Abstract

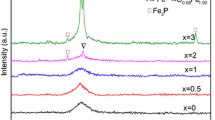

Nanocrystalline alloys (Fe0.6Co0.4)86Hf7B6Cu1 and (Fe0.7Co0.3)88Hf7B4Cu1 have been investigated to obtain materials with improved thermal stability and new features. In order to make the alloys produced by melt quenching on a rotating wheel nanocrystalline, they have been subjected to heat (HT) and thermomechanical (TMechT) treatments. The effect of HT and TMechT conditions on the magnetic properties, thermal stability, and structure of the alloys has been studied. The optimal HT conditions for obtaining the minimum values of the coercive force (H c) in the alloys have been determined. It is shown that TMechT of the alloys leads to the induced longitudinal magnetic anisotropy with the axis of easy magnetization along the long side of the ribbon in the studied temperature range of 520–620°C. It has been established that the alloys (Fe0.6Co0.4)86Hf7B6Cu1 and (Fe0.7Co0.3)88Hf7B4Cu1 are thermally unstable at temperatures above 500°C.

Similar content being viewed by others

References

T. Kulik, J. Ferenc, A. Kolano-Burian, X. B. Liang, and M. Kowalczyk, “Magnetically Soft Nanomaterials for High-Temperature Applications,” J. Alloys Compd. 434–435, 623–627 (2007).

Zs. Gercsi, F. Mazaleyrat, and L. K. Varga, “High-Temperature Soft Magnetic Properties of Co-Doped Nanocrystalline Alloys,” J. Magn. Magn. Mater. 302, 454–458 (2006).

X. B. Liang, T. Kulik, J. Ferenc, M. Kowalcyk, G. Vlasak, W. S. Sun, B. and S. Xu, “Influence of Structure on Coercivity in Nanocrystalline (Fe1 − x Cox)86Hf7B6Cu1 Alloys,” Physica B: Condens. Matter 370, 151–157 (2005).

N. M. Kleinerman, V. V. Serikov, V. A. Lukshina, N. V. Dmitrieva, and A. P. Potapov, “Nanocrystalline Alloy Fe73.5CuNb3Si13.5B9, Its Structure and Magnetic Properties: I. The Investigation of the Process of Crystallization from the Amorphous State under the Effect of Various External Factors,” Phys. Met. Metallogr. 91, 578–582 (2001).

X. B. Liang, T. Kulik, J. Ferenc, T. Erenc-Stdziak, B. S. Xu, A. Grabias, and M. Kopcewicyz, “Mössbauer Study on Amorphous and Nanocrystalline (Fe1 − x Cox)86Hf7B6Cu1 Alloys,” Mater. Charact. 58, 143–147 (2007).

H. Iwanabe, B. Lu, M. E. McHenry, and D. E. Laughlin, “Thermal Stability of the Nanocrystalline Fe-Co-Hf-B-Cu Alloy,” J. Appl. Phys. 85, 4424–4426 (1999).

J. Ference, J. Latuch, and T. Kulik, “Magnetic Properties of Partially Crystallised Fe-Co-Hf-Zr-B-Cu Alloys,” J. Magn. Magn. Mater. 272–276, 1469–1470 (2004).

T. Kulik, J. Ferenc, A. Kolano-Burian, X. B. Liang, and M. Kowalczyk, “Magnetically Soft Nanomaterials for High-Temperature Applications,” Mater. Sci. Eng., A 449–451, 397–400 (2007).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © N.V. Dmitrieva, V.A. Lukshina, E.G. Volkova, A.P. Potapov, V.S. Gaviko, B.N. Filippov, 2013, published in Fizika Metallov i Metallovedenie, 2013, Vol. 114, No. 2, pp. 144–152.

Rights and permissions

About this article

Cite this article

Dmitrieva, N.V., Lukshina, V.A., Volkova, E.G. et al. Fe- and co-based nanocrystalline soft magnetic alloys modified with Hf, Mo, and Zr: Magnetic properties, thermal stability, and structure. Alloys (Fe0.6Co0.4)86Hf7B6Cu1 and (Fe0.7Co0.3)88Hf7B4Cu1 . Phys. Metals Metallogr. 114, 129–137 (2013). https://doi.org/10.1134/S0031918X13020051

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X13020051