Abstract

Particle size distribution (PSD) is an important characteristic of many materials. Increasingly, this characteristic is determined using the laser diffraction method (LDM). Theoretical assumptions of LDM are, i.a. the spherical shape of the measured particles and their random orientation. These criteria are often not met. 3D prints were used to test the impact of shape on LDM PSD and to monitor particle flow with high-speed camera. It can be noticed that when the shape of the examined particles differs from a spherical shape, PSDs obtained with the use of LDM are burdened with an error that is difficult to estimate. Moreover, the more the aspect ratio value deviates from unity, the more the distribution shifts towards larger particles. It was noticed that in the case of cylinders there were no particle rotations in about 70% of cases. A lack of rotation was also observed for hemispheres—in about 16% of cases. Minimization of the errors resulting from the influence of the shape (and the related lack of rotation) of the measured particles on the obtained results may be achieved by designing the measuring cell of the diffractometer in such a way that rotation would be forced.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Guner G, Kannan M, Berrios M, Bilgili E (2021) Use of bead mixtures as a novel process optimization approach to nanomilling of drug suspensions. Pharm Res 38:1279–1296. https://doi.org/10.1007/s11095-021-03064-2

Calvez I, Szczepanski CR, Landry V (2021) Preparation and characterization of low gloss UV-curable coatings based on silica surface modification using an acrylate monomer. Prog Org Coat 158:106369. https://doi.org/10.1016/j.porgcoat.2021.106369

Gan C, Luo W, Yu Y, Jiao Z, Li S, Su D, Feng J, Zhao X, Qiu Y, Hu L, Zhou D, Xiong X, Wang J, Yang H (2021) Intratracheal inoculation of AHc vaccine induces protection against aerosolized botulinum neurotoxin A challenge in mice. Npj Vaccines 6:87. https://doi.org/10.1038/s41541-021-00349-w

Makó A, Szabó B, Rajkai K, Szabó J, Bakacsi Z, Labancz V, Hernádi H, Barna G (2019) Evaluation of soil texture determination using soil fraction data resulting from laser diffraction method. Int Agrophys 33:445–454. https://doi.org/10.31545/intagr/113347

Stojanovska Pecova M, Geskovski N, Petrushevski G, Makreski P (2021) A novel method for rapid particle size analyzis of ibuprofen using near-infrared spectroscopy. AAPS PharmSciTech 22:268. https://doi.org/10.1208/s12249-021-02156-x

Pan L, Ge B, Zhang F (2017) Indetermination of particle sizing by laser diffraction in the anomalous size ranges. J Quant Spectrosc Radiat Transf 199:20–25. https://doi.org/10.1016/j.jqsrt.2017.05.022

Bieganowski A, Ryżak M, Sochan A, Barna G, Hernádi H, Beczek M, Polakowski C, Makó A (2018) Laser diffractometry in the measurements of soil and sediment particle size distribution. In: Advances in agronomy. pp 215–279. https://doi.org/10.1016/bs.agron.2018.04.003.

Pabst W, Berthold C, Gregorova E (2006) Size and shape characterization of polydisperse short-fiber systems. J Eur Ceram Soc 26:1121–1130. https://doi.org/10.1016/j.jeurceramsoc.2005.01.053

Kelly RN, Kazanjian J (2006) Commerical reference shape standards use in the study of particle shape effect on laser diffraction particle size analyzis. AAPS PharmSciTech 7:E126–E137. https://doi.org/10.1208/pt070249

Xu R, Di Guida OA (2003) Comparison of sizing small particles using different technologies. Powder Technol 132:145–153. https://doi.org/10.1016/S0032-5910(03)00048-2

Dur JC, Elsass F, Chaplain V, Tessier D (2004) The relationship between particle-size distribution by laser granulometry and image analyzis by transmission electron microscopy in a soil clay fraction. Eur J Soil Sci 55:265–270. https://doi.org/10.1111/j.1365-2389.2004.00597.x

Campbell JR (2003) Limitations in the laser particle sizing of soils. In: Roach IC (ed) Advances in Regolith, CRC LEME. pp 38–42

Polakowski C, Sochan A, Bieganowski A, Ryzak M, Földényi R, Tóth J (2014) Influence of the sand particle shape on particle size distribution measured by laser diffraction method. Int Agrophys 28:195–200. https://doi.org/10.2478/intag-20014-0008

Gabas N, Hiquily N, Laguérie C (1994) Response of laser diffraction particle sizer to anisometric particles. Part Part Syst Charact 11:121–126. https://doi.org/10.1002/ppsc.19940110203

Polakowski C, Ryżak M, Bieganowski A, Sochan A, Bartmiński P, Dębicki R, Stelmach W (2015) The reasons for incorrect measurements of the mass fraction ratios of fine and coarse material by laser diffraction. Soil Sci Soc Am J 79:30–36. https://doi.org/10.2136/sssaj2013.07.0286

Mühlenweg H, Hirleman ED (1998) Laser diffraction spectroscopy: influence of particle shape and a shape adaptation technique. Part Part Syst Charact 15:163–169. https://doi.org/10.1002/(SICI)1521-4117(199808)15:4%3c163::AID-PPSC163%3e3.0.CO;2-8

Tinke AP, Carnicer A, Govoreanu R, Scheltjens G, Lauwerysen L et al (2008) Particle shape and orientation in laser diffraction and static image analyzis size distribution analyzis of micrometer sized rectangular particles. Powder Technol 186:154–167. https://doi.org/10.1016/j.powtec.2007.11.017

Naito M, Hayakawa O, Nakahira K, Mori H, Tsubaki J (1998) Effect of particle shape on the particle size distribution measured with commercial equipment. Powder Technol 100:52–60. https://doi.org/10.1016/S0032-5910(98)00052-7

Berthold C, Klein R, Lühmann J, Nickel KG (2000) Characterization of fibres and fibre collectives with common laser diffractometers. Part Part Syst Charact 17:113–116

Dolenc A, Govedarica B, Dreu R, Kocbek P, Srcic S et al (2010) Nanosized particles of orlistat with enhanced in vitro dissolution rate and lipase inhibition. Int J Pharm 396(1–2):149–155. https://doi.org/10.1016/j.ijpharm.2010.06.003

Heffels CMG, Verheijen PJT, Heitzmann D, Scarlett B (1996) Correction of the effect of particle shape on the size distribution measured with a laser diffraction instrument. Part Part Syst Charact 13:271–279. https://doi.org/10.1002/ppsc.19960130504

Pieri L, Bittelli M, Pisa PR (2006) Laser diffraction, transmission electron microscopy and image analyzis to evaluate a bimodal Gaussian model for particle size distribution in soils. Geoderma 135:118–132. https://doi.org/10.1016/j.geoderma.2005.11.009

Konert M, Vandenberghe J (1997) Comparison of laser grain size analyzis with pipette and sieve analyzis: a solution for the underestimation of the clay fraction. Sedimentology 44:523–535. https://doi.org/10.1046/j.1365-3091.1997.d01-38.x

International Organization for Standardization, ISO 13320:2020 Particle size analyzis—Laser diffraction methods. International Organization for Standarisation, Geneva, Switzerland (2020)

Bowen P, Sheng J, Jongen N (2002) Particle size distribution measurement of anisotropic—particles cylinders and platelets—practical examples. Powder Technol 128:256–261. https://doi.org/10.1016/S0032-5910(02)00182-1

Pabst W, Mikač J, Gregorová E, Havrda J (2002) An estimate of orientation effects on the results of size distribution measurements for oblate particles. Ceram Silikáty 46:41–48

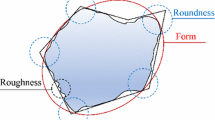

Sochan A, Zieliński P, Bieganowski A (2015) Selection of shape parameters that differentiate sand grains, based on the automatic analyzis of two-dimensional images. Sed Geol 327:14–20. https://doi.org/10.1016/j.sedgeo.2015.07.007

Acknowledgements

The study was financed by the National Science Centre, Poland [2019/03/X/ST10/00330].

Author information

Authors and Affiliations

Contributions

Conceptualisation was contributed by Cezary Polakowski and Andrzej Bieganowski; validation was contributed by Cezary Polakowski, Rafał Mazur, and Michał Beczek; formal analysis was contributed by Cezary Polakowski, Magdalena Ryżak and A.S.; investigation was contributed by Cezary Polakowski, Michał Beczek, Rafał Mazur; resources were contributed by Magdalena Ryżak; writing—original draft preparation, was contributed by Cezary Polakowski; writing—review and editing, was contributed by Cezary Polakowski, Magdalena Ryżak, A.S., Michał Beczek, Rafał Mazur, and Andrzej Bieganowski; visualisation was contributed by Cezary Polakowski; supervision was contributed by Andrzej Bieganowski; funding acquisition was contributed by Cezary Polakowski. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Polakowski, C., Ryżak, M., Sochan, A. et al. The use of 3D prints to assess the influence of shape on particle size distribution in the laser diffraction method. Comp. Part. Mech. 10, 241–248 (2023). https://doi.org/10.1007/s40571-022-00489-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40571-022-00489-3