Abstract

An experimental investigation of gas–liquid Taylor flows in a millimetric in-plane spiral shaped reactor with various tube curvature ratios (52 < λ < 166) is reported. Thanks to the compactness of the reactor and the use of an ad hoc imaging system and processing, the axial evolution of bubble lengths and velocities could be recorded and extracted along the whole reactor length (~3 m). The experimental results showed a significant linear increase of bubble length and velocity with axial position. Very long, stable Taylor bubbles (LB/dit up to 40) and liquid slugs were generated, in particular due to the poor wettability of the surface and the important role it played in bubble formation. At identical inertial force (i.e., identical Reynolds number), a higher centrifugal force (i.e., lower tube curvature ratio) likely led to shorter Taylor bubble lengths while only slightly affecting the liquid slug lengths. The axial pressure drop could be estimated from the axial increase in bubble volume, and compared with the measured pressure drop and that predicted by the correlations from literatures. By considering both the friction and capillary pressure drops, it was observed that the predicted two-phase pressure drop was slightly dependent on the centrifugal force and that the capillary pressure drop, determined from the unit cell number, capillary number and static contact angle, was dominant.

Similar content being viewed by others

REFERENCES

Paul, M., Strassl, F., Hoffmann, A., Hoffmann, M., Schlüter, M., and Herres-Pawlis, S., Reaction systems for bubbly flows, Eur. J. Inorg. Chem., 2018, vol. 2018, nos. 20–21, p. 2101.

Yue, J., Multiphase flow processing in microreactors combined with heterogeneous catalysis for efficient and sustainable chemical synthesis, Catal. Today, 2017, vol. 308, p. 3.

Radjagobalou, R., Blanco, J.-F., Dechy-Cabaret, O., Oelgemöller, M., and Loubière, K., Photooxygenation in an advanced led-driven flow reactor module: Experimental investigations and modelling, Chem. Eng. Process., 2018, vol. 130, p. 214.

Anxionnaz, Z., Cabassud, M., Gourdon, C., and Tochon, P., Heat exchanger/reactors (HEX reactors): Concepts, technologies: State-of-the-art, Chem. Eng. Process., 2008, vol. 47, no. 12, p. 2029.

Ganapathy, H., Al-Hajri, E., and Ohadi, M., Mass transfer characteristics of gas–liquid absorption during Taylor flow in mini/microchannel reactors, Chem. Eng. Sci., 2013, vol. 101, no. 14, p. 69.

Martínez, F.L.D., Julcour, C., Billet, A.-M., and Larachi, F., Modelling and simulations of a monolith reactor for three-phase hydrogenation reactions—Rules and recommendations for mass transfer analysis, Catal. Today, 2016, vol. 273, p. 121.

Kherbeche, A., Mei, M., Thoraval, M.-J., Hébrard, G., and Dietrich, N., Hydrodynamics and gas–liquid mass transfer around a confined sliding bubble, Chem. Eng. J. (in press).

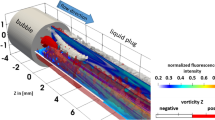

Yang, L., Loubière, K., Dietrich, N., Men, C.L., Gourdon, C., and Hébrard, G., Local investigations on the gas–liquid mass transfer around Taylor bubbles flowing in a meandering millimetric square channel, Chem. Eng. Sci., 2017, vol. 165, p. 192.

Kurt, S.K., Warnebold, F., Nigam, K.D.P., and Kockmann, N., gas–liquid reaction and mass transfer in microstructured coiled flow inverter, Chem. Eng. Sci., 2017, vol. 169, p. 164.

Aillet, T., Loubiere, K., Dechy-Cabaret, O., and Prat, L., Accurate measurement of the photon flux received inside two continuous flow microphotoreactors by actinometry, Int. J. Chem. React. Eng., 2014, vol. 12, no. 1, p. 257.

Hipolito, A., Rolland, M., Boyer, C., and De Bellefon, C., Single pellet string reactor for intensification of catalyst testing in gas/liquid/solid configuration, Oil Gas Sci. Technol.–Revue d’IFP Energies nouvelles, 2010, vol. 65, no. 5, p. 689.

Vashisth, S., Kumar, V., and Nigam, K.D., A review on the potential applications of curved geometries in process industry, Ind. Eng. Chem. Res., 2008, vol. 47, no. 10, p. 3291.

Aillet, T., Loubière, K., Dechy-Cabaret, O., and Prat, L., Microreactors as a tool for acquiring kinetic data on photochemical reactions, Chem. Eng. Technol., 2016, vol. 39, no. 1, p. 115.

Loubière, K., Oelgemöller, M., Aillet, T., Dechy-Cabaret, O., and Prat, L., Continuous-flow photochemistry: A need for chemical engineering, Chem. Eng. Process., 2016, vol. 104, p. 120.

Fellouah, H., Castelain, C., El Moctar, A.O., and Peerhossaini, H., A criterion for detection of the onset of Dean instability in Newtonian fluids, Eur. J. Mech., B, 2006, vol. 25, no. 4, p. 505.

Jimenez, M., Miller, B., and Bridle, H.L., Efficient separation of small microparticles at high flowrates using spiral channels: Application to waterborne pathogens, Chem. Eng. Sci., 2017, vol. 157, p. 247.

Fries, D.M. and von Rohr, P.R., Liquid mixing in gas–liquid two-phase flow by meandering microchannels, Chem. Eng. Sci., 2009, vol. 64, no. 6, p. 1326.

Abiev, R., Svetlov, S., and Haase, S., Hydrodynamics and mass transfer of gas–liquid and liquid-liquid Taylor flow in micro channels: A review, Chem. Eng. Technol., 2017, vol. 40, no. 11, p. 1985.

Haase, S., Murzin, D.Y., and Salmi, T., Review on hydrodynamics and mass transfer in minichannel wall reactors with gas–liquid Taylor flow, Chem. Eng. Res. Des., 2016, vol. 113, p. 304.

Abadie, T., Aubin, J., Legendre, D., and Xuereb, C., Hydrodynamics of gas–liquid Taylor flow in rectangular microchannels, Microfluid. Nanofluid., 2012, vol. 12, nos. 1–4, p. 355.

Abiev, R.S., Method for calculating the void fraction and relative length of bubbles under slug flow conditions in capillaries, Theor. Found. Chem. Eng., 2010, vol. 44, no. 1, p. 86.

Zaloha, P., Kristal, J., Jiricny, V., Völkel, N., Xuereb, C., and Aubin, J., Characteristics of liquid slugs in gas–liquid Taylor flow in microchannels, Chem. Eng. Sci., 2012, vol. 68, no. 1, p. 640.

Kumar, V., Vashisth, S., Hoarau, Y., and Nigam, K., Slug flow in curved microreactors: Hydrodynamic study, Chem. Eng. Sci., 2007, vol. 62, no. 24, p. 7494.

Muradoglu, M. and Stone, H.A., Motion of large bubbles in curved channels, J. Fluid Mech., 2007, vol. 570, p. 455.

Kawahara, A., Sadatomi, M., Matsuo, H., and Shimokawa, S., Investigation of characteristics of gas–liquid two-phase flows in a rectangular microchannel with return bends, Proc. ASME-JSME-KSME 2011 Joint Fluids Engineering Conference, 2011, p. 2461.

Ide, H., Kimura, R., Hashiguchi, H., and Kawaji, M., Effect of channel length on the gas–liquid two-phase flow phenomena in a microchannel, Heat Transfer Eng., 2012, vol. 33, no. 3, p. 225.

Molla, S., Eskin, D., and Mostowfi, F., Pressure drop of slug flow in microchannels with increasing void fraction: Experiment and modeling, Lab Chip, 2011, vol. 11, no. 11, p. 1968.

Lee, C.Y. and Lee, S.Y., Pressure drop of two-phase dry-plug flow in round mini-channels: Effect of moving contact line, Exp. Therm. Fluid Sci., 2010, vol. 34, no. 1, p. 1.

Choi, C., Yu, D.I., and Kim, M., Surface wettability effect on flow pattern and pressure drop in adiabatic two-phase flows in rectangular microchannels with T-junction mixer, Exp. Therm. Fluid Sci., 2011, vol. 35, no. 6, p. 1086.

Abiev, R.S., Effect of contact-angle hysteresis on the pressure drop under slug flow conditions in minichannels and microchannels, Theor. Found. Chem. Eng., 2015, vol. 49, no. 4, p. 414.

Qu, J., Wang, Q., Li, C., Han, X., and He, Z., A simple model for Taylor flow induced contact angle hysteresis and capillary pressure inside mini/micro-scale capillary tubes, Int. J. Heat Mass Transfer, 2014, vol. 78, p. 1004.

Ide, H., Kimura, R., Inoue, K., and Kawaji, M., Effect of wetting on adiabatic gas–liquid two-phase flow in a microchannel, Proc. ASME 6th International Conference on Nanochannels, Microchannels, and Minichannels, 2008, p. 337.

Abdelwahed, M.A.B., Wielhorski, Y., Bizet, L., and Bréard, J., Characterisation of bubbles formed in a cylindrical T-shaped junction device, Chem. Eng. Sci., 2012, vol. 76, p. 206.

Cubaud, T., Ulmanella, U., and How, C.-M., Two-phase flow in microchannels with surface modifications, Fluid Dyn. Res., 2006, vol. 38, no. 11, p. 772.

Roudet, M., Loubiere, K., Gourdon, C., and Cabassud, M., Hydrodynamic and mass transfer in inertial gas–liquid flow regimes through straight and meandering millimetric square channels, Chem. Eng. Sci., 2011, vol. 66, no. 13, p. 2974.

Krieger, W., Hörbelt, M., Schuster, S., Hennekes, J., and Kockmann, N., Kinetic study of leuco-indigo carmine oxidation and investigation of Taylor and Dean flow superposition in a coiled flow inverter, Chem. Eng. Technol., 2019, vol. 42, no. 10, p. 1.

Kováts, P., Pohl, D., Thévenin, D., and Zähringer, K., Optical determination of oxygen mass transfer in a helically-coiled pipe compared to a straight horizontal tube, Chem. Eng. Sci., 2018, vol. 190, p. 273.

Hosoda, S., Abe, S., Hosokawa, S., and Tomiyama, A., Mass transfer from a bubble in a vertical pipe, Int. J. Heat Mass Transfer, 2014, vol. 69, p. 215.

Dietrich, N., Loubière, K., Jimenez, M., Hébrard, G., and Gourdon, C., A new direct technique for visualizing and measuring gas–liquid mass transfer around bubbles moving in a straight millimetric square channel, Chem. Eng. Sci., 2013, vol. 100, p. 172.

Dietrich, N., Wongwailikhit, K., Mei, M., Xu, F., Felis, F., Kherbeche, A., Hébrard, G., and Loubière, K., Using the “red bottle” experiment for the visualization and the fast characterization of gas–liquid mass transfer, J. Chem. Educ., 2019, vol. 96, no. 5, p. 979.

Barajas, A. and Panton, R., The effects of contact angle on two-phase flow in capillary tubes, Int. J. Multiphase Flow, 1993, vol. 19, no. 2, p. 337.

Otsu, N., A threshold selection method from gray-level histograms, IEEE Trans. Syst., Man, Cybern., 1979, vol. 9, no. 1, p. 62.

Bretherton, F., The motion of long bubbles in tubes, J. Fluid Mech., 1961, vol. 10, no. 2, p. 166.

Van Steijn, V., Kreutzer, M.T., and Kleijn, C.R., μ-PIV study of the formation of segmented flow in microfluidic T-junctions, Chem. Eng. Sci., 2007, vol. 62, no. 24, p. 7505.

Garstecki, P., Fuerstman, M.J., Stone, H.A., and Whitesides, G.M., Formation of droplets and bubbles in a microfluidic T-junction—Scaling and mechanism of break-up, Lab Chip, 2006, vol. 6, no. 3, p. 437.

Laborie, S., Cabassud, C., Durand-Bourlier, L., and Laine, J., Characterisation of gas–liquid two-phase flow inside capillaries, Chem. Eng. Sci., 1999, vol. 54, no. 23, p. 5723.

Tsoligkas, A.N., Simmons, M.J.H., and Wood, J., Influence of orientation upon the hydrodynamics of gas–liquid flow for square channels in monolith supports, Chem. Eng. Sci., 2007, vol. 62, no. 16, p. 4365.

Kreutzer, M.T., Kapteijn, F., Moulijn, J.A., Kleijn, C.R., and Heiszwolf, J.J., Inertial and interfacial effects on pressure drop of Taylor flow in capillaries, AIChE J., 2005, vol. 51, no. 9, p. 2428.

Vashisth, S. and Nigam, K., Experimental investigation of pressure drop during two-phase flow in a coiled flow inverter, Ind. Eng. Chem. Res., 2007, vol. 46, no. 14, p. 5043.

ACKNOWLEDGMENTS

We thank Prof. Alain Line and Alexandre Boucher, who kindly provided valuable support and discussions for pressure drop and liquid film calculation.

Funding

The first author would like to acknowledge the financial assistance provided by the China Scholarship Council. We also acknowledge the support for this work from the CNRS research federation FERMaT (FR 3059).

Author information

Authors and Affiliations

Corresponding author

Additional information

Special issue: “Two-phase flows in microchannels: hydrodynamics, heat and mass transfer, chemical reactions”. Edited by R.Sh. Abiev

APPENDIX

APPENDIX

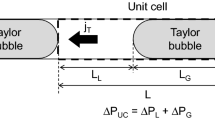

(1) Calculation of the bubble and liquid slug lengths

The bubble and liquid slug lengths are calculated based on the hypothesis that the nose and tail of the curved bubble and liquid slug are flat and that the liquid film thickness is negligible. Under these assumptions, as shown in Fig. A.1, the bubble area, AB, can be deduced from the difference between the outer sector OM1M2, Aouter, and the inner sector OM3M4, Ainner, such as

The bubble length, LB, is defined according to

By combining Eqs. (A.3) and (A.4), one obtains

Similarly, the liquid slug length can also be deduced from the liquid slug area, AS, and dit as

(2) Variation of the constant F2 related to the bubble velocity (Eq. (6))

Fig. A.1. The schematic diagram of the bubble length calculation.

Fig. A.2. Constant F2 versus gas–liquid flow ratio for configuration ET: (1) jL = 1.80 cm s–1; (2) jL = 3.61 cm s–1; (3) jL = 7.22 cm s–1; configuration MT: (4) jL = 1.80 cm s–1; (5) jL = 3.61 cm s–1; (6) jL = 7.22 cm s–1.

Rights and permissions

About this article

Cite this article

Mei Mei, Felis, F., Hébrard, G. et al. Hydrodynamics of Gas–Liquid Slug Flows in a Long In-Plane Spiral Shaped Milli-Reactor. Theor Found Chem Eng 54, 25–47 (2020). https://doi.org/10.1134/S0040579520010169

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0040579520010169