle velocity at any section has been found to increase gradually inside the fluidization zone as we move toward the outlet. Interestingly, this variation in the time-averaged particle velocity with height becomes less prominent with the increase in particle diameter.

Similar content being viewed by others

References

Loha C, Chattopadhyay H, Chatterjee P (2012) Assessment of drag models in simulating bubbling fluidized bed hydrodynamics. Chem Eng Sci 75:400–407

van Wachem BGM, Schouten JC, van der Bleek CM (2001) Comparative analysis of CFD models of dense gas–solid systems. AIChE J 47(5):1035–1050

Taghipour F, Ellis N, Wong C (2005) Experimental and computational study of gas–solid fluidized bed hydrodynamics. Chem Eng Sci 60:6857–6867

Passalacqua A, Marmo L (2009) A critical comparison of frictional stress models applied to the simulation of bubbling fluidized beds. Chem Eng Sci 160:2795–2806

Lindborg H, Lysberg M, Jakobsen H (2007) Practical validation of the two-fluid model applied to dense gas–solid flows in fluidized beds. Chem Eng Sci 62:5854–5869

Benyahia S, Syamlal M, O’Brien T (2007) Study of the ability of multiphase continuum models to predict core-annulus flow. AIChE J 53:2549–2568

Loha C, Chattopadhyay H, Chatterjee P (2013) Euler–Euler CFD modeling of fluidized bed: influence of specularity coefficient on hydrodynamic behavior. Particuology 11:673–680

Loha C, Chattopadhyay H, Chatterjee P (2014) Effect of coefficient of restitution in Euler–Euler CFD simulation of fluidized-bed hydrodynamics. Particuology 15:170–177

Verma V, Padding JT, Deen NG, Kuipers JAM (2015) Effect of bed size on hydrodynamics in 3-D gas–solid fluidized beds. AIChE J 61(5):1492–1506

Zinani F, Philippsen C, Indrusiak M (2016) Numerical study of gas–solid drag models in a bubbling fluidized bed. Part Sci Technol 36(1):1–10

Geldart D (1973) Types of gas fluidization. Powder Technol 7(5):285–292

Kotoky S, Dalal A, Natarajan G (2018) A parametric study of dispersed laminar gas-particle flows through vertical and horizontal channels. Adv Powder Technol 29(5):1072–1084

Kotoky S, Dalal A, Natarajan G (2018) Effects of specularity and particle–particle restitution coefficients on the hydrodynamic behavior of dispersed gas-particle flows through horizontal channels. Adv Powder Technol 29(4):874–889

Kotoky S, Dalal A, Natarajan G (2018) Effects of specularity and particle–particle restitution coefficients on the recirculation characteristics of dispersed gas-particle flows through a sudden expansion. Adv Powder Technol 29(10):2463–2475

Gidaspow D (1994) Multiphase flow and fluidization: continuum and kinetic theory descriptions. Academy Press, New York

Liu Y, Hinrichsen O (2014) CFD modeling of bubbling fluidized beds using openFOAM: model validation and comparison of TVD differencing schemes. Comput Chem Eng 75:19–50

Schaeffer DG (1987) Instability in the evolution equations describing incompressible granular flow. J Differ Equ 66:19–50

Johnson P, Jackson R (1987) Frictional-collisional constitutive relations for granular materials, with application to plane shearing. J Fluid Mech 176:67–93

Lun C, Savage S, Chepurning N (1984) Kinetic theories for granular flow: inelastic particles in Couette flow and singly inelastic particles in a general flow field. J Fluid Mech 140:223–237

Sinclair JL, Jackson R (1989) Gas-particle flow in vertical pipe with particle-particle interactions. AIChE J 35:1473–1481

Moukalled F, Darwish M, Sekar B (2003) A pressure-based algorithm for multi-phase flow at all speeds. J Comput Phys 190:550–571

Rhie CM, Chow WL (1983) Numerical study of the turbulent flow past an airfoil with trailing edge separation. AIAA J 21:1525–1532

Spalding DB (1980) Numerical computation of multi-phase fluid flow and heat transfer. Recent Adv Numer Methods Fluids 1:139–167

LIS, Library of Iterative Solvers for Linear Systems, LIS user guide. www.ssisc.org/lis

Gelderbloom S, Gidaspow D, Lyczkowski R (2003) CFD simulations of bubbling/collapsing fluidized beds for three Geldart groups. AIChE J 49:844–858

Jung JH, Yoon HS, Lee CY, Shin SC (2012) Effect of the vertical baffle height on the liquid sloshing in a three-dimensional rectangular tank. Ocean Eng 44:79–89

Passalacqua A, Fox RO (2011) Implementation of an iterative solution procedure for multi-fluid gas-particle flow models on unstructured grids. Powder Technol 213:174–187

Funding

This study is funded by a grant from DAE-BRNS, Govt. of India.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest Statement

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kotoky, S., Dalal, A. & Natarajan, G. A computational analysis of the role of particle diameter on the fluidization behavior in a bubbling gas–solid fluidized bed. Comp. Part. Mech. 7, 555–565 (2020). https://doi.org/10.1007/s40571-019-00279-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40571-019-00279-4