Abstract

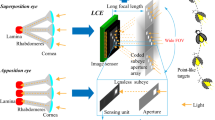

In order to achieve high speed and precision placement function, the flying vision system based on rotating mirror is proposed, the mirror is driven to rotate by the power drawn from the nozzle rise and fall movement through a rack and pinion mechanism, the nozzle pick and place functions is not interfered by mirror through designing the rack and pinion mechanism parameters. The vision system can capture an static clear chip image when the mirror rotated to a 45\(^{\circ }\) position referenced with horizontal position, the center position and rotating angle of chip is fast calculated by the fine and coarse Hough Transform Algorithm, the center location and angle will be corrected by the control system during the mounted head is flying to placement position. The experimental results show that the system can obtain high-quality microphone chip image, the chip’s center position and rotating angle correction algorithm can meet the high-speed placement requirements.

Similar content being viewed by others

References

Bartschet, M.K., Kovalchick, J.S.: Method and apparatus for chip placement . United States Patent: 4980971, (1991)

Tews, U., Rottmann, M.R.: Method and an apparatus for the positioning of components with reference to a work piece.United States Patent: 4615093, (1986)

Hudson, E.T.: Method and apparatus for reflective in-flight component registration . United States Patent: 5768759, (1998)

Hudson, E.T.: One camera systemfor component to substrate registration . United States Patent: 20010022069, (2001)

Link, D.: Apparatus for mounting a flip chip on a work piece .United Stated Patent: 6530146, (2003)

Ding, H., Zhu, L.M., Ye, Q.C.: A component locator based on reflection- of-flight flying vision. People’s Republic of China: CN 1564652A (2005)

Liu, H., Wang, Y.H., YIN, Z.P., et al.: The design of a new vision on the fly system. Opt. Technol. 32(2), 166–169 (2007)

Stefanos, Goumas, Rovithakis George, A.: An experimental vision system for SMD component placement inspection. IEEE Int. Conf. Image Process. 2, 522–549 (2002)

Tantaswadi, P.: Application of colorimetry in machine vision for checking electronic components and quility of pulp paper. Proc SPIE Int. Soc. Opt. Eng. 4535, 119–125 (2000)

Wang, Q., Cao, M., Sun, N., Fan, D.: Accurate Localization Algorithm for Rectangle Mark Based on Spatial Interpolation Technology and Combined Detection Method. 2008, 79-84

Furukawaa, Yasutaka, Shinagawa, Yoshihisa: Accurate and robust line segment extraction by analyzing distribution around peaks in Hough space. Comput. Vis. Image Underst. 92, 1–25 (2003)

Yu, Z., Bajaj, C.: Detecting circular and rectangular particles based on geometric feature detection in electron micrographs. J. Struct. Biol. 2004, 168–180

Wang, J., Zhang, M.: A new high-speed algorithm for center and rotate angle of electronic components. Proceedings of the 2006 IEEE International Conference on Mechatronics and Automaton: 2006, 228–231

Burel, G., Bernard, F., Venema, W.J.: Vision feedback for SMD placement using neural networks. Processding of 1995 IEEE International Component on Robotics and Automation 2(3), 1491–1496 (1995)

Chen, L., Zhu, j., Rong, W., Sun, L.: Flying Vision System of Placement Machine for MEMS Microphone, IEEE ICARCV (2010)

Acknowledgements

The authors would like to acknowledge the Natural Science Foundation of Jiangsu Province of China (the Grant Number BK20131195), the National Science Foundation of China (the Grant Number 61106110).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jian, C., Maohai, L., Rui, L. et al. Flying Vision System Design of Placement Machine for Microphone. Intell Ind Syst 3, 5–14 (2017). https://doi.org/10.1007/s40903-017-0070-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40903-017-0070-4