Abstract

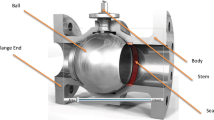

One of the most important issues in the valve industry is the mechanical integrity between the valves and the actuators. Applied loads from the actuator that exceed the maximum load that can be tolerated by the valve stem pose a great risk to this integrity. This study develops a flowchart for ensuring the integrity between the valve and the actuator by adopting at least one of the following solutions: adding a pressure safety valve on the control panel of pneumatic actuators, reducing the spring torque of the actuators, and increasing the MAST by upgrading the material and/or increasing the stem diameter. Five actuated fail-safe closed ball valves were analyzed in terms of valve and actuator torques at five points and with air pressures of 5.5, 7, and 9 bar as well as the MAST. The MAST and integrity between the valve and the actuator did not pose problems in two cases; the use of at least one of the abovementioned solutions is proposed to ensure integrity between the valve and the actuator in terms of the MAST and actuator torque in the other three cases.

Graphical abstract

Similar content being viewed by others

Availability of data and materials

Not applicable. If your manuscript does not contain any data, please state 'Not applicable' in this section.

References

B. Nesbitt, Handbook of Valves and Actuators: Valves Manual International, 1st edn. (Elsevier, Oxford, 2007)

P. Smit, R.W. Zappe, Valve Selection Handbook, 5th edn. (Elsevier, New York, 2004)

K. Sotoodeh, Prevention of Actuator Emissions in the Oil and Gas Industry (Gulf Professional Publishing, Austin, 2021)

K. Sotoodeh, Actuator selection and sizing for valves. Spring. Nat. Appl. Sci. 1, 1207 (2019). https://doi.org/10.1007/s42452-019-1248-z

American Petroleum Institute (API) 6DX, Petroleum and Natural Gas Industries—Mechanical Integrity and Sizing of Actuators and Mounting Kits for Pipeline Valves (1st ed.). Washington DC, USA (2012)

International Organization for Standardization (ISO) 12490, Industrial Valves—Petroleum and Natural Gas Industries—Mechanical Integrity and Sizing of Actuators and Mounting Kits for Pipeline Valves, 1st edn. (Switzerland, Geneva, 2011)

K. Sotoodeh, Valves and actuators integrity and blast load calculations. Sprin. Nat. Appl. Sci. 1, 599 (2019). https://doi.org/10.1007/s42452-019-0624-z

Det Norske Veritas (DNV), Structural Analysis of Piping System. Recommended practice DNV-RP-D101. Hovik, Norway (2008)

J.K. Paik, J. Czujko, B.J. Kim et al., Quantitative assessment of hydrocarbon exposition and fire risks in offshore installation. Mar. Struct. 24(2), 73–96 (2011). https://doi.org/10.1016/j.marstruc.2011.02.002

H. Rozuhan, M. Muhammad, M.U. Niazi, Probabilistic risk assessment of offshore installation hydrocarbon releases leading to fire and explosion, incorporating system and human reliability analysis. Appl. Ocean Res. 101, 102282 (2020). https://doi.org/10.1016/j.apor.2020.102282

K. Sotoodeh, Safety and Reliability Improvements of Valves and Actuators for the Offshore Oil and Gas Industry Through Optimized Design. University of Stavanger. PhD thesis UiS, no. 573 (2021)

K. Sotoodeh, Development of a numeric method to validate the reliability improvement of safety critical valves during operation through online monitoring implementation. J. Sens. Imaging. 21, 57 (2020). https://doi.org/10.1007/s11220-020-00323-1

T. Juvik, R. Carr, T. Hermansen, & S. Hale, Online valve monitoring system used on off-shore platforms in the North Sea. 21st International Conference on Offshore Mechanics and Arctic Engineering. ASME. Oslo, Norway. Paper No. OMAE2002–28403 (2002)

A. Lemme, H.J. Furseth, Expansion of the Condition Monitoring Strategy for ESD and PSD Valves on Johan Sverdrup Phase 1—A Case Study in Equinor ASA (University of Stavanger. Faculty of Science and Technology, 2019)

American Petroleum Institute (API) 6D, Specification for pipeline and piping valves, 24th edn. (API, Washington, 2014)

International Organization for Standardization (ISO) 14313. Pipeline transportation systems: Pipeline valves (2nd ed.).

K. Sotoodeh, The importance of maximum allowable stem torque in valves. Spring. Nat. Appl. Sci. 1, 433 (2019). https://doi.org/10.1007/s42452-019-0445-0

K. Sotoodeh, Optimized valve stem design in oil and gas industry to minimize major failures. J. Fail. Anal. Prev. 20, 634–640 (2020). https://doi.org/10.1007/s11668-020-00891-0

D. Kim, Weak-link analysis of motor operated butterfly valve. The American Society of Mechanical Engineers (ASME) International Joint Power Generation Conference. June 24–26, Arizona, USA (2009)

J.K. Sangolt, M. Bjoroy, & T. Erstad, Application of industry 4.0 concepts for increasing reliability of valves. Western Norway University of Applied Sciences. Department of Mechanical and Marine Engineering (2019)

H.Y. Sim, R. Ramli, A. Saifizul, M.F. Soong, Detection and estimation of valve leakage losses in reciprocating compressor using acoustic emission technique. Measurement 152, 107315 (2020)

S.B. Zhu, Z.L. Li, S.M. Zhang, Y. Yu, H.F. Zhang, Deep belief network-based interval valve leakage rate prediction approach. Measurement 133, 182–192 (2019)

K. Sotoodeh, A review of valve stem sealing to prevent leakage from the valve and its effect on valve operation. J. Fail. Anal. Prev. 21(1), 9–16 (2020)

L. Jon-Anders, Testing and Performance of Production-and Safety Critical Valves Used in Gas Pipeline. Master thesis. University of Stavanger. Masteroppgave/UIS-TN-IKM/2015 (2015)

E. Meland, Condition evaluation of safety critical shut down valves. International Conference of Offshore Mechanics and Arctic Engineering. May and June. Honolulu, USA. Paper No: OMAE2009–79968, pp. 693–699 (2010)

B. Hannaford, J. Winters, Actuator properties and movement control: Biological and technological models, in Multiple Muscle Systems. ed. by J.M. Winters, S.L.Y. Woo (Springer, New York, 1990). https://doi.org/10.1007/978-1-4613-9030-5_7

J.F. Carnerio, J.B. Pinto, F.G. Almeida, Accurate motion control of a pneumatic linear peristaltic actuator. Actuators. 9(3), 63 (2020). https://doi.org/10.3390/act9030063

X. Yu, J. Zhang, S. Zhao, X. Yu, H. Liu, An investigation into the effect of gas adsorption on safety valve set pressure variations. Chem. Eng. Sci. 188, 170–178 (2018). https://doi.org/10.1016/j.ces.2018.05.035

D. Vnucec, N. Wetzstein, & J. Kiesbaurer, Proper Actuator Sizing for Rotary Control Valves. Valve World Magazine (2013)

D.A. Crowl, & S.A. Tipler, Sizing Pressure Relief Devices. American Institute of Chemical Engineering. 68–76. (2013). Available at: https://www.aiche.org/sites/default/files/cep/20131068.pdf [access date: 13th August 13, 2021]

J. Su, Z. Li, Z. Liu, & E. Gao, The Optimization Design of Safety Valve Used in Aircraft Based on AMESim Simulation. Guiyang, China. 19–22 June (2018)

Funding

The authors declare that no funding is associated with this study.

Author information

Authors and Affiliations

Contributions

The whole manuscript is written by a single author.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Rights and permissions

About this article

Cite this article

Sotoodeh, K. Improving integrity between valve and actuator by using pressure safety valve on control panel of pneumatic actuators. JMST Adv. 4, 13–24 (2022). https://doi.org/10.1007/s42791-022-00044-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42791-022-00044-4