Abstract

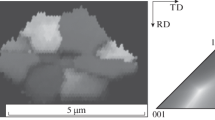

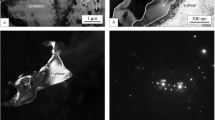

Methods of optical and electron microscopies were used to study the structure of particles of niobium carbide in a cast refractory Fe–Cr–Ni–C alloy modified by Nb and Ti. Particles of niobium carbide in the structure of the cast alloy are predominantly multiphase polycrystalline clusters that are inhomogeneous in the chemical composition and crystal structure. The misorientation angle between individual crystals that compose the carbide particles is 30°–60°. The polycrystalline character of carbides is probably associated with significant thermal stresses that arise at the interphase boundaries in the structure of the alloy upon the primary cooling of the ingot. To explain the polymorphism of the cluster of niobium carbide, a further analysis of the structural and geometrical crystallography is required.

Similar content being viewed by others

References

M. Garbiak, W. Jasinski, and B. Piekarski, “Materials for reformer furnace tubes. History of evolution,” Arch. Foundry Eng. 11 (SI 2), 47–52 (2011).

L. Bonaccorsi, E. Guglielmino, E. Pino, C. Servetto, and A. Sili, “Damage analysis in Fe–Cr–Ni centrifugally cast alloy tubes for reforming furnaces,” Eng. Fail. Anal. 36, 65–74 (2014).

M. N. Ilman, M. Prihajatno, and Kusmono, “Analysis of material degradation and life assessment of 25Cr–38Ni–Mo–Ti wrought alloy steel (HPM) for cracking tubes in an ethylene plant,” Eng. Fail. Anal. 42, 100–108 (2014).

H. M. Tawancy, A. Ul-Hamid, A. I. Mohammed, and N. M. Abbas, “Effect of materials selection and design on the performance of an engineering product—An example from petrochemical industry,” Mater. Des. 28, 686–703 (2007).

A. A. Kaya, P. Krauklis, and D. J. Young, “Microstructure of HK40 alloy after high-temperature service in oxidizing/carburizing environment: I. Oxidation phenomena and propagation of a crack,” Mater. Charact. 49, 11–21 (2002).

A. A. Kaya, “Microstructure of HK40 alloy after hightemperature service in oxidizing/carburizing environment: II. Carburization and carbide transformations,” Mater. Charact. 49, 23–34 (2002).

L. H. de Almeida, A. F. Ribeiro, and I. le May, “Microstructural characterization of modified 25Cr–35Ni centrifugally cast steel furnace tubes,” Mater. Charact. 49, 219–229 (2003).

E. A. Kenik, P. J. Maziasz, R. W. Swindeman, J. Cervenka, and D. May, “Structure and phase stability in cast modified-HP austenite after long-term ageing,” Scr. Mater. 49, 117–122 (2003).

A. I. Rudskoi, A. S. Oryshchenko, S. Yu. Kondrat’ev, G. P. Anastasiadi, M. D. Fuks, and S. N. Petrov, “Special features of structure and long-term strength of cast refractory alloy 45Kh26N33S2B2,” Met. Sci. Heat Treat. 55, 209–215 (2013).

A. I. Rudskoi, G. P. Anastasiadi, S. Yu. Kondrat’ev, A. S. Oryshchenko, and M. D. Fuks, “Effect of electron factor (number of electron holes) on kinetics of nucleation, growth, and dissolution of phases during long-term high-temperature holdings of 0.45C–26Cr–33Ni–2Si–2Nb superalloy,” Phys. Met. Metallogr. 115, 1–11 (2014).

I. A. Sustaita-Torres, S. Haro-Rodrigues, M. P. Guerrero-Mata, M. de la Garza, E. Valdes, F. Deschaux-Beaume, and R. Colas, “Aging of cast 35Cr–45Ni heat resistant alloy,” Mater. Chem. Phys., 133, 1018–1023 (2012). http://dx.doi.org/ doi 10.1016/j.matchemphys. 2012.02.010

L. S. Monobe and C. G. Schon, “Microstructural and fractographic investigation of a centrifugally cast 20Cr32Ni + Nb alloy tube in the ‘as cast’ and aged states,” J. Mater. Res. Technol. 2, 195–201 (2013).

W. Z. Wang, F. Z. Xuan, Z. D. Wang, and C. J. Liu, “Effect of overheating temperature on the microstructure and creep behavior of HP40Nb alloy,” Mater. Design 32, 4010–4016 (2011).

S. Borjali, S. R. Allahkaram, and H. Khosravi, “Effects of working temperature and carbon diffusion on the microstructure of high pressure heat-resistant stainless steel tubes used in pyrolysis furnaces during service condition,” Mater. Design 34, 65–73 (2012).

A. I. Rudskoi, A. S. Oryshchenko, S. Yu. Kondrat’ev, G. P. Anastasiadi, and M. D. Fuks, “Mechanisms and kinetics of phase transformations in refractory alloy 45Kh26N33S2B2 in long-term high-temperature holds. Part 1,” Met. Sci. Heat Treat. 56, 3–8 (2014).

A. I. Rudskoi, S. Yu. Kondrat’ev, G. P. Anastasiadi, A. S. Oryshchenko, and M. D. Fuks, “Mechanisms and kinetics of phase transformations in refractory alloy 45Kh26N33S2B2 under long-term high-temperature holds. Part 2,” Met. Sci. Heat Treat. 56, 124–130 (2014).

A. I. Rudskoi, S. Yu. Kondrat’ev, G. P. Anastasiadi, A. S. Oryshchenko, M. D. Fuks, S. N. Petrov, “Transformation of the structure of refractory alloy 0.45C–26Cr–33Ni–2Si–2Nb during a long-term high-temperature hold,” Met. Sci. Heat Treat. 55, 517–525 (2014).

B. Piekarski, “Effect of Nb and Ti additions on microstructure and identification of precipitates in stabilized Ni–Cr cast austenitic steels,” Mater. Charact. 47, 181–186 (2001).

T. L. Silveira and I. le May, “Niobium additions in HP heat-resistant cast stainless steels,” Mater. Charact. 29, 387–396 (1992).

K. G. Buchanan and M. V. Kral, “Crystallography and morphology of niobium carbide in as-cast HP-niobium reformer tubes,” Metall. Mater. Trans. A 43, 1760–1769 (2012).

K. G. Buchanan, M. V. Kral, and C. M. Bishop, “Crystallography and morphology of MC carbides in niobium-titanium modified as-cast HP alloys,” Metall. Mater. Trans. A 45, 3373–3385 (2014).

F. C. Nunes, L. H. De Almeida, J. Dille, and J.-L. Delplancke, and I. le May, “Microstructural changes caused by yttrium addition to NbTi-modified centrifugally cast HP-type stainless steels,” Mater. Charact. 58, 132–142 (2007).

S. Yu. Kondrat’ev, A. V. Ptashnik, G. P. Anastasiadi, and S. N. Petrov, “Analysis of transformations of carbide phases in alloy 25Cr35Ni by the method of quantitative electron microscopy,” Met. Sci. Heat Treat. 57, 402–409 (2015).

Y. Jingbo, G. Yimin, Y. Fang, Y. Caiying, Y. Zhaozhong, Y. Dawei, and M. Shengqiang, “Effect of tungsten on the microstructure evolution and mechanical properties of yttrium modified HP40Nb alloy,” Mater. Sci. Eng., A 529, 361–369 (2011).

T. Sourmail, “Precipitates in creep resistant austenitic stainless steels,” Mater. Sci. Technol. 17, 1–14 (2001).

V. V. Rybin, A. S. Rubtsov, and E. V. Nesterova, “Method of single reflections and its application for electron-microscopical analysis of dispersed phases,” Zavod. Lab. no. 5, 16–21 (1982).

I. G. Rodionova, A. I. Zaitsev, N. G. Shaposhnikov, I. N. Chirkina, A. M. Pokrovskii, A. A. Nemtinov, P. A. Mishnev, and V. V. Kuznetsov, “Effect of chemical content and production parameters on formation of nanostructural component and complex of highstrength low-doped structural steel properties,” Metallurgiya, No. 6, 33–39 (2010).

Z. Mao, W. Chen, D. N. Seidman, and C. Wolverton, “First-principles study of the nucleation and stability of ordered precipitates in ternary Al–Sc–Li alloys,” Acta Mater. 59, 3012–3023 (2011).

C. Monachon, M. E. Krug, D. N. Seidman, and D. C. Dunand, “Chemistry and structure of core/double-shell nanoscale precipitates in Al–6.5Li–0.07Sc–0.02Yb (At. %),” Acta Mater. 59, 3398–3409 (2011).

A. Formenti, A. Eliasson, A. Mitchell, and H. Fredriksson, “Solidification sequence and carbide precipitation in Ni-base superalloys In718, In625 and In939,” High Temp. Mater. Processes 24, 239–258 (2005).

F. C. Nunes, J. Dille, J. -L. Delplancke, and L. H. de Almeida, “Yttrium addition to heat-resistant cast stainless steel,” Scr. Mater. 54, 1553–1556 (2006).

T. J. Konno, E. Miura, A. Tanaka, and Sh. Hanada, “A TEM study on the semicoherent precipitates in a Nb–19% Mo alloy,” Acta Mater. 53, 1783–1789 (2005).

J. Billingham, P. S. Bell, and M. H. Lewis, “Vacancy short-range order in substoichiometric transition metal carbides and nitrides with the NaCl structure. I. Electron diffraction studies of short-range ordered compounds,” Acta Crystallogr., Sect. A: Found. Crystallogr. 28, 602–606 (1972).

J. P. Landesman, A. N. Christensen, C. H. De Novion, N. Lorenzelli, and P. Convert, “Order–disorder transition and structure of the ordered vacancy compound Nb6C5: Powder neutron diffraction studies,” J. Phys. C: Solid State Phys. 18, 809–824 (1985).

R. Kesri and S. Hamar-Thibault, “Structures ordonnees a longue distance dans les carbures MC dans les fonts,” Acta. Metall. 36, 149–166 (1988).

A. I. Gusev and A. A. Rempel, “Order–disorder phase transition channel in niobium carbide,” Phys. Stat. Sol. A: Appl. Mater. Sci. 93, 71–80 (1986).

Steel Castings Handbook. Supplement 9. High Alloy Data Sheets. Heat Series. (Steel Founder’s Society of America, Ohio, 2004).

R. A. P. Ibanez, G. D. de Almeida Soares, and L. H. de Almeida, and I. Le May, “Effects of Si content on the microstructure of modified-HP austenitic steels,” Mater. Charact. 30, 243–249 (1993).

F. G. Caballero, P. Imizcoz, V. Lopez, L. F. Alvarez, and C. de Andres, “Use of titanium and zirconium in centrifugally cast heat resistant steel,” Mater. Sci. Technol. 23, 528–534 (2007).

Wm. F. Brizes, L. H. Cadoff, and J. M. Tobin, “Carbon diffusion in the carbides of niobium,” J. Nucl. Mater. 20, 57–67 (1966).

A. Talis and V. Kraposhin, “Finite noncrystallographic groups, 11-vertex triangulated clusters, and polymorphic transformations in metals,” Acta Crystall. A 70, 616–625 (2014).

S. Yu. Kondrat’ev, V. S. Kraposhin, G. P. Anastasiadi, and A. L. Talis, “Experimental observation and crystallographic description of M7C3 carbide transformation in Fe–Cr–Ni–C HP type alloy,” Acta Mater. 100, 275–281 (2015).

V. S. Kraposhin, A. L. Talis, E. D. Demina, and A. I. Zaitsev, “Crystal geometry mechanism of intergrowth of spinel and manganese sulfide into a complex nonmetallic inclusion,” Met. Sci. Heat Treat. 57, 371–378 (2015).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © S.Yu. Kondrat’ev, E.V. Svyatisheva, G.P. Anastasiadi, S.N. Petrov, 2017, published in Fizika Metallov i Metallovedenie, 2017, Vol. 118, No. 7, pp. 693–704.

Rights and permissions

About this article

Cite this article

Kondrat’ev, S.Y., Svyatisheva, E.V., Anastasiadi, G.P. et al. Structure of strengthening particles of niobium carbide in Fe–Cr–Ni cast refractory alloys. Phys. Metals Metallogr. 118, 659–670 (2017). https://doi.org/10.1134/S0031918X17070055

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X17070055