Abstract

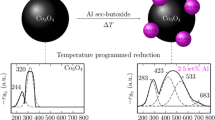

The kinetics of dissolution of the commercial powdered Co3O4 cobalt oxide in an aqueous H2SO4 solution of various concentrations is experimentally studied. Electron microscopy and X-ray diffraction analysis are used to study the effect of the initial state of the surface structure of the cobalt oxide on the kinetic characteristics of dissolution. The shape and sizes of Co3O4 particles and the character of their surface distribution are determined. The ICDD powder material database is used to identify the structure of the oxide samples, and the Co3O4 oxide is found to be represented by the α form of cubic symmetry. Kinetic curves are constructed and the kinetic parameters of the process are calculated. The results obtained can serve as a contribution to the generalization of the experimental material accumulated to determine the laws of dissolution of the oxide phases of cobalt and other transition metals in acid electrolytes of various compositions.

Similar content being viewed by others

REFERENCES

V. A. Potylitsin, “Production and consumption of cobalt,” Tsvetn. Met., No. 1, 6–10 (2015).

A. I. Yuryev, O. V. Nosova, and V. B. Fomichev, Technology of Cobalt Production (Norilsk Indeustr. Inst., Norilsk, 2014).

A. G. Kasikov, “Research and development of IKhTREMS KNTs RAN in the field of chemistry and technology of cobalt,” Vestn. Kol’sk. NTs RAN, No. 3, 54–63 (2015).

A. G. Kasikov, L. V. D’yakova, and O. A. Khomchenko, “Implementation of the extraction technology of new cobalt production in AO Kola GMK,” Tsvetn. Met., No. 1, 14–19 (2018).

E. V. Chernousenko, G. V. Mitrofanova, I. N. Vishnyakova, and Yu. S. Kameneva, “Flotation and magnetic methods for separating nonferrous metals from poor technical raw materials,” Tsvetn. Met., No. 2, 11–16 (2019).

Nickel and Cobalt Production. Information and Technical Handbook on the Best and Available Technologies (Byuro NDT, Moscow, 2016).

P. A. Rozin and A. V. Akimov, “Application of hard magnetic materials in electric machines on vehicles,” Izv. MGTU MAMI 1 (2), 12–18 (2014).

T. A. Nenastina, M. A. Glushkova, and Yu. K. Gapon, “Ecological aspects of the formation of multicomponent coatings with cobalt alloys,” Vestn. Kharkiv. Nats. Avtomob.-Dorozhn. Univ., No. 70, 69–75 (2015).

A. I. Fatkhutdinov, D. A. Ibragimova, I. A. Ivanova, Z. F. Sharafieva, and A. A. Mukhametzyanova, “Catalysts in the processes of hydrocracking of residual raw materials,” Vestn. Kazan Tekhnol. Univ. 20 (7), 74–77 (2017).

L. B. Pavlovich and N. A. Shalaeva, “Catalytic purification of the emissions of the air vents of cake and by-product process,” Vestn. Sib. Gos. Industr. Univ., No. 2, 54–59 (2017).

A. A. Mikhailovskii and N. A. Terent’yeva, “GTL production of synthetic hydrocarbons from natural gas,” Vestn. Kazan Tekhnol. Univ. 18 (23), 31–36 (2015).

E. N. Vinogradova, “Investigation of catalysts based on nickel, copper and cobalt oxides in the process of methane oxidation,” Uspekhi Khim. Khim. Tekhnol. 23 (2), 43–47 (2009).

Chika Hayashi, Takuo Hayashi, and Tohru Yamada, “Cobalt-catalyzed reductive carboxylation of α, β-unsaturated compounds with carbon dioxide,” Bull. Chem. Soc. Jap. 88 (6), (2015). https://doi.org/10.1246/bcsj.20150043

Jin-Peng Yu, Zeng-Hui Han, Xiao-Hong Hu, Hui Zhang, Yun-Hong Zhou, and Xiang-Jiang Liu, “The investigation of LiCo1 – xSBxO2 as a promising cathode material for lithium-ion batteries,” Electrochim. Acta 121, 301–306 (2014).

V. A. Tarnopolskii, “Some trends in the improvement of cathode materials for lithium-ion batteries,” Electrokhim. Energetika 8 (1), 3–11 (2008).

A. A. Novakova, A. V. Dolzhikova, N. V. Shatrova, and V. V. Levina, “Structure of the metallic cobalt particles formed during the reduction of Co3O4 microspheres synthesized by pyrolysis of ultrasonic aerosols,” Vestn. MGU, Ser. 3: Fizika, Astronomiya, No. 4, 22–26 (2017).

S. V. Cherepanova, O. A. Bulavchenko, and S. V. Tsybulya, “Structure of nanocrystalline metallic cobalt particles formed during reduction from Co3O4 oxides,” Zh. Strukt. Khim. 49 (3), 512–516 (2008).

Z. Marchenko, Photometric Determination of Elements (Mir, Moscow, 1971).

A Comprehensive Database of Powder Diffraction Patterns—ICDD (2019).

E. A. Eliseeva, S. L. Berezina, V. S. Boldyrev, and Yu. M. Averina, “Influence of the morphology of Co2O3 particles on the dissolution kinetics in electrolytes,” Tsvetn. Met., No. 11, 14–18 (2020).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by K. Shakhlevich

Rights and permissions

About this article

Cite this article

Eliseeva, E.A., Berezina, S.L., Gorichev, I.G. et al. Effect of the Surface Structure of the Co3O4 Oxide on the Dissolution Kinetics in an Acid Electrolyte. Russ. Metall. 2022, 42–47 (2022). https://doi.org/10.1134/S0036029522010062

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029522010062