Abstract

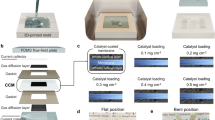

This article reports on a flexible polymer electrolyte membrane fuel cell (PEMFC) with a pre-bent flow field. The performances in the flat and bent positions were lower and higher, respectively than that of the traditional flexible fuel cells. The low performance in the flat position was attributed to the void space induced incomplete contact at the interface of the membrane electrode assembly (MEA) and flow-field plates, which resulted in poor performance due to the high ohmic resistance (5.85 Ω cm2) and faradaic resistance (4.17 Ω cm2). However, when bending stress was applied to the MEA, a decreased ohmic resistance (0.954 Ω cm2), faradaic resistance (0.737 Ω cm2), and an enhanced power density (88.7 mW/cm2) were observed because of the improved interfacial contact property between the MEA and the flow-field plates from the increased compressive stress. These experimental results were further analyzed and visualized with aid of the finite element analysis. Despite the relatively low performance in the flat shape, the proposed pre-bent design of the flexible PEMFC possesses promising applicability especially in flexible electronics where the curved shapes are highly required.

Similar content being viewed by others

References

Lee, J., Yim, C., Lee, D. W., & Park, S. S. (2017). Manufacturing and characterization of physically modified aluminum anodes based air battery with electrolyte circulation. International Journal of Precision Engineering and Manufacturing Green Technology. https://doi.org/10.1007/s40684-017-0007-0.

Shin, D. Y., Yoo, S. S., & Seo, J. Y. (2015). Uncertainty analysis in contact resistivity measurements of crystalline silicon solar cells. International Journal of Precision Engineering and Manufacturing Green Technology. https://doi.org/10.1007/s40684-015-0028-5.

Petri, R., Giebel, T., Zhang, B., Schünemann, J. H., & Herrmann, C. (2016). Material cost model for innovative li-ion battery cells in electric vehicle applications. International Journal of Precision Engineering and Manufacturing Green Technology. https://doi.org/10.1007/s40684-015-0031-x.

Ahn, D. G. (2016). Direct metal additive manufacturing processes and their sustainable applications for green technology: A review. International Journal of Precision Engineering and Manufacturing Green Technology. https://doi.org/10.1007/s40684-016-0048-9.

Lee, H. (2017). Environmental impact of concentration of slurry components in thick copper CMP. International Journal of Precision Engineering and Manufacturing Green Technology. https://doi.org/10.1007/s40684-017-0002-5.

Saravanakumar, B., Mohan, R., Thiyagarajan, K., & Kim, S. J. (2013). Fabrication of a ZnO nanogenerator for eco-friendly biomechanical energy harvesting. RSC Advances. https://doi.org/10.1039/c3ra40447a.

Pu, N. W., Shi, G. N., Liu, Y. M., Sun, X., Chang, J. K., Sun, C. L., et al. (2015). Graphene grown on stainless steel as a high-performance and ecofriendly anti-corrosion coating for polymer electrolyte membrane fuel cell bipolar plates. Journal Power Sources. https://doi.org/10.1016/j.jpowsour.2015.02.055.

Truong, V. M., Yang, M. K., & Yang, H. (2019). Functionalized carbon black supported silver (Ag/C) catalysts in cathode electrode for alkaline anion exchange membrane fuel cells. International Journal of Precision Engineering and Manufacturing Green Technology. https://doi.org/10.1007/s40684-019-00123-3.

Ji, S., Ha, J., Park, T., Kim, Y., Koo, B., Kim, Y. B., et al. (2016). Substrate-dependent growth of nanothin film solid oxide fuel cells toward cost-effective nanostructuring. International Journal of Precision Engineering and Manufacturing Green Technology. https://doi.org/10.1007/s40684-016-0005-7.

Shin, D. H., Yoo, S. R., & Lee, Y. H. (2019). Real time water contents measurement based on step response for PEM fuel cell. International Journal of Precision Engineering and Manufacturing Green Technology. https://doi.org/10.1007/s40684-019-00099-0.

Shim, J. H., Han, G. D., Choi, H. J., Kim, Y., Xu, S., An, J., et al. (2019). Atomic layer deposition for surface engineering of solid oxide fuel cell electrodes. International Journal of Precision Engineering and Manufacturing Green Technology. https://doi.org/10.1007/s40684-019-00092-7.

Ma, J., & Sahai, Y. (2013). Chitosan biopolymer for fuel cell applications. Carbohydrate Polymers. https://doi.org/10.1016/j.carbpol.2012.10.015.

Ning, F., He, X., Shen, Y., Jin, H., Li, Q., Li, D., et al. (2017). Flexible and lightweight fuel cell with high specific power density. ACS Nano. https://doi.org/10.1021/acsnano.7b01880.

Harel, F., François, X., Candusso, D., Péra, M. C., Hissel, D., & Kauffmann, J. M. (2007). PEMFC durability test under specific dynamic current solicitation linked to a vehicle road cycle. Fuel Cells. https://doi.org/10.1002/fuce.200500255.

Fathabadi, H. (2019). Combining a proton exchange membrane fuel cell (PEMFC) stack with a Li-ion battery to supply the power needs of a hybrid electric vehicle. Renewable Energy. https://doi.org/10.1016/j.renene.2018.06.104.

Sadasivuni, K. K., Deshmukh, K., Ahipa, T. N., Muzaffar, A., Ahamed, M. B., Pasha, S. K. K., et al. (2019). Flexible, biodegradable and recyclable solar cells: a review. Journal of Materials Science: Materials in Electronics. https://doi.org/10.1007/s10854-018-0397-y.

Yoon, J., Sung, H., Lee, G., Cho, W., Ahn, N., Jung, H. S., et al. (2017). Superflexible, high-efficiency perovskite solar cells utilizing graphene electrodes: Towards future foldable power sources. Energy Environment Science. https://doi.org/10.1039/c6ee02650h.

Voggu, V. R., Sham, J., Pfeffer, S., Pate, J., Fillip, L., Harvey, T. B., et al. (2017). Flexible CuInSe2 nanocrystal solar cells on paper. ACS Energy Letter. https://doi.org/10.1021/acsenergylett.7b00001.

Roldán-Carmona, C., Malinkiewicz, O., Soriano, A., Mínguez Espallargas, G., Garcia, A., Reinecke, P., et al. (2014). Flexible high efficiency perovskite solar cells. Energy Environment Science. https://doi.org/10.1039/c3ee43619e.

Park, S., Vosguerichian, M., & Bao, Z. (2013). A review of fabrication and applications of carbon nanotube film-based flexible electronics. Nanoscale. https://doi.org/10.1039/c3nr33560g.

Wang, K., Zhang, J., Wang, C., Aminirad, R., Fu, Y., Chen, P., et al. (2011). Fully printed separated carbon nanotube thin film transistor circuits and its application in organic light emitting diode control. Nano Letter. https://doi.org/10.1021/nl202765b.

Engel, M., Small, J. P., Steiner, M., Freitag, M., Green, A. A., & Hersam, M. C. (2008). Thin film nanotube transistors based on self-assembled, aligned, semiconducting carbon nanotube arrays. ACS Nano. https://doi.org/10.1021/nn800708w.

Wang, C., Chien, J. C., Takei, K., Takahashi, T., Nah, J., & Niknejad, A. M. (2012). Extremely bendable, high-performance integrated circuits using semiconducting carbon nanotube networks for digital, analog, and radio-frequency applications. Nano Letter. https://doi.org/10.1021/nl2043375.

Hu, L., Wu, H., La Mantia, F., Yang, Y., & Cui, Y. (2010). Thin, flexible secondary Li-ion paper batteries. ACS Nano. https://doi.org/10.1021/nn1018158.

Tominaka, S., Nishizeko, H., Mizuno, J., & Osaka, T. (2009). Bendable fuel cells: On-chip fuel cell on a flexible polymer substrate. Energy Environment Science. https://doi.org/10.1039/B915389F.

Weinmueller, C., Tautschnig, G., Hotz, N., & Poulikakos, D. (2010). A flexible direct methanol micro-fuel cell based on a metalized, photosensitive polymer film. Journal Power Sources. https://doi.org/10.1016/j.jpowsour.2009.12.092.

Chang, I., Park, T., Lee, J., Lee, M. H., Ko, S. H., & Cha, S. W. (2013). Bendable polymer electrolyte fuel cell using highly flexible Ag nanowire percolation network current collectors. Journal of Materials Chemistry A. https://doi.org/10.1039/c3ta11699a.

Chang, I., Park, T., Lee, J., Lee, H. B., Ji, S., & Lee, M. H. (2014). Performance enhancement in bendable fuel cell using highly conductive Ag nanowires. International Journal of Hydrogen Energy. https://doi.org/10.1016/j.ijhydene.2014.03.017.

Park, T., Chang, I., Lee, J., Ko, S. H., & Cha, S. W. (2014). Performance variation of flexible polymer electrolyte fuel cell with Ag nanowire current collector under torsion. ECS Transactions. https://doi.org/10.1149/06403.0927ecst.

Park, T., Chang, I., Jung, J. H., Lee, H. B., Ko, S. H., & O’Hayre, R. (2017). Effect of assembly pressure on the performance of a bendable polymer electrolyte fuel cell based on a silver nanowire current collector. Energy. https://doi.org/10.1016/j.energy.2017.05.197.

Kang, Y. S., Park, T., Jang, S., Choi, M., Yoo, S. J., & Cha, S. W. (2016). Repetitive bending test of membrane electrode assembly for bendable polymer electrolyte membrane fuel cell. Journal of Industrial and Engineering Chemistry. https://doi.org/10.1016/j.jiec.2016.11.048.

Kang, Y. S., Won, P., Ko, S. H., Park, T., & Yoo, S. J. (2019). Bending-durable membrane-electrode assembly using metal nanowires for bendable polymer electrolyte membrane fuel cell. Energy. https://doi.org/10.1016/j.energy.2019.01.123.

O’Hayre, R., Cha, S. W., Colella, W., & Prinz, F. (2016). Fuel cell fundamentals. Hoboken: Wiley.

Lai, X., Liu, D., Peng, L., & Ni, J. (2008). A mechanical-electrical finite element method model for predicting contact resistance between bipolar plate and gas diffusion layer in PEM fuel cells. Journal Power Sources. https://doi.org/10.1016/j.jpowsour.2008.03.069.

Asghari, S., Mokmeli, A., & Samavati, M. (2010). Study of PEM fuel cell performance by electrochemical impedance spectroscopy. International Journal of Hydrogen Energy. https://doi.org/10.1016/j.ijhydene.2010.03.069.

Hosmane, S., Fournier, A., Wright, R., Rajbhandari, L., Siddique, R., & Yang, I. H. (2011). Valve-based microfluidic compression platform: Single axon injury and regrowth. Lab on a Chip. https://doi.org/10.1039/c1lc20549h.

Lee, S. J., Chan, J. C. Y., Maung, K. J., Rezler, E., & Sundararajan, N. (2007). Characterization of laterally deformable elastomer membranes for microfluidics. Journal Micromechanics Microengineering. https://doi.org/10.1088/0960-1317/17/5/001.

Zhou, P., Wu, C. W., & Ma, G. J. (2007). Influence of clamping force on the performance of PEMFCs. Journal Power Sources. https://doi.org/10.1016/j.jpowsour.2006.09.068.

Roshandel, R., Farhanieh, B., & Saievar-Iranizad, E. (2005). The effects of porosity distribution variation on PEM fuel cell performance. Renewable Energy. https://doi.org/10.1016/j.renene.2004.11.017.

Acknowledgements

This work was supported financially by an NRF Grant funded by the Ministry of Science and ICT (2020R1C1C1009191). This research was also supported by the research fund of Hanbat National University in 2020.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Yoo, H., Kim, J., Kwon, O. et al. Pre-bent Flow-Field Plates for Enhanced Performance in Flexible Polymer Electrolyte Membrane Fuel Cells in Curved Shape. Int. J. of Precis. Eng. and Manuf.-Green Tech. 8, 869–878 (2021). https://doi.org/10.1007/s40684-020-00305-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-020-00305-4