Abstract

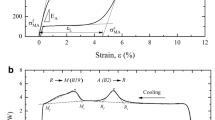

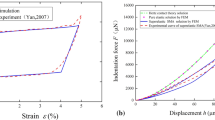

NiTi-based shape memory alloys are considered as potential candidates for various structural, functional and biomedical applications. This is particularly related to their unique characteristics such as pseudoelastic and shape memory effects. Considering the increasing demand of NiTi alloys in miniaturized devices, the small-scale deformation micro-mechanisms of such a material system is being thoroughly reviewed in this article. At the first hand, the fundamental characteristics of NiTi system is discussed briefly. The influence of different factors such as chemical composition, crystallographic phases and precipitates on the phase transformation and mechanical behavior of the material are emphasized next. Subsequently, an extensive overview is provided regarding the assessment of small-scale deformation behavior of NiTi alloys using two prime techniques: micro-pillar compression and instrumented nanoindentation. Pros and cons for both the characterization techniques are analyzed as well. Interestingly, uniaxial compression of the micro-pillar reveals the pseudoelastic behavior in the alloy with remarkable enhancement in martensitic transformation stress and plateau strain with respect to those observed from macro-scale testing. It is also evident from the studies that mechanical behavior of the material strongly depends on different crystallographic orientation. Contrary to the uniaxial compression, nanoindentation generates triaxial state of stress beneath the tip of indenter, which is likely to influence the deformation micro-mechanism for the NiTi system, as well. Variation in hardness, elastic modulus and recoverability of NiTi system are primarily assessed through nanoindentation-based studies. In addition, recent studies highlight the importance of optimizing the nanoindentation parameters such as tip configuration, tip radius and load level for precise estimation of pseudoelastic activity in the alloy. Moreover, a simplified approach is generated for estimating the indentation stress–indentation strain curve. Overall, this paper generates a thorough and comprehensive insight about the micro-mechanical testing of NiTi-based shape memory alloys.

Similar content being viewed by others

References

Senthilnathan K (2010) Pseudoelastic shape memory alloy model with stent deployment simulation. ProQuest Dissertations Publishing, State University of New York at Buffalo, USA

Otsuka K, Ren X (2005) Physical metallurgy of Ti–Ni-based shape memory alloys. Prog Mater Sci 50:511–678. https://doi.org/10.1016/j.pmatsci.2004.10.001

Stoeckel D, Melzer A (1995) The use of niti alloys for surgical instruments. In: Materials in clinical applications, pp 791–798. www.nitinol.com

Mehrpouya M, Bidsorkhi HC (2017) MEMS applications of NiTi based shape memory alloys: a review. Micro Nanosyst 8:79–91. https://doi.org/10.2174/1876402908666161102151453

Ozbulut OE, Daghash S, Sherif MM (2016) Shape memory alloy cables for structural applications. J Mater Civ Eng 28:04015176. https://doi.org/10.1061/(asce)mt.1943-5533.0001457

Quan D, Hai X (2015) Shape memory alloy in various aviation field. Proc Eng 99:1241–1246. https://doi.org/10.1016/j.proeng.2014.12.654

Csanádi T, Naughton-Duszová A, Dusza J (2018) Anisotropic slip activation via homogeneous dislocation nucleation in ZrB2 ceramic grains during nanoindentation. Scr Mater 152:89–93. https://doi.org/10.1016/j.scriptamat.2018.04.025

Jacob K, Yadav D, Dixit S, Hohenwarter A, Jaya BN (2021) High pressure torsion processing of maraging steel 250: microstructure and mechanical behaviour evolution. Mater Sci Eng A 802:140665. https://doi.org/10.1016/j.msea.2020.140665

Ozdemir N, Karaman I, Mara NA, Chumlyakov YI, Karaca HE (2012) Size effects in the superelastic response of Ni 54Fe 19Ga 27 shape memory alloy pillars with a two stage martensitic transformation. Acta Mater 60:5670–5685. https://doi.org/10.1016/j.actamat.2012.06.035

Bhargava AK, Sharma CP (2011) Mechanical behaviour and testing of materials. Prentice Hall India Learning Private Limited, India

François D, Pineau A, Zaoui A (1998) Mechanical behaviour of materials. Springer, Netherlands

Shetty MN (2013) Dislocations and mechanical behaviour of materials. Prentice Hall India Learning Private Limited, India

Hopulele I, Istrate S, Stanciu S, Calugaru G (2004) Comparative study of certain Cu-Zn-Al-type alloys concerning their superelastic behavior and shape memory. J Optoelectron Adv Mater 6:277–282

Gall K, Sehitoglu H, Chumlyakov YI, Kireeva IV (1999) Tension-compression asymmetry of the stress-strain response in aged single crystal and polycrystalline NiTi. Acta Mater 47:1203–1217. https://doi.org/10.1016/S1359-6454(98)00432-7

Patoor E, Lagoudas DC, Entchev PB, Brinson LC, Gao X (2006) Shape memory alloys, part I: general properties and modeling of single crystals. Mech Mater 38:391–429. https://doi.org/10.1016/j.mechmat.2005.05.027

Kumar S, Kumar IA, Marandi L, Sen I (2020) Assessment of small-scale deformation characteristics and stress-strain behavior of NiTi based shape memory alloy using nanoindentation. Acta Mater 201:16375. https://doi.org/10.1016/j.actamat.2020.09.080

Young ML, Wagner MFX, Frenzel J, Schmahl WW, Eggeler G (2010) Phase volume fractions and strain measurements in an ultrafine-grained NiTi shape-memory alloy during tensile loading. Acta Mater 58:2344–2354. https://doi.org/10.1016/j.actamat.2009.12.021

Ahadi A, Sun Q (2013) Stress hysteresis and temperature dependence of phase transition stress in nanostructured NiTi—effects of grain size. Appl Phys Lett. https://doi.org/10.1063/1.4812643

Elibol C, Wagner MFX (2015) Investigation of the stress-induced martensitic transformation in pseudoelastic NiTi under uniaxial tension, compression and compression-shear. Mater Sci Eng A 621:76–81. https://doi.org/10.1016/j.msea.2014.10.054

Saburi T, Yoshida M, Nenno S (1984) Deformation behavior of shape memory Ti-Ni alloy crystal. Scr Metall 18:363–366

Basu R, Jain L, Maji BC, Krishnan M, Mani Krishna KV, Samajdar I, Pant P (2012) Origin of microstructural irreversibility in Ni-Ti based shape memory alloys during thermal cycling. Metall Mater Trans A Phys Metall Mater Sci 43:1277–1287. https://doi.org/10.1007/s11661-011-0970-y

Kumar PK, Lagoudas DC (2010) Shape memory alloys. Shape Mem Alloy. https://doi.org/10.1007/978-0-387-47685-8-1

Superelastic tire (n.d.). https://technology.nasa.gov/patent/LEW-TOPS-99

Van Humbeeck J (1999) Non-medical applications of shape memory alloys. Mater Sci Eng A 273:134–148. https://doi.org/10.1016/S0921-5093(99)00293-2

Garay JE, Anselmi-Tamburini U, Munir ZA (2003) Enhanced growth of intermetallic phases in the Ni-Ti system by current effects. Acta Mater 51:4487–4495. https://doi.org/10.1016/S1359-6454(03)00284-2

Thompson SA (2000) An overview of nickel-titanium alloys used in dentistry. Int Endod J 33:297–310. https://doi.org/10.1046/j.1365-2591.2000.00339.x

Fei X, Connell CJO, Grummon DS, Cheng YT (2011) Surface form memory by indentation and planarization of NiTi: displacements and mechanical energy density during constrained recovery. J Mater Sci 46:7401–7409. https://doi.org/10.1007/s10853-011-5702-6

Zhou Y, Zhang J, Fan G, Ding X, Sun J, Ren X, Otsuka K (2005) Origin of 2-stage R-phase transformation in low-temperature aged Ni-rich Ti-Ni alloys. Acta Mater 53:5365–5377. https://doi.org/10.1016/j.actamat.2005.08.013

Khalil-Allafi J, Dlouhy A, Eggeler G (2002) Ni4Ti3-precipitation during aging of NiTi shape memory alloys and its influence on martensitic phase transformations. Acta Mater 50:4255–4274. https://doi.org/10.1016/S1359-6454(02)00257-4

Dey SK, Sen I, Samanta S (2021) Mechanical characterisation of PEEK-HA composite as an orthopaedic implant. Adv Mater Process Technol. https://doi.org/10.1080/2374068X.2021.1970990

Kousbroek R (1990) Shape memory alloys. In: ASM Handbook, Prop. Sel. Nonferrous Alloy. Spec. Mater., vol 2, pp 897–902. https://doi.org/10.1201/9781351074438

Mentz J, Frenzel J, Wagner MFX, Neuking K, Eggeler G, Buchkremer HP, Stöver D (2008) Powder metallurgical processing of NiTi shape memory alloys with elevated transformation temperatures. Mater Sci Eng A 491:270–278. https://doi.org/10.1016/j.msea.2008.01.084

Hodgson DE, Biermann RJ (1990) Shape memory alloys. In: ASM Handbook, Prop. Sel. Nonferrous Alloy. Spec. Mater., vol 2, pp 897–901. https://doi.org/10.1201/9781351074438

Jiang SY, Zhao YN, Zhang YQ, Hu L, Liang YL (2013) Effect of solution treatment and aging on microstructural evolution and mechanical behavior of NiTi shape memory alloy. Trans Nonferrous Met Soc China (English Ed) 23:3658–3667. https://doi.org/10.1016/S1003-6326(13)62914-3

Wadood A (2016) Brief overview on nitinol as biomaterial. Adv Mater Sci Eng. https://doi.org/10.1155/2016/4173138

Duerig TW, Bhattacharya K (2015) The Influence of the R-phase on the superelastic behavior of NiTi. Shape Mem Superelast 1:153–161. https://doi.org/10.1007/s40830-015-0013-4

Huang X, Ackland GJ, Rabe KM (2003) Crystal structures and shape-memory behaviour of NiTi. Nat Mater 2:307–311. https://doi.org/10.1038/nmat884

Khalil-Allafi J, Schmahl WW, Toebbens DM (2006) Space group and crystal structure of the R-phase in binary NiTi shape memory alloys. Acta Mater 54:3171–3175. https://doi.org/10.1016/j.actamat.2006.02.040

Bataillard L, Bidaux J, Gotthardt R (2009) Interaction between microstructure and multiple- step transformation in binary NiTi alloys using in-situ transmission electron microscopy observations. Philos Mag A. https://doi.org/10.1080/01418619808241907

Gall K, Sehitoglu H (2012) The role of texture in tension ± compression asymmetry in polycrystalline NiTi. Int J Plast 15:1–24

Arciniegas M, Casals J, Manero JM, Peña J, Gil FJ (2008) Study of hardness and wear behaviour of NiTi shape memory alloys. J Alloys Compd 460:213–219. https://doi.org/10.1016/j.jallcom.2007.05.069

Bhagyaraj J, Ramaiah KV, Saikrishna CN, Bhaumik SK (2013) Gouthama, behavior and effect of Ti2Ni phase during processing of NiTi shape memory alloy wire from cast ingot. J Alloys Compd 581:344–351. https://doi.org/10.1016/j.jallcom.2013.07.046

Buehler WJ, Gilfrich JV, Wiley RC (1963) Effect of low-temperature phase changes on the mechanical properties of alloys near composition TiNi. J Appl Phys 34:1475–1477. https://doi.org/10.1063/1.1729603

Zou WH, Han XD, Wang R, Zhang Z, Zhang WZ, Lai JKL (1996) TEM and HREM study of the interphase interface structure of Ti3Ni4 precipitates and parent phase in an aged TiNi shape memory alloy. Mater Sci Eng A 219:142–147. https://doi.org/10.1016/S0921-5093(96)10418-4

Carroll MC, Somsen C, Eggeler G (2004) Multiple-step martensitic transformations in Ni-rich NiTi shape memory alloys. Scr Mater 50:187–192. https://doi.org/10.1016/j.scriptamat.2003.09.020

Fei H, Abraham A, Chawla N, Jiang H (2012) Evaluation of micro-pillar compression tests for accurate determination of elastic-plastic constitutive relations. J Appl Mech 79:061011. https://doi.org/10.1115/1.4006767

Greer JR, De Hosson JTM (2011) Plasticity in small-sized metallic systems: intrinsic versus extrinsic size effect. Prog Mater Sci 56:654–724. https://doi.org/10.1016/j.pmatsci.2011.01.005

Dehm G, Jaya BN, Raghavan R, Kirchlechner C (2018) Overview on micro- and nanomechanical testing: new insights in interface plasticity and fracture at small length scales. Acta Mater 142:248–282. https://doi.org/10.1016/j.actamat.2017.06.019

Greer JR, Oliver WC, Nix WD (2005) Size dependence of mechanical properties of gold at the micron scale in the absence of strain gradients. Acta Mater 53:1821–1830. https://doi.org/10.1016/j.actamat.2004.12.031

Uchic MD, Dimiduk DM, Florando JN, Nix WD (2004) Sample dimensions influence strength and crystal plasticity. Science (80-) 305:986–989. https://doi.org/10.1126/science.1098993

Greer JR, Weinberger CR, Cai W (2008) Comparing the strength of f.c.c. and b.c.c. sub-micrometer pillars: compression experiments and dislocation dynamics simulations. Mater Sci Eng A 493:21–25. https://doi.org/10.1016/j.msea.2007.08.093

Hou XD, Bushby AJ, Jennett NM (2008) Study of the interaction between the indentation size effect and Hall-Petch effect with spherical indenters on annealed polycrystalline copper. J Phys D Appl Phys 41:74006

Leitner A, Maier-Kiener V, Kiener D (2017) Extraction of flow behavior and Hall-Petch parameters using a nanoindentation multiple sharp tip approach. Adv Eng Mater 19:1600669

Lehto P, Remes H, Saukkonen T, Hänninen H, Romanoff J (2014) Influence of grain size distribution on the Hall-Petch relationship of welded structural steel. Mater Sci Eng A 592:28–39

Frick CP, Orso S, Arzt E (2007) Loss of pseudoelasticity in nickel-titanium sub-micron compression pillars. Acta Mater 55:3845–3855. https://doi.org/10.1016/j.actamat.2007.02.034

Manjeri RM, Qiu S, Mara N, Misra A, Vaidyanathan R (2010) Superelastic response of [111] and [101] oriented NiTi micropillars. J Appl Phys. https://doi.org/10.1063/1.3445262

Juan JS, Nó ML, Schuh CA (2009) Nanoscale shape-memory alloys for ultrahigh mechanical damping. Nat Nanotechnol 4:415–419. https://doi.org/10.1038/nnano.2009.142

Pfetzing-Micklich J, Ghisleni R, Simon T, Somsen C, Michler J, Eggeler G (2012) Orientation dependence of stress-induced phase transformation and dislocation plasticity in NiTi shape memory alloys on the micro scale. Mater Sci Eng A 538:265–271. https://doi.org/10.1016/j.msea.2012.01.042

Ye J, Mishra RK, Pelton AR, Minor AM (2010) Direct observation of the NiTi martensitic phase transformation in nanoscale volumes. Acta Mater 58:490–498. https://doi.org/10.1016/j.actamat.2009.09.027

Clarke AJ, Field RD, Dickerson PO, McCabe RJ, Swadener JG, Hackenberg RE, Thoma DJ (2009) A microcompression study of shape-memory deformation in U-13 at.% Nb. Scr Mater 60:890–892. https://doi.org/10.1016/j.scriptamat.2009.02.003

Norfleet DM, Sarosi PM, Manchiraju S, Wagner MFX, Uchic MD, Anderson PM, Mills MJ (2009) Transformation-induced plasticity during pseudoelastic deformation in Ni-Ti microcrystals. Acta Mater 57:3549–3561. https://doi.org/10.1016/j.actamat.2009.04.009

Frick CP, Clark BG, Schneider AS, Maaß R, Van Petegem S, Van Swygenhoven H (2010) On the plasticity of small-scale nickel-titanium shape memory alloys. Scr Mater 62:492–495. https://doi.org/10.1016/j.scriptamat.2009.12.023

Clark BG, Gianola DS, Kraft O, Frick CP (2010) Size independent shape memory behavior of nickel-titanium. Adv Eng Mater 12:808–815. https://doi.org/10.1002/adem.201000048

Paul PP, Kabirifar P, Sun Q, Brinson LC (2019) Structure-microstructure interactions in compression deformation of NiTi shape memory alloy micropillars. Mater Lett 257:126693. https://doi.org/10.1016/j.matlet.2019.126693

Gall K, Sehitoglu H, Anderson R, Karaman I, Chumlyakov YI, Kireeva IV (2001) On the mechanical behavior of single crystal NiTi shape memory alloys and related polycrystalline phenomenon. Mater Sci Eng A 317:85–92

Frick CP, Clark BG, Orso S, Sonnweber-Ribic P, Arzt E (2008) Orientation-independent pseudoelasticity in small-scale NiTi compression pillars. Scr Mater 59:7–10. https://doi.org/10.1016/j.scriptamat.2008.01.051

San Juan JM, Nó ML, Schuh CA (2008) Superelasticity and shape memory in micro- and nanometer-scale pillars. Adv Mater 20:272–278. https://doi.org/10.1002/adma.200701527

Pfetzing-Micklich J, Wagner MFX, Zarnetta R, Frenzel J, Eggeler G, Markaki AE, Wheeler J, Clyne TW (2010) Nanoindentation of a pseudoelastic NiTiFe shape memory alloy. Adv Eng Mater 12:13–19. https://doi.org/10.1002/adem.200900266

Oliver WC, Pharr GM (2004) Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J Mater Res 19:3–20. https://doi.org/10.1557/jmr.2004.19.1.3

Murase K, Morrison KL, Tam PY, Stafford RL, Jurnak F, Weiss GA (2003) EF-Tu binding peptides identified, dissected, and affinity optimized by phage display GDP conformation of EF-Tu. Because EF-Tu is abundant in the cell, other functions have been suggested, particularly during periods of cellular stress when protein syn-g. Chem Biol 10:161–168

Il Jang J, Lance MJ, Wen S, Tsui TY, Pharr GM (2005) Indentation-induced phase transformations in silicon: influences of load, rate and indenter angle on the transformation behavior. Acta Mater 53:1759–1770. https://doi.org/10.1016/j.actamat.2004.12.025

Field JS, Swain MV (1993) A simple predictivity model for spherical indentation. J Mater Res 8:297–306. https://doi.org/10.1557/JMR.1993.0297

Muir Wood AJ, Sanjabi S (2008) Nanoindentation of binary and ternary Ni-Ti-based shape memory alloy thin films. Surf Coat Technol 202:3115–3120. https://doi.org/10.1016/j.surfcoat.2007.11.011

Shaw GA, Stone DS, Johnson AD, Ellis AB, Crone WC (2003) Shape memory effect in nanoindentation of nickel-titanium thin films. Appl Phys Lett 83:257–259. https://doi.org/10.1063/1.1591235

Yan W, Sun Q, Feng XQ, Qian L (2007) Analysis of spherical indentation of superelastic shape memory alloys. Int J Solids Struct 44:1–17. https://doi.org/10.1016/j.ijsolstr.2006.04.007

Amini A, He Y, Sun Q (2011) Loading rate dependency of maximum nanoindentation depth in nano-grained NiTi shape memory alloy. Mater Lett 65:464–466. https://doi.org/10.1016/j.matlet.2010.10.026

Crone WC, Shaw GA, Stone DS, Johnson AD, Ellis AB (2003) Shape recovery after nanoindentation of NiTi thin films. In: 2003 SEM Annu. Conf. Expo. Exp. Appl. Mech., pp 1–6

Li P, Karaca HE, Cheng YT (2017) Rapid characterization of local shape memory properties through indentation. Sci Rep 7:1–8. https://doi.org/10.1038/s41598-017-13434-9

Zhang Y, Cheng YT, Grummon DS (2006) Two-way indent depth recovery in a NiTi shape memory alloy. Appl Phys Lett 88:3–5. https://doi.org/10.1063/1.2189201

Laursen CM, Peter NJ, Gerstein G, Maier HJ, Dehm G, Frick CP (2020) Influence of Ti3Ni4 precipitates on the indentation-induced two-way shape-memory effect in Nickel-Titanium. Mater Sci Eng A 792:139373. https://doi.org/10.1016/j.msea.2020.139373

Su JF, Huang WM, Hong MH (2007) Indentation and two-way shape memory in a NiTi polycrystalline shape-memory alloy. Smart Mater Struct. https://doi.org/10.1088/0964-1726/16/1/S14

Gall K, Juntunen K, Maier HJ, Sehitoglu H, Chumlyakov YI (2001) Instrumented micro-indentation of NiTi shape-memory alloys. Acta Mater 49:3205–3217. https://doi.org/10.1016/S1359-6454(01)00223-3

Pfetzing-Micklich J, Somsen C, Dlouhy A, Begau C, Hartmaier A, Wagner MFX, Eggeler G (2013) On the crystallographic anisotropy of nanoindentation in pseudoelastic NiTi. Acta Mater 61:602–616. https://doi.org/10.1016/j.actamat.2012.09.081

Laplanche G, Pfetzing-Micklich J, Eggeler G (2014) Orientation dependence of stress-induced martensite formation during nanoindentation in NiTi shape memory alloys. Acta Mater 68:19–31. https://doi.org/10.1016/j.actamat.2014.01.006

Sujith Kumar S, Sen I (2021) A comparative study on deformation behaviour of superelastic NiTi with traditional elastic-plastic alloys in sub-micron scale. Trans Indian Inst Met. https://doi.org/10.1007/s12666-021-02207-8

Sen I, Sujith Kumar S (2021) Characterizing stress-strain behavior of materials through nanoindentation. INTECH. https://doi.org/10.5772/intechopen.98495

Pathak S, Kalidindi SR (2015) Spherical nanoindentation stress-strain curves. Mater Sci Eng R Rep 91:1–36. https://doi.org/10.1016/j.mser.2015.02.001

Pathak S, Shaffer J, Kalidindi SR (2009) Determination of an effective zero-point and extraction of indentation stress-strain curves without the continuous stiffness measurement signal. Scr Mater 60:439–442. https://doi.org/10.1016/j.scriptamat.2008.11.028

Kalidindi SR, Pathak S (2008) Determination of the effective zero-point and the extraction of spherical nanoindentation stress-strain curves. Acta Mater 56:3523–3532. https://doi.org/10.1016/j.actamat.2008.03.036

Kumar S, Marandi L, Balla VK, Bysakh S, Piorunek D, Eggeler G, Das M, Sen I (2019) Microstructure—property correlations for additively manufactured NiTi based shape memory alloys. Materialia 8:100456. https://doi.org/10.1016/j.mtla.2019.100456

Šittner P, Heller L, Pilch J, Curfs C, Alonso T, Favier D (2014) Young’s modulus of austenite and martensite phases in superelastic NiTi wires. J Mater Eng Perform. https://doi.org/10.1007/s11665-014-0976-x

Acknowledgements

The authors thankfully acknowledge the financial support from Indian Institute of Technology, Kharagpur and Science and Engineering Research Board, Department of Science and Technology, India through research grants IIT/SRIC/MET/SNA/2014-15/161 and YSS/2015/000976, respectively.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kumar, S.S., Arohi, A.C. & Sen, I. A Review on Micro-mechanical Testing of NiTi-Based Shape Memory Alloys. J Indian Inst Sci 102, 211–235 (2022). https://doi.org/10.1007/s41745-021-00278-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41745-021-00278-6