Abstract

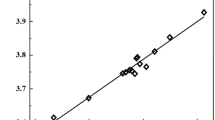

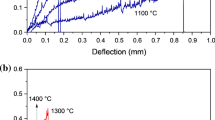

The mechanical properties of a porous diatomite-based ceramic have been studied. The results of a morphological analysis of the samples under study were used to examine the porous structure of the ceramic (morphology and average pore diameter) and determine the numerical value of the porosity of the samples (35–50%). The static (70–115 GPa) and dynamic (37–50 GPa) elasticity moduli of the samples were experimentally determined. The dependence of the dynamic modulus of the porous diatomite ceramic on porosity was examined: the elasticity moduli were found to decrease with increasing porosity of the material. The decrease in the porosity of the material after its being deformed was also found. It was observed that diatomite threads are formed after the samples were subjected to a compression deformation at a rate not exceeding 8 × 10–4 s–1.

Similar content being viewed by others

REFERENCES

L. Dong, C. Zhang, Y. Chen, L. Cao, J. Li, and L. Luo, Mater. Lett. 171, 108 (2016). https://doi.org/10.1016/j.matlet.2016.02.023

F. Akhtar, P. O. Vasiliev, and L. Bergström, J. Am. Ceram. Soc. 92, 338 (2009). https://doi.org/10.1111/j.1551-2916.2008.02882.x

D. G. Ri, S. Z. Qiu, and W. J. Bin, Adv. Mater. Res. 850–851, 1355 (2014). doi 10.4028/www.scientific.net/AMR.850-851

N. van Garderen, F. J. Clemens, M. Mezzomo, C. P. Bergmann, and T. Graule, Appl. Slay Sci. 52, 115 (2011). https://doi.org/10.1016/j.clay.2011.02.008

V. M. Fomin, S. G. Mironov, and K. M. Serdyuk, Tech. Phys. Lett. 35, 117 (2009). https://doi.org/10.1134/S1063785009020060

A. S. Konashuk, A. A. Sokolov, V. E. Drozd, A. A. Romanov, and E. O. Filatova, Tech. Phys. Lett. 38, 562 (2012). https://doi.org/10.1134/S1063785012060235

P. S. Vassileva, M. S. Apostolova, A. K. Detcheva, and E. H. Ivanova, Chem. Papers 67, 342 (2013). https://doi.org/10.2478/s11696-012-0272-x

L. Hao, W. Gao, S. Yan, M. Niu, G. Liu, and H. Hao, Mater. Chem. Phys. 235, 121741 (2019). https://doi.org/10.1016/j.matchemphys.2019.121741

H. Cheng, N. Cai, and M. Wang, Solid State Ionics 337, 12 (2019). https://doi.org/10.1016/j.ssi.2019.04.004

K. Li, X. Liu, T. Zheng, D. Jiang, Z. Zhou, C. Liu, X. Zhang, Y. Zhang, and D. Losic, Chem. Eng. J. 370, 136 (2019). https://doi.org/10.1016/j.cej.2019.03.190

M. V. Grigor’ev, N. L. Savchenko, S. P. Buyakova, and S. N. Kul’kov, Tech. Phys. Lett. 43, 723 (2017). https://doi.org/10.1134/S1063785017080089

A. A. Skvortsov, M. N. Luk’yanov, and Y. V. Novitsan, Solid State Phenom. 269, 71 (2017). doi 10.4028/www.scientific.net/SSP.269.71

G. Bruno, A. M. Efremov, A. N. Levandovskyi, and B. Clausen, J. Mater. Sci. 46, 161 (2011). https://doi.org/10.1007/s10853-010-4899-0

R. W. Rice, J. Mater. Sci. 40, 983 (2005). https://doi.org/10.1007/s10853-005-6517-0

Yu. E. Pivinskii and A. G. Romashin, Quartz Ceramics (Metallurgiya, Moscow, 1974) [in Russian].

S. P. Buyakova, V. I. Maslovskii, D. S. Nikitin, and S. N. Kul’kov, Tech. Phys. Lett. 27, 981 (2001). https://doi.org/10.1134/1.1432322

ACKNOWLEDGMENTS

The authors are grateful to S.G. Kalenkov for his interest in the study and stimulating discussions.

Funding

This study was carried out in the framework of project of the Ministry of Education and Science of the Russian Federation no. FZRR-2020-0023/code 0699-2020-0023.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflict of interest.

Additional information

Translated by M. Tagirdzhanov

Rights and permissions

About this article

Cite this article

Skvortsov, A.A., Luk’yanov, M.N., Chebeneva, I.E. et al. The Structure and Mechanical Properties of Porous Diatomite Ceramic upon Compression Deformation. Tech. Phys. Lett. 47, 166–169 (2021). https://doi.org/10.1134/S1063785021020292

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063785021020292