Abstract

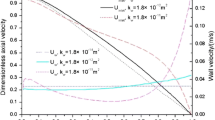

The effect of the pore size distribution on size-resolved filtration efficiency was investigated for two ceramic particulate filters using particulate matter (PM) generated by a spark-ignition direct-injection engine fueled with gasoline. The cordierite filter tested had a porosity of 43%, a median pore diameter of 12 μm, and a wide pore size distribution with a lognormal standard deviation (σ′) of 0.4. The aluminum titanate filter had very similar porosity, median pore diameter, and thickness, but significantly narrower pore size distribution (σ′ = 0.1). The testing of two filters under identical experimental conditions enabled the impact of the pore size distribution on filtration performance to be evaluated. Filtration experiments were performed focusing on just the filter wall, starting from a clean filter until the transition to cake filtration (filtration efficiency > 99%). Time-resolved particle size distribution measurements were used to evaluate the progression of filtration performance and estimate trapped mass within the filter. The aluminum titanate filter, with a narrow pore size distribution, exhibited significantly better diffusion capture efficiency. The negative impact of higher flow velocity on diffusion capture efficiency was more pronounced for a narrower pore size distribution. Flow distributions measured using capillary flow porometry were used to develop a cylindrical pore flow model to understand the impact of the differences in pore size distribution on observed trends in diffusion capture efficiency within a clean filter. The model predicted a larger impact of superficial velocity on capture efficiency for filters with narrower pore size distributions as seen from the experiments. The experimental results and data demonstrate that the bubble point diameter and width of the pore size distribution significantly influence diffusion capture efficiencies for filters with very similar median pore diameter, porosity, and thickness.

Similar content being viewed by others

Data Availability

Data supporting the findings of this study are available from the corresponding author [VS] on request.

Abbreviations

- CAD:

-

crank angle degrees

- CFP:

-

capillary flow porometry

- CoV:

-

coefficient of variation

- CPMA:

-

centrifugal particle mass analyzer

- CT:

-

computed tomography

- DMA:

-

differential mobility analyzer

- EEPS:

-

engine exhaust particle sizer

- EFA:

-

exhaust filtration analysis system

- EOI:

-

end of injection

- FE:

-

filtration efficiency

- GDI, :

-

gasoline direct ignition

- GPF:

-

gasoline particulate filter

- IMEP:

-

indicated mean effective pressure

- IPSD:

-

integrated particle size distribution

- LEP:

-

liquid extrusion porosimetry

- LIP:

-

liquid intrusion porosimetry

- MIP:

-

mercury intrusion porosimetry

- PFD:

-

partial flow diluter

- PM:

-

particulate matter

- PSD:

-

particle size distribution

- SIDI:

-

spark-ignition direct-injection

- SMPS:

-

scanning mobility particle spectrometer

References

Ohara, E., et al.: Filtration behavior of diesel particulate filters (1). In: SAE Technical Paper 2007-01-0921 (2007). https://doi.org/10.4271/2007-01-0921

Viswanathan, S., et al.: Effect of particle size distribution on the deep-bed capture efficiency of an exhaust particulate filter. J. Eng. Gas Turbines Power. 137(10), 11 (2015). https://doi.org/10.1115/1.4030098

Fukushima, S., Ohno, K., Vlachos, N., Konstandopoulos, A.: New approach for pore structure and filtration efficiency characterization. In: SAE Technical Paper, 0148-7191 (2007)

Saito, C., et al.: New particulate filter concept to reduce particle number emissions. In: SAE Technical Paper 2011-01-0814 (2011). https://doi.org/10.4271/2011-01-0814

Meng, Z., et al.: Experimental study on the influence of DPF micropore structure and particle property on its filtration process. J. Comb. 2016, 9612856, 2016/12/22 (2016). https://doi.org/10.1155/2016/9612856

Merkel, G.A., et al.: New cordierite diesel particulate filters for catalyzed and non-catalyzed applications. In: Proceedings of the 6th International Congress on Catalysis and Automotive Pollution Control (2003)

Ito, Y., et al.: Advanced ceramic wall flow filter for reduction of particulate number emission of direct injection gasoline engines. In: presented at the SAE Technical Paper 2013-01-0836 (2013. [Online]. Available). https://doi.org/10.4271/2013-01-0836

Tao, T., Cutler, W.A., Voss, K., Wei, Q.: New catalyzed cordierite diesel particulate filters for heavy duty engine applications. In: SAE Technical Paper 2003-01-3166 (2003)

y León, C.A.L.: New perspectives in mercury porosimetry. Adv. Colloid Interf. Sci. 76–77, 341–372 (1998). https://doi.org/10.1016/S0001-8686(98)00052-9

Jena, A., Gupta, K.: Characterization of pore structure of filter media. Fluid/Part. Sep. J. 14(3), 227–241 (2002)

Washburn, E.W.: Note on a method of determining the distribution of pore sizes in a porous material. Proc. Natl. Acad. Sci. U. S. A. 7(4), 115–116 (1921)

Ritter, H.L., Drake, L.C.: Pressure porosimeter and determination of complete macropore-size distributions. Ind. Eng. Chem. Anal. Ed. 17(12), 782–786 (1945). https://doi.org/10.1021/i560148a013

Allen, T.: Particle size measurement Vol 2: Surface area and pore size determination, 5th edn. Chapman and Hall, New York (1997)

Nickerson, S., Shu, Y., Zhong, D., Könke, C., Tandia, A.: Permeability of porous ceramics by X-ray CT image analysis. Acta Mater. 172, 121–130 (2019). https://doi.org/10.1016/j.actamat.2019.04.053

Kočí, P., et al.: 3D reconstruction and pore-scale modeling of coated catalytic filters for automotive exhaust gas aftertreatment. Catal. Today. 320, 165–174 (2019). https://doi.org/10.1016/j.cattod.2017.12.025

Kitagawa, J., Asami, S., Uehara, K., Hijikata, T.: Improvement of pore size distribution of wall flow type diesel particulate filter. In: SAE Technical Paper, 0148-7191 (1992)

Hashimoto, S., Miyari, Y., Hamanaka, R., Matsubara, T., Harada, T., Miwa, S.: SiC and cordierite diesel particulate filters designed for low pressure drop and catalyzed, uncatalyzed systems. In: SAE Technical Paper 2002-01-0322 (2002)

Hiratsuka, Y., Ishihara, M., Tanaka, M., Suzuki, J., Takagi, N.: The latest technology of controlling micro-pore in cordierite diesel particulate filter for DPNR system. In: SAE Technical Paper, 0148-7191 (2004)

Gong, J., et al.: Importance of filter’s microstructure in dynamic filtration modeling of gasoline particulate filters (GPFs): inhomogeneous porosity and pore size distribution. Chem. Eng. J. 338, 15–26 (2018). https://doi.org/10.1016/j.cej.2018.01.006

Konstandopoulos, A.G.: Flow resistance descriptors for diesel particulate filters: definitions, measurements and testing. In: SAE Technical Paper 2003-01-0846 (2003)

Ido, T., Ogyu, K., Ohira, A., Hayashi, M., Ohno, K., Konstandopoulos, A.G.: Study on the filter structure of SiC-DPF with gas permeability for emission control. In: SAE Technical Paper, 0148-7191 (2005)

Ohyama, N., Nakanishi, T., Daido, S.: New concept catalyzed DPF for estimating soot loadings from pressure drop. In: SAE Technical Paper, 0148-7191 (2008)

Tsuneyoshi, K., Takagi, O., Yamamoto, K.: Effects of washcoat on initial PM filtration efficiency and pressure drop in SiC DPF (2011. [Online]. Available). https://doi.org/10.4271/2011-01-0817

A. Tanaka, N. Miyoshi, and A. Sato, Development of low pressure and high performance GPF catalyst, 2018-04-03, 2018

Swanson, J., Watts, W., Kittelson, D., Newman, R., Ziebarth, R.: Filtration efficiency and pressure drop of miniature diesel particulate filters. Aerosol Sci. Technol. 47(4), 452–461 (2013). https://doi.org/10.1080/02786826.2012.763087

Matthias, N., Farron, C., Foster, D.E., Andrie, M., Krieger, R., Najt, P., Narayanaswamy, K., Solomon, A., Zelenyuk, A.: Particulate matter sampling and volatile organic compound removal for characterization of spark ignited direct injection engine emissions. SAE Int. J. Fuels Lubr. 5(1), 399–409 (2011). https://doi.org/10.4271/2011-01-2100

Beranek, J., Imre, D., Zelenyuk, A.: Real-time shape-based particle separation and detailed in situ particle shape characterization. Anal. Chem. 84(3), 1459–1465 (2012). https://doi.org/10.1021/ac202235z

Li, Y., et al.: Determination of suspended exhaust PM mass for light-duty vehicles. In: SAE Technical Paper 2014-01-1594 (2014). https://doi.org/10.4271/2014-01-1594

Viswanathan, S., Rothamer, D.A., Foster, D.E., Fansler, T.D., Zelenyuk, A., Stewart, M.L., Bell, D.M.: Evolution of deep-bed filtration of engine exhaust particulates with trapped mass. Int. J. Engine Res. 3(5-6), 2016–2559 (2016). https://doi.org/10.1177/1468087416675094

Wirojsakunchai, E., Kolodziej, C., Yapaulo, R., Foster, D.: Development of the diesel exhaust filtration analysis system (DEFA). In: presented at the SAE Technical Paper 2008-01-0486 (2008)

Viswanathan, S., Sakai, S., Rothamer, D.: Design & evaluation of an exhaust filtration analysis (EFA) system. In: presented at the SAE Technical Paper 2014-01-1558. Detroit, MI (2014)

Viswanathan, S., Rothamer, D., Zelenyuk, A., Stewart, M., Bell, D.: Experimental investigation of the effect of inlet particle properties on the capture efficiency in an exhaust particulate filter. J. Aerosol Sci. 113, 250–264, 2017/11/01/ (2017). https://doi.org/10.1016/j.jaerosci.2017.08.002

Bollerhoff, T., Markomanolakis, I., Koltsakis, G.: Filtration and regeneration modeling for particulate filters with inhomogeneous wall structure. Catal. Today. 188(1), 24–31 (2012). https://doi.org/10.1016/j.cattod.2011.12.017

Molina, J., Rothamer, D.A.: Development of the capillary flow porometry technique for the characterization of gasoline particulate filter walls. Eng. Res. Express. 1(2), 025003 (2019). https://doi.org/10.1088/2631-8695/ab4785

Viswanathan, S., Rakovec, N., Foster, D.E.: Microscale study of ash accumulation process in DPF walls using the diesel exhaust filtration analysis (DEFA) system. In: ASME 2012 Internal Combustion Engine Division Fall Technical Conference, pp. 537–549 (2012). https://doi.org/10.1115/ICEF2012-92104

Hinds, W.C.: Aerosol technology: properties, behavior, and measurement of airborne particles. John Wiley & Sons, Inc., Hoboken (1999)

Choi, H.-J., Kim, J.-U., Kim, S.H., Lee, M.-H.: Preparation of granular ceramic filter and prediction of its collection efficiency. Aerosol Sci. Technol. 48(10), 1070–1079 (2014). https://doi.org/10.1080/02786826.2014.957755

Acknowledgments

The authors would also like to thank the filter manufacturers for providing the wafer samples used in the present study.

Funding

This work was funded by General Motors through the Collaborative Research Laboratory at the University of Wisconsin-Madison Engine Research Center and the US Department of Energy (DOE), Office of Energy Efficiency and Renewable Energy, Vehicle Technology Office.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Viswanathan, S., Stewart, M.L. & Rothamer, D.A. Experimental Investigation of the Effect of Pore Size Distribution on Nano-particle Capture Efficiency Within Ceramic Particulate Filters. Emiss. Control Sci. Technol. 7, 26–40 (2021). https://doi.org/10.1007/s40825-021-00184-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40825-021-00184-4