Abstract

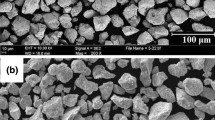

The effect of gaseous sulfocarbonitriding on the wear resistance of porous Ni3Al-based gas-thermal coatings is studied. An empirical model is developed to describe the wear kinetics of the coatings, and it takes into account the character of changing the wear parameters in time.

Similar content being viewed by others

REFERENCES

V. I. Kalita and D. I. Komlev, Plasma Coatings with Nanocrystalline and Amorphous Structure (Lider, Moscow, 2008).

Technologies of Structural Nanostructured Materials and Coatings, Ed. by P. A. Vityaz’ and K. A. Solntsev (Belarus. Navuka, Minsk, 2011).

A. Y. Ivannikov, V. I. Kalita, D. I. Komlev, A. A. Radyuk, V. P. Bagmutov, I. N. Zakharov, and S. N. Parshev, “The effect of electromechanical treatment on structure and properties of plasma sprayed Ni–20Cr coating,” J. Alloys Compd. 655, 11–20 (2016).

A. A. Fomin, V. I. Kalita, V. A. Koshuro, D. I. Komlev, M. A. Fomina, I. S. Egorov, I. V. Rodionov, A. A. Radyuk, A. Yu. Ivannikov, A. Aman, A. Yu. Oseev, and Z. Hirsh, “Structure and microhardness of titanium coatings on implants after induction-heat treatment,” Perspekt. Mater., No. 12, 25–37 (2016).

M. A. Belotserkovskii, A. N. Grigorchik, and V. A. Kukareko, “Concentration inhomogeneity of nitrided layers in gas-thermal coatings subjected to ion-beam treatment,” Aktual. Problemy Mashinostr. 4 (1), 93–98 (2017).

A. N. Grigorchik, V. A. Kukareko, N. N. Popok, and Ya. S. Sachivko, “Influence of thermochemical treatment on the structure and wear resistance of hypersonic gas-thermal coatings made of SV-08G2S steel,” Aktual. Vopr. Mashinoved. 4, 370–374 (2015).

V. A. Kukareko, A. V. Belyi, M. A. Belotserkovskii, and A. N. Grigorchik, “Influence of ion-beam nitriding on the structural-phase state and tribotechnical properties of economical gas-thermal coatings made of wire steels of various classes,” Trenie Iznos 34 (6), 621–627 (2013).

O. G. Devoino, A. P. Pilipchuk, and S. Loche, “Formation of functional gradient coatings by the combined method of gas-thermal sputtering and laser treatment,” Aktual. Vopr. Mashinoved. 8, 277–282 (2019).

A. N. Grigorchik, V. A. Kukareko, and M. A. Belotserkovskii, “Structural and phase state and wear resistance of gas-thermal coating made of high-chromium steel 40Kh13 subjected to various types of strengthening surface treatment,” Aktual. Vopr. Mashinoved. 3, 354–357 (2014).

K. V. Zaitsev and R. R. Fazleev, “Application of ultrasound in coating application,” Sovr. Probl. Nauki Obrazov., No. 5 (2014). http://www.science-education.ru/ru/article/view?id=14842. Cited March 22, 2020.

V. N. Glushchenko, L. P. Dmitrieva, and E. I. Frumkin, “Wear resistance of nitrided powder materials,” Metalloved. Term. Obrab. Met., No. 9, 36–37 (1990).

V. D. Hegai, “Application of sulfocyanided gas-thermal coatings for friction discs,” in Repair of River Vessels (LIVT, Leningrad, 1990), pp. 112–117.

S. G. Chulkin, “Influence of sulfocarbonitriding on the wear resistance of porous gas-thermal coatings,” Trenie, Iznos, Smazka 2 (4), 7 (2000).

S. G. Chulkin, “Wear resistance as a property of tribounit materials and operating conditions,” Reshetnev. Chteniya 1, 319–321 (2014).

P. Stankevich, V. Mironovs, E. Visilyeva, A. Breki, and O. Tolochko, “The possibility of modifying the elements of the bearing assembly with nanoparticles in order to reduce the friction coefficient,” IOP Conf. Ser.: Mater. Sci. Eng., 012084 (1–5) (2017).

S. E. Alexandrov, K. S. Tyurikov, and A. D. Breki, “Low-temperature plasma-chemical deposition of nanocomposite antifriction molybdenum disulfide (filler)-silicon oxide (matrix) coatings,” Russ. J. Appl. Chem. 90 (11), 1753–1759 (2017).

A. Breki and M. Nosonovsky, “Einstein’s viscosity equation for nanolubricated friction,” Langmuir 43 (34), 12968–12973 (2018).

A. D. Breki, A. E. Gvozdev, A. G. Kolmakov, and N. N. Sergeev, “Investigation of the friction of turning of ShKh15 steel on R6M5 and 10R6M5-MP steels using mathematical modeling,” Materialoved., No. 12, 40–45 (2018).

Funding

This work was carried out in terms of state assignments no. 11.6682.2017/8.9 and 075-00947-20-00 of the Ministry of Education and Science of the Russian Federation.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by K. Shakhlevich

Rights and permissions

About this article

Cite this article

Breki, A.D., Chulkin, S.G., Gvozdev, A.E. et al. Empirical Mathematical Model for the Wear Kinetics of Porous Gas-Thermal Coatings. Russ. Metall. 2021, 496–500 (2021). https://doi.org/10.1134/S0036029521040078

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029521040078