Abstract

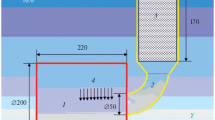

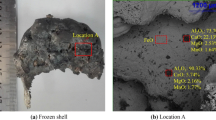

The mathematical apparatus of a model developed to describe the distribution of dispersed particles during centrifugal casting is described. The distribution of dispersed tungsten carbide particles in grade 20 steel during centrifugal casting on a centrifugal casting machine with a vertical axis of rotation is investigated. As a result of numerical simulation, the presence of a gradient distribution of dispersed particles is found and the limiting concentration of particles (0.008–0.013 g/cm3) is determined. The distribution of dispersed particles over the solidifying workpiece volume to be simulated is obtained.

Similar content being viewed by others

REFERENCES

I. V. Chumanov, N. T. Kareva, V. I. Chumanov, et al., “Study and analysis of the structural constituents of billets hardened by fine-grained particles and formed by centrifugal casting,” Russ. Metall. (Metally) 2012 (6), 539–541 (2012).

I. V. Chumanov, A. N. Anikeev, and V. I. Chumanov, “Preparation of precipitation-strengthened hollow billets for rotary dispersers,” Metallurgist 55 (5–6), 439–443 (2011).

S. El-Hadad, H. Sato, E. Miura-Fujiwara, et al., “Fabrication of Al/Al3Ti functionally graded materials by reaction centrifugal mixed-powder method,” Japan. J. Appl. Phys. 50 (1), р. 2, #01AJ02 (2011).

Y. Watanabe, O. Inaguma, H. Sato, et al., “A novel fabrication method for functionally graded materials under centrifugal force: the centrifugal mixed-powder method,” Materials 2 (4), 2510–2525 (2009).

M. Barron, D. Medina, J. Reyes, et al., “Analysis of molten metal distribution in the mold of a horizontal centrifugal casting,” Open J. Appl. Sci. 10 (7), 444–454 (2020).

A. Ashirbekov, A. Abilgaziyev, S. Kurokawa, M. H. Ali, et al., “Modeling of functionally graded materials using thermal loads,” J. Eng. Sci. Technol. 15 (3), 1719–1730 (2020).

R. Ambigai, S. Prabhu, et al., “Analyzing the mechanical properties and characterization of aluminum (ADC-14) based functionally graded materials (FGM),” Silicon (2021). https://doi.org/10.1007/s12633-021-01050-2

Y. Wu, Z. Liu, F. Wang, B. Li, Y. Gan et al., “Experimental investigation of trajectories, velocities and size distributions of bubbles in a continuous-casting mold,” Powder Technol. 387 (2), 325–335 (2021).

W. Ebhota, A. Karun, F. Inambao, et al., “Centrifugal casting technique baseline knowledge, applications, and processing parameters: overview,” Int. J. Mater. Res. 107 (10), 1–10 (2016).

I. A. Alekseev, A. N. Anikeev, and V. V. Sedukhin, “Mathematical modeling of the motion of dispersed particles in a liquid metal flow and the prediction of their localization during centrifugal casting,” Vestn. YuUrGU. Ser. Metallurgiya, No. 3 (20), 21–32 (2020).

A. N. Anikeev, I. V. Chumanov, I. A. Alekseev, and V. V. Sedukhin, “Computer modeling of the distribution of dispersed particles over the cross-section of dispersed reinforced metal materials,” Izv. Vyssh. Uchebn. Zaved., Chern. Metall., No. 8 (63), 657–664 (2020).

I. V. Chumanov and A. N. Anikeev, “Wettability of tungsten carbide by a metallic melt. Part I,” Elektrometallurgiya, No. 1, 32–34 (2014).

I. V. Chumanov and A. N. Anikeev, “Wettability of tungsten carbide by a metallic melt. Part II,” Elektrometallurgiya, No. 2, 34–35 (2014).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by K. Shakhlevich

Rights and permissions

About this article

Cite this article

Chumanov, I.V., Anikeev, A.N., Novoselov, A.V. et al. Numerical Simulation of the Distribution of Hardening Dispersed Particles during Centrifugal Casting on a Machine with a Vertical Axis of Rotation. Russ. Metall. 2022, 593–597 (2022). https://doi.org/10.1134/S0036029522060076

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029522060076