Abstract

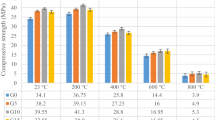

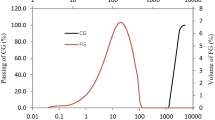

In this study, carbon black was used to manufacture electrical conductive mortar, and the carbon black and mixing water were controlled. In carbon black, secondary particles were formed with primary particles sized 100 ~ 300 nm and the electrical conductivity was measured at 19.2S/m. Mixing water content had to be increased according to the increase of carbon black content to maintain uniform flow (190 ± 5 mm) of the carbon black-incorporated mortar and the mortar strength gradually decreased with the increase of water content. For OPC mortar, electric current was measured as 0.0024A, and a heating phenomenon was not observed. On the other hand, the electric current of mortar mixed with 10% of carbon black was 0.0855A, the highest among the specimens, and the electric resistance was 163Ω∙m, which was also the highest exothermic characteristic. However, when 10wt% of carbon black was used, the mortar properties deteriorated, and thus, countermeasures for this should be further studied.

Similar content being viewed by others

References

Traffic accident analysis system data for traffic accidents by road condition (2018) (KoROAD Homepage), http://taas.koroad.or.kr/sta/acs/exs/typical.do?menuId=WEB_KMP_OVT_UAS_ASA#. (Accessed 26 August 2020)

Snow melting system by type (Hydronic and Electric), by application (Residential, commercial and municipal): global industry perspective, comprehensive analysis and forecast (Zion Market Research Report 2018. 03), (Accessed 27 August 2020)

Z. Chi, T. Yiqiu, Ye. Qing, Long-term thermal analysis of an airfield-runway snow melting system utilizing heat-pipe technology. Energy Convers Manag 186, 473–486 (2019)

K. Liu, S. Huang, F. Wang, Energy consumption and utilization rate analysis of automatically snow melting system in infrastructure by thermal simulation and melting experiments. Cold Reg Sci Technol 138, 73–83 (2017)

Christopher Y. Tuan, Sherif A. Yehia, Implementation of conductive concrete overlay for bridge deck deicing at roca, Nebraska (Civil Engineering Faculty Proceedings & Presentations, University of Nebraska at Omaha, 363–364, 2004)

A. Sassani, A. Arabzadeh, H. Ceylan, S. Kim, Carbon fiber-based electrically conductive concrete for salt-free deicing of pavements. J Clean Prod 203, 799–809 (2018)

R. Fulham-Lebrasseur, L. Sorelli, D. Conciatori, Development of electrically conductive concrete and mortars with hybrid conductive inclusions. Constr Build Mater 237, 1–10 (2020)

E. Heymsfield, A.B. Osweiler, M. Kuss, Feasibility of anti-Icing airfield pavement using conductive concrete and renewable solar energy (US Department of Transportation Report, USA, 2013), pp. 47–48

C.Y. Tuan, Implementation of conductive concrete for deicing (Roca Bridge) Nebraska Department of Transportation Research Reports (University of Nebraska-Lincoln, Lincoln, 2008), pp. 2–4

Carbon Black Properties (Wikipedia Homepage), https://ko.wikipedia.org/wiki/%EC%B9%B4%EB%B3%B8_%EB%B8%94%EB%9E%99, (Accessed 28 Aug 2020)

M. Lay, A. Rusli, Raa Khiomi Shuib, converting dead leaf biomass into activated carbon as a potential replacement for carbon black filler in rubber composites. Compos B Eng 201, 1–10 (2020)

L. Liu, H. Ma, Highly conductive graphene/carbon black screen printing inks for flexible electronics. J Colloid Interface Sci 582, 12–21 (2021)

J.A. Sánchez-González, A. Macías-García, M.F. Alexandre-Franco, V. Gómez-Serrano, Electrical conductivity of carbon blacks under compression. Carbon 43(4), 741–747 (2005)

D. Pantea, H. Darmstadt, S. Kaliaguine, C. Roy, Electrical conductivity of conductive carbon blacks: influence of surface chemistry and topology. Appl Surf Sci 217(1–4), 181–193 (2003)

I.-S. Yoon, Influence of carbonation of concrete on electrical resistivity. J Korea Inst Struct Maint Insp 18(5), 27–33 (2014)

B. Chen, Bo. Li, Y. Gao, Investigation on electrically conductive aggregates produced by incorporating carbon fiber and carbon black. Constr Build Mater 144(30), 106–114 (2017)

M. Benaicha, A. Hafidi Alaoui, O. Jalbaud, Dosage effect of superplasticizer on self-compacting concrete: correlation between rheology and strength. J Mater Res Technol 8(2), 2063–2069 (2019)

Hajar Ahmadi Moghadam, The relation between porosity, hydration degree and compressive strength of portland cement pastes in the presence of aluminium chloride additive. Constr Build Mater 250, 118884 (2020)

B. Ratner, The correlation coefficient: Its values range between +1/-1, or do they? J Targe Meas Anal Market 17, 139–142 (2009)

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jo, KS., Kim, NI., Kim, Ks. et al. A study on the electrical and physical properties of mortar incorporating carbon black. J. Korean Ceram. Soc. 58, 414–421 (2021). https://doi.org/10.1007/s43207-021-00111-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43207-021-00111-x