Abstract

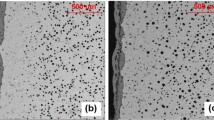

High alloyed Si ferritic ductile irons can offer potential benefits because they combine high strength, ductility at room temperature, and low oxidation rate at high temperature. However, there is one known drawback and that is these cast irons have limited performance during thermal cycling due to a significant drop of ductility at warm temperatures. This decrease in ductility has been linked to poisoning ferrite grain boundaries by Mg. Therefore, thermodynamic simulations were used to identify altering additions which were able to meditate this negative effect by forming intermetallic phases with Mg. To verify thermodynamic predictions, three alloys were cast including a base and two high Si ductile irons with additions of P and Sb. High-temperature performance of these alloys was experimentally verified including tensile properties at warm temperatures (350–550 °C), oxidation in air at temperatures (700–800 °C), and thermal cycling between 300 and 800 °C. SEM and TEM analyses confirmed that the studied additions reacted with Mg forming different compounds which could prevent poisoning ferrite grain boundaries and improve high-temperature performance of high Si ductile iron.

Similar content being viewed by others

Change history

20 October 2020

A Correction to this paper has been published: https://doi.org/10.1007/s40962-020-00534-y

References

European Standard EN-1563: Spheroidal graphite cast irons (2018)

R. Larker, China Found. 6(4), 343–351 (2009)

F. Tholence, M. Norell, Oxid. Met. 69, 13 (2008)

M. Ekström, P. Szakalos, S. Jonsson, Oxid. Met. 80(5–6), 455 (2013)

N. Scheidhauer, C. Dommaschk, G. Wolf, Mater. Sci. Forum 925, 393 (2017)

P. Weiß, Mater. Sci. Eng. A 713, 67 (2018)

M. Takanezawa, Y. Tomota, Y. Kobayashi, ISIJ Int. 38(1), 106 (1998)

T.S. Lui, C.G. Chao, J. Mater. Sci. 24, 2503 (1989)

J. Laine, K. Jalava, J. Vaara et al., The mechanical properties of ductile iron at intermediate temperatures: the effect of silicon content and pearlite fraction. Inter Metalcast (2020). https://doi.org/10.1007/s40962-020-00473-8

M. Ekström, Oxidation and Corrosion Fatigue Aspects of Cast Exhaust Manifolds, Doctoral Thesis, Stockholm, Sweden (2015)

D.G. Bon, M.H. Ferreira, W.W. Bose Filho et al., Fracture micromechanisms evaluation of high-strength cast irons under thermomechanical fatigue conditions. Inter Metalcast 14, 696–705 (2020). https://doi.org/10.1007/s40962-019-00399-w

K. Roehrig, Thermal fatigue of gray and ductile irons. AFS Trans 86, 75–88 (1978)

E. Pan, C. Fan, H. Chang, High temperature thermal fatigue property of thin-section ductile cast iron. AFS Trans. 118, 265–276 (2010)

X. Wu, G. Quan, R. Macheil, Z. Zang, X. Liu, C. Sloss, Metal. Mater. Trans. A 46A, 2530 (2015)

X. Wu, G. Quan, R. Macheil, Z. Zang, X. Liu, C. Sloss, Metal. Mater. Trans. A 45A, 5085 (2014)

K. Avery, PhD Thesis, The University of Michigan (2016)

O. Celik, H. Ahlatci, E. Kayali, H. Cimenog, ISIJ Int. 43(8), 1274 (2003)

X. Wu, G. Quan, R. Macheil, Z. Zang, X. Liu, C. Sloss, Metal. Mater. Trans. A 45A, 2014 (2014)

M. Takanezawa, Y. Kobayashi, Y. Tomota, J. JFS 69, 41 (1997)

C. Cheng, T. Lui, L. Chen, Metal. Mater. Trans. A 30A(06), 1549 (1999)

H. Lin, T. Lui, L. Chen, Metal. Mater. Trans. A 44A(6), 1209 (2003)

O. Yanagisawa, J. JFS 72, 604 (2000)

T. Kanno, Problems and improvements on the production of large casting with Hi–Si ductile iron. Inter Metalcast 13, 491–499 (2019)

D. Li, C. Sloss, Brittleness at medium temperature of spheroidal graphite, mixed graphite, and compacted graphite high-silicon molybdenum cast irons. AFS Trans. 132, 243–253 (2015)

O. Tsumura, Y. Ichinomiya, T. Miyamoto, T. Takenouchi, Imono 67(8), 540 (1995)

L. Dekker, B. Tonn, G. Lilienkamp, Effect of antimony on graphite growth in ductile iron. Inter Metalcast 14, 827–835 (2020). https://doi.org/10.1007/s40962-020-00434-1

Z. Yuan, A. Guo, S. Chen, D. Shen, J. Jia, S. Song, J. Mater. Sci. Lett. 22, 311 (2003)

S. Lekakh, V. Richards, N. Medvedeva, Effect of Si segregation on low temperature toughness of ductile iron. AFS Trans. 120, 319–327 (2012)

D. Franzen, P. Weiß, B. Pustal, A. Bührig-Polaczek, Mater. Sci. Technol. 35(6), 687 (2019)

P. Weiß, A. Tekavčič, A. Bührig-Polaczek, Mater. Sci. Eng. A 713(24), 67 (2018)

S. Lekakh, V. Richards, Diffusion modeling and experimental verification of pearlite/ferrite formation in ductile iron. AFS Trans. 118, 225–232 (2010)

S. Lekakh, Metal. Mater. Trans. B 50B, 890 (2019)

FACTSAGE 7.3 thermodynamic software. www.factsage.com

Adaptive thermal analysis (ATAS), Novacast, SE. https://www.novacast.se/product/atas/ATAS

T. Hara, K. Kuroki, S. Ikeno, S. Saikawa, K. Terayama, K. Matsuda, in The 8th Pacific Rim International Congress on Advanced Materials and Processing Edited by: Fernand Marquis, TMS (2013)

L. Zhe, C. Weiping, D. Yu, China Foundry 9(2), 114 (2012)

K. Theuwissen, J. Lacaza, L. Laffont, Carbon 96, 1120 (2016)

K. Jalava, K. Soivio, J. Laine et al., Effect of silicon and microstructure on spheroidal graphite cast iron thermal conductivity at elevated temperatures. Inter Metalcast 12, 480–486 (2018). https://doi.org/10.1007/s40962-017-0184-1

Acknowledgements

This material is based upon work supported by the U.S. Department of Energy’s Office of Energy Efficiency and Renewable Energy (EERE) under the Award Number DE-EE0008458. We thank Dr. Wei-Ting Chen for TEM work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this article was revised: In the original version of the article, Fig. 4b was processed incorrectly by the publisher.

Rights and permissions

About this article

Cite this article

Lekakh, S.N., Johnson, C., Bofah, A. et al. Improving High-Temperature Performance of High Si-Alloyed Ductile Iron by Altering Additions. Inter Metalcast 15, 874–888 (2021). https://doi.org/10.1007/s40962-020-00524-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-020-00524-0