Abstract

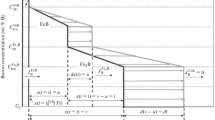

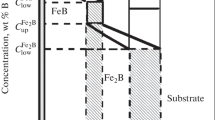

In this work, the Vanadis 6 steel was subjected to the solid boronizing treatment in the range of 950–1050°C, and for the durations between 0.75 and 10 h. The cross-sectional microstructures of boronized samples were investigated by scanning electron microscope, and the crystalline nature of phases present inside the boride layers was analysed by X-ray diffraction analysis. A kinetic approach basing on the integral diffusion model has been proposed for investigating the diffusion phenomena during the boronizing of examined steel. An adequate change of variables made in the derived system of differential algebraic equations (DAE) was employed to assess the values of boron diffusion coefficients in FeB and Fe2B. Boronizing within the temperature range 950–1050°C produced two-phase layers. These layers manifest less pronounced sawtooth morphology than what is typical for low-alloyed steels or for pure iron. The values of boron activation energies in FeB and Fe2B were 219.70 and 192.88 kJ mol–1.

Similar content being viewed by others

REFERENCES

Sinha, A.K., in ASM Handbook, vol. 4: Heat Treating, Materials Park, OH: ASM Int., 1999.

Kulka, M., in Current Trends in Boriding. Engineering Materials, Cham: Springer, 2019.

Carbucicchio, M. and Palombarini, G., J. Mater. Sci. Lett., 1987, vol. 6, p. 1147.

Hernández-Sánchez, E., Domínguez-Galicia, Y.M., Orozco-Álvarez, C., Carrera-Espinoza, R., Herrera-Hernández, H., and Velázquez, J.C., Adv. Mater. Sci. Eng., 2014, vol. 2014, p. 249174.

Campos-Silva, I., Ortiz-Domínguez, M., Cimenoglu, H., Escobar-Galindo, R., Keddam, M., ElíasEspinosa, M., and López-Perrusquia, N., Surf. Eng., 2011, vol. 27, no. 3, p. 189.

Mebarek, B., Keddam, M., and Aboshighiba, H., Rev. Sci. Technol. Inf., 2018, vol. 23, no. 5, p. 29.

Keddam, M. and Kulka, M., J. Min. Metall., Sect. B, 2018, vol. 54, no. 3, p. 361.

Brakman, C.M., Gommers, A.W.J., and Mittemeijer, E.J., J. Mater. Res., 1989, vol. 4, no. 6, p. 1354.

Yu, L., Chen, X., Khor, K., and Sundararajan, G., Acta Mater., 2005, vol. 53, p. 2361.

Campos, I., Torres, R., Bautista, O., Ramirez, G., and Zuniga, L., Appl. Surf. Sci., 2006, vol. 252, p. 2396.

Campos, I., Islas, M., González, E., Ponce, P., and Ramírez, G., Surf. Coat. Technol., 2006, vol. 201, p. 2717.

Campos, I., Islas, M., Ramírez, G., Villa Velázquez, C., and Mota, C., Appl. Surf. Sci., 2007, vol. 253, p. 6226.

Campos-Silva, I., Tadeo-Rosas, R., Santos-Medina, H.D., and Lopez-Garcıa, C., in Encyclopedia of Iron, Steel, and Their Alloys, Colas, R. and Totten, G.E., Eds., CRC Press, 2015.

Campos-Silva, I., Flores-Jiménez, M., Bravo-Bárcenas, D., Balmori-Ramírez, H., Andraca-Adame, J., Martínez-Trinidad, J., and Meda-Campaña, J.A., Surf. Coat. Technol., 2017, vol. 309, p. 155.

Nait Abdellah, Z. and Keddam, M., Mater. Technol., 2014, vol. 48, no. 2, p. 237.

Rayane, K. and Allaoui, O.‚ Defect Diffus. Forum, 2015, vol. 365, p. 194.

Türkmen, I., Yalamaç, E., and Keddam, M., Surf. Coat. Technol., 2019, vol. 377, p. 124888.

Keddam, M. and Kulka, M., Prot. Met. Phys. Chem. Surf., 2018, vol. 54, p. 282.

Keddam, M. and Kulka, M., Phys. Met. Metallogr., 2018, vol. 119, p. 842.

Zouzou, C. and Keddam, M., Ann. Chim. Sci. Mater., 2019, vol. 43, no. 3, p. 159.

Zouzou, C. and Keddam, M., Metall. Res. Technol., 2020, vol. 117, p. 202.

Keddam, M.‚ Acta Phys. Pol., A, 2018, vol. 133, no. 5, p. 1174.

Sen, S., Sen, U., and Bindal, C., Surf. Coat. Technol., 2005, vol. 191, p. 274.

Bartkowska, A., Bartkowski, D., Swadźba, R., Przestacki, D., and Miklaszewski, A., Int. J. Adv. Manuf. Technol., 2018, vol. 95, p. 1763.

Van Rompaey, T., Hari Kumar, K.C., and Wollants, P., J. Alloys Compd., 2002, vol. 334, p. 173.

Goodman, T.R., Adv. Heat Transfer, 1964, vol. 1, p. 51.

Kunst, H. and Schaaber, O., Haerterei-Tech. Mitt., 1967, vol. 22, p. 1.

Uslu, I., Omert, H., Ipek, M., Celebi, F.G., Ozdemir, O., and Bindal, C., Mater. Des., 2007, vol. 28, p. 1819.

Ünal, F. and Topuz, A., Mater. Test., 2016, vol. 58, no. 5, p. 418.

Kayali, Y., Akcin, Y., Mertgenc, E., and Gokce, B., Prot. Met. Phys. Chem. Surf., 2017, vol. 53, no. 1, p. 127.

Keddam, M., Chegroune, R., Kulka, M., Panfil, D., Ulker, S., and Taktak, S., Trans. Indian Inst. Met., 2017, vol. 70, p. 1377.

Kayali, Y. and Mertgenç, E., Prot. Met. Phys. Chem. Surf., 2020, vol. 56, no. 1, p. 151.

ACKNOWLEDGMENTS

The authors acknowledge that the paper is a result of the project implementation “Centre for Development and Application of Advanced Diagnostic Methods in Processing of Metallic and Non-Metallic Materials – APRODIMET”, ITMS: 26220120014, supported by the Research & Development Operational Programme funded by the ERDF.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Rights and permissions

About this article

Cite this article

Keddam, M., Hudáková, M., Ptačinová, J. et al. Modelling of the Boronizing Kinetics of Vanadis 6 Steel by the Integral Diffusion Model. Prot Met Phys Chem Surf 58, 347–355 (2022). https://doi.org/10.1134/S207020512202006X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S207020512202006X