Abstract

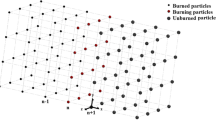

The flame structure of submicron-sized aluminum dust particles and air is investigated through a two-phase mixture in a counterflow configuration. A mathematical model is developed to estimate the premixed dust flame location and velocity in terms of the strain rate. In order to simulate combustion of dust particles, a three-zone flame structure is considered, including the preheat, reaction, and post-flame zones. The governing conservation equations for each zone are derived and solved under appropriate boundary conditions. The effects of thermophoresis and Brownian motion of fuel particles are investigated. Moreover, the particle size and polydispersity impacts on the burning rate and flame position are taken into consideration. In general, the simulation results for the flame velocity are in reasonable agreement with the experimental data available in the literature.

Similar content being viewed by others

References

M. Russo, R. Li, M. Mench, and A. van Duin “Molecular Dynamic Simulation of Aluminum–Water Reactions Using the ReaxFF Reactive Force Field,” Int. J. Hydrogen Energy 36 (10), 5828–5835 (2011).

A. Ingenito and C. Bruno, “Using Aluminum for Space Propulsion,” J. Propul. Power 20 (6) 1056–1063 (2004).

K. Jayaraman, S. R. Chakravarthy, and R. Sarathi, “Accumulation of Nano-Aluminium during Combustion of Composite Solid Propellant Mixtures,” Fiz. Goreniya Vzryva 46 (1), 26–35 (2010) [Combust., Expl., Shock Waves 46 (1), 21–29 (2010)].

C. Martin, M. Comet, F. Schnell, and J. Berthe, “Aluminum Nanopowder: A Substance to be Handled with Care,” J. Hazard. Mater. 342, 347–352 (2017).

G. Li, H. Yang, C. Yuan, and R. Eckhoff, “A Catastrophic Aluminium-Alloy Dust Explosion in China,” J. Loss Prevent. Process Ind. 39, 121–130 (2016).

S. Bernard, P. Gillard, and F. Frascati, “Ignition and Explosibility of Aluminium Alloys Used in Additive Layer Manufacturing,” J. Loss Prevent. Process Ind. 49, Part B, 888–895 (2017).

W. Wu, L. Liu, and Q. Zhang, “A New 20 L Experimental Vessel for Dust Explosion and Measurement of Local Concentration,” J. Loss Prevent. Process Ind. 49, Part B, 299–309 (2017).

E. L. Dreizin, “Experimental Study of Stages in Aluminium Particle Combustion in Air,” Combust. Flame 105 (4), 541–556 (1996).

M. W. Beckstead, A Summary of Aluminum Combustion (Brigham Young Univ., Provo, 2004).

M. Filippo, S. Dossi, C. Paravan, et al., “Activated Aluminum Powders for Space Propulsion,” Powder Technol. 270, Part A, 46–52 (2015).

D. S. Sundaram, V. Yang, and V. E. Zarko, “Combustion of Nano Aluminum Particles (Review),” Fiz. Goreniya Vzryva 51 (2), 37–63 (2015) [Combust., Expl., Shock Waves 51 (2), 173–196 (2016)].

Q. Li, K. Wang, Y. Zheng, et al., “Explosion Severity of Micro-Sized Aluminum Dust and Its Flame Propagation Properties in 20 L Spherical Vessel,” Powder Technol. 301, 1299–1308 (2016).

M. Bidabadi, M. Mohammadi, A. K. Poorfar, et al., “Modeling Combustion of Aluminum Dust Cloud in Media with Spatially Discrete Sources,” Heat Mass Transfer. 51 (6), 837–845 (2015).

R. Yetter, G. Risha, and S. Son, “Metal Particle Combustion and Nanotechnology,” Proc. Combust. Inst. 32 (2), 1819–1838 (2009).

F. Delogu, “Thermodynamics on the Nanoscale,” J. Phys. Chem. B 109 (46), 21938–21941 (2005).

Y. Kwon, A. Gromov, A. Ilyin, and E. Popenko, “The Mechanism of Combustion of Superfine Aluminum Powders,” Combust. Flame 133 (4), 385–391 (2003).

M. Zachariah, M. Aquino, R. Shull, and E. Steel, “Formation of Superparamagnetic Nanocomposites from Vapor Phase Condensation in a Flame,” Nanostructured Mater. 5, (4), 383–392 (1995).

Y. Huang, G. A. Risha, V. Yang, and R. A. Yetter, “Combustion of Bimodal Nano/Micron-Sized Aluminum Particle Dust in Air,” Proc. Combust. Inst. 31 (2), 2001–2009 (2007).

D. Beck and R. Siegel, “The Dissociative Adsorption of Hydrogen Sulfide over Nanophase Titanium Dioxide,” J. Mater. Res. 7 (10), 2840–2845 (1992).

Y. Huang, G. A. Risha, V. Yang, and R. A. Yetter, “Effect of Particle Size on Combustion of Aluminum Particle Dust in Air,” Combust. Flame 156 (1), 5–13 (2009).

P. Bocanegra, C. Chauveau, and I. G¨okalp, “Experimental Studies on the Burning of Coated and Uncoated Micro and Nano-Sized Aluminium Particles,” Aerosp. Sci. Technol. 11 (1), 33–38 (2007).

G. Risha, S. Son, R. Yetter, and V. Yang, “Combustion of Nano-Aluminum and Liquid Water,” Proc. Combust. Inst. 31 (2), 2029–2036 (2007).

P. Keblinski, S. Phillpot, and S. Choi, “Mechanisms of Heat Flow in Suspensions of Nano-Sized Particles (Nanofluids),” Int. J. Heat Mass Transfer. 45 (4), 855–863 (2002).

A. Toda, H. Ohnishi, R. Dobashi, and T. Hirano, “Experimental Study on the Relation between Ther-mophoresis and Size of Aerosol Particles,” Int. J. Heat Mass Transfer. 41 (17), 2710–2713 (1998).

M. Bidabadi, M. Ramezanpour, M. Mohammadi, and J. Fereidooni, “The Effect of Thermophoresis on Flame Propagation in Nano-Aluminum and Water Mixtures,” Period. Polytech. Chem. Eng. 60 (3), 157–164 (2016).

H. Guo, Y. Ju, K. Maruta, et al., “Radiation Extinction Limit of Counterflow Premixed Lean Methane–Air Flames,” Combust. Flame 109 (4), 636–646 (1997).

M. Bidabadi, M. Vakilabadi, A. Poorfar, et al., “Mathematical Modeling of Premixed Counterflow Combustion of Organic Dust Cloud,” Renew. Energy 92, 376–384 (2016).

P. Julien, S. Whiteley, M. Soo, and S. Goroshin, “Flame Speed Measurements in Aluminum Suspensions Using a Counterflow Burner,” Proc. Combust. Inst. 36 (2) 2291–2298 (2017).

Y. Sun, R. Sun, B. Zhu, et al., “Combustion Characteristics of Nano-Aluminum Cloud in Different Atmospheres,” Ind. Eng. Chem. Res. 57 (1) 129–138 (2018).

W. Gao, X. Zhang, D. Zhang, et al., “Flame Propagation Behaviours in Nano-Metal Dust Explosions,” Powder Technol. 321, 154–162 (2017).

M. Mohammadi, M. Bidabadi, and H. Khalili, “Modeling Counterflow Combustion of Dust Particle Cloud in Heterogeneous Media,” J. Energy Eng. 143 (2), (2017).

S. M. Murshed and C. A. de Castro, “Predicting the Thermal Conductivity of Nanofluids—Effect of Brownian Motion of Nanoparticles,” J. Nanofluids 1 (2) 99–114 (2012).

J. Sun, R. Dobashi, and T. Hirano, “Combustion Behavior of Iron Particles Suspended in Air,” Combust. Sci. Technol. 150 (1–6), 99–114 (2000).

M. Bidabadi, M. Mohebbi, A. K. Poorfar, et al., “Modeling Quenching Distance and Flame Propagation Speed through an Iron Dust Cloud with Spatially Random Distribution of Particles,” J. Loss Prevent. Process Ind. 43, 138–146 (2016).

T. L. Bergman and F. P. Incropera, Fundamentals of Heat and Mass Transfer (John Wiley and Sons, 2011).

M. Bidabadi, S. Zadsirjan, and S. Mostafavi, “Propagation and Extinction of Dust Flames in Narrow Channels,” J. Loss Prevent. Process Ind. 26 (1), 172–176 (2013).

T. A. Marino, Numerical Analysis to Study the Effects of Solid Fuel Particle Characteristics on Ignition, Burning, and Radiative Emission (The George Washington Univ., 2008).

E. Loth, T. O’Brien, M. Syamlal, and M. Cantero, “Effective Diameter for Group Motion of Polydisperse Particle Mixtures,” Powder Technol. 142 (2/3), 209–218 (2004).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © H. Khalili, S.A. Madani, M. Mohammadi, A.K. Poorfar, M. Bidabadi, P. Pendleton.

Rights and permissions

About this article

Cite this article

Khalili, H., Madani, S.A., Mohammadi, M. et al. Mathematical Modeling of Premixed Counterflow Combustion of a Submicron-Sized Aluminum Dust Cloud. Combust Explos Shock Waves 55, 65–73 (2019). https://doi.org/10.1134/S0010508219010076

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0010508219010076