Abstract

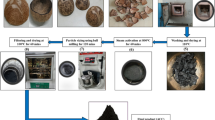

Due to the instability of the aggregate supply and demand chain, it is expected that the price of aggregate will increase, consequently increasing construction expenses. Therefore, achieving a stable aggregate supply and demand chain by developing alternative aggregates and implementing environmentally friendly aggregate collection plans that do not affect the natural ecosystem are mandatory. To address the issues of natural aggregate shortage and treating circulating fluidized bed boiler fly ash (CFBA), an artificial aggregate was manufactured by using CFBA with BFS and MT added AA, as a possible replacement for natural aggregate. The optimum artificial aggregate mix had a specific gravity of 2.47 and a water absorption rate of 4.05% after aging for 28 days. Over time, the number of gel pores in the artificial aggregate increases, and the porosity decreases. In other words, C–S–H formation in CFBA causes the size of the large pores that appear in the initial hydration to decline, attributed to the continuously generated C–S–H, and hence the number of gel pores increases, leading to a decrease in the porosity. XRD measurement of the artificial aggregate confirmed the presence of calcium silicate (C–S–H), calcium aluminosilicate (C–S–A–H), Al2O3–Fe2O3–mono, and calcium hydride. Comparing the compressive strength of ISO standard aggregate mortar and manufactured artificial aggregate mortar, the initial compressive strength of CFBA was ~ 80% of that of the standard aggregates; however, the compressive strength of CFBA increased with aging. As a result of synthesizing an artificial aggregate using self-hydric FA, it is possible to use some substitution of natural aggregate.

Similar content being viewed by others

References

S.J. Choi, Y.U. Kim, D.B. Kim, Analysis of the trends of supply and demand of aggregate in the Southeastern region of South Korea. J. Korea Inst. Build. Constr. 18(1), 324–325 (2018)

S.H. Lee, Aggregate shock and sustainable aggregate supply and supply measures. Korea Cem. Assoc. 163, 14–19 (2004)

K.W. Kang, S.M. Choi, J.M. Kim, Supply–demand forecast and development direction for aggregate. J. Korea Inst. Build. Constr. 18(1), 332–333 (2018)

J.S. Kim, J.M. Lee, D.W. Kim, T.H. Kim, A study on design characteristics of Yeosu circulating fluidized bed boiler. J. Korea Concr. Inst. 16(1), 1–7 (2011)

K.J. Mun, S.J. Kwon, Construction materials utilizing byproduct from circulating fluidized bed boiler. J. Korean Recycl. Constr. Res. Inst. 9(3), 8–12 (2014)

N. Ghazali, K. Muthusamy, S.W. Ahmad, Utilization of fly ash in construction. Mater. Sci. Eng. (2019). https://doi.org/10.1088/1757-899X/601/1/012023

Ch.S. Lim, K.G. Lee, Grinding method for increasing specific surface area of fluidized bed fly ash. J. Korean Ceram. Soc. 56(2), 153–159 (2019). https://doi.org/10.4191/kcers.2019.56.2.09

E.D. Jeong, Co-combustion characteristics of mixed coal with anthracite and bituminous in a circulating fluidized bed. J. Plant 6(2), 70–77 (2010)

N.S. Ahn, J.H. Lee, Y.H. Lee, Sulfate attack according to the quantity of composition of cement and mineral admixtures. J. Korea Inst. Build. Constr. 11(6), 547–556 (2011). https://doi.org/10.5345/JKIBC.2011.11.6.547

S.H. Hong, B.D. Lee, S.H. Han, Application of fly ash concrete in the pavement. J. Korea Concr. Inst. 20(1), 701–704 (2008)

H.S. Lim, H.S. Lee, K.H. Yang, S.J. Kwon, Quantitative evaluation of free CaO in electric furnace slag considering temperature and aging periods. J. Ceram. Process. Res. 20(1), 35–40 (2019). https://doi.org/10.36410/jcpr.2019.20.1.35

J.H. Seo, C.S. Baek, Y.J. Kim, M.K. Choi, K.H. Cho, J.W. Ahn, Study on the free CaO analysis of coal ash in the domestic circulating fluidized bed combustion using ethylene glycol method. J. Energy Eng. 26(1), 1–8 (2017). https://doi.org/10.5855/ENERGY.2017.26.1.001

H.S. Lim, H.S. Lee, An Experimental study on the free CaO quantitative analysis in the aging period of the electric arc furnace slag. Korea Concr. Inst. 26(1), 349–350 (2014)

KSM1415 “Sodium silicate liquid” Korean Standards Association: Seoul, South Korea (2017)

Y. Li, H. Lin, Z. Wang, Quantitative analysis of fly ash in hardened cement paste. Constr. Build. Mater. 153, 139–145 (2017). https://doi.org/10.1016/j.conbuildmat.2017.07.106

Q. Zeng, K. Li, T. Fen-chong, P. Dangla, Pore structure characterization of cement pastes blended with high volume fly-ash. Cem. Concr. Res. 42(1), 194–204 (2012). https://doi.org/10.1016/j.cemconres.2011.09.012

A. Terzie, L. Pezo, V. Mitic, Z. Radojevic, Artificial fly ash based aggregates properties influence on lightweight concrete performances. Ceram. Int. 41(2), 2714–2726 (2015). https://doi.org/10.1016/j.ceramint.2014.10.086

A. Kudzma, J. Skamat, R. Stonys, A. Krasnikovs, D. Kuznetsov, G. Girskas, V. Antonovic, Study on the effect of graphene oxide with low oxygen content on Portland cement-based composites. Materials 12(5), 802 (2019). https://doi.org/10.3390/ma12050802

J.H. Kim, H.S. Lee, Improvement of early strength of cement mortar containing granulated blast furnace slag using industrial byproducts. Materials 10(9), 1050 (2017). https://doi.org/10.3390/ma10091050

M.D. Andersen, H.J. Jakobsen, J. Skibsted, Characterization of white Portland cement hydration and the C-S-H structure in the presence of sodium aluminate by 27Al and 29SiMAS NMR spectroscopy. Cem. Concr. Res. 34(5), 857–868 (2004). https://doi.org/10.1016/j.cemconres.2003.10.009

S.H. Lee, G.S. Kim, Self-cementitious hydration of circulation fluidized bed combustion fly ash. J. Korean Ceram. Soc. 54(2), 128–136 (2017). https://doi.org/10.4191/kcers.2017.54.2.07

Q. Li, Xu. Hui, F. Li, Synthesis of geopolymer composites from blends of CFBC fly ash bottom ashes. Fuel 97, 366–372 (2012). https://doi.org/10.1016/j.fuel.2012.02.059

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lee, WG., Song, MS. & Kim, KN. Characteristics of artificial aggregates employing self-hydraulic fly ash. J. Korean Ceram. Soc. 58, 590–597 (2021). https://doi.org/10.1007/s43207-021-00135-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43207-021-00135-3