Abstract

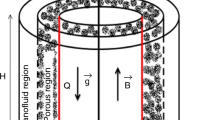

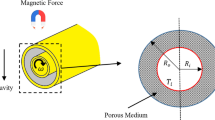

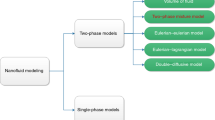

In this manuscript, phase change material (PCM) including the nanoparticles is considered in a 3D cubic enclosure to investigate the mixed convection of heat transfer under the magnetic field effect. Double rotating cylinders also are located in the middle of the enclosure to study the effect of their angular velocity in different conditions. Governing equations are solved by Galerkin Finite Element Method (GFEM) and were confirmed by previous studies. As main outcomes, results with enhanced angular velocity, both the average temperature and cumulative energy were significantly decreased. Furthermore, unaltered fluidity (\(\hbox {Ha}=0\)) imposes greater entropy, but this tendency reverses when the Hartman number (Ha) rises, resulting in minimum entropy trends.

Similar content being viewed by others

Data Availability

This manuscript has associated data in a data repository. [Authors’ comment: All data included in this manuscript are available upon request by contacting with the corresponding author.]

Abbreviations

- r:

-

Radius of the cylinder, [m]

- h:

-

Dimensional length of the heated wall (m)

- p:

-

Static pressure \((\hbox {N/m}^{2})\)

- Pr:

-

Prandtl number

- X,Y:

-

Dimensionless coordinate

- T:

-

Local temperature (\(^{^{\circ }}\hbox {K}\))

- u:

-

Velocity in the x-direction (m/s)

- v:

-

Velocity in the y-direction (m/s)

- U,V:

-

Dimensionless velocity

- \(C_{ps}\) :

-

solid PCM-specific heat (kJ/kgK)

- \(C_{pl}\) :

-

liquid PCM-specific heat (kJ/kgK)

- L:

-

latent heat of fusion of the PCM (kJ/kg)

- \(\hbox {T}_{\mathrm{m}}\) :

-

PCM melting temperature (K)

- \(\upalpha \) :

-

Thermal diffusivity (\(\hbox {m}^{2}/\hbox {s}\))

- \(\beta \) :

-

Coefficient of thermal expansion (\(1/^{{\circ }}\hbox {K}\))

- \(\theta \) :

-

Dimensionless temperature

- \(k_{ls}\) :

-

solid PCM thermal conductivity \((\hbox {W/m}\cdot \hbox {K})\)

- \(k_{l}\) :

-

liquid PCM thermal conductivity \((\hbox {W/m}\cdot \hbox {K})\)

- \(\rho _{l}\) :

-

liquid PCM density \(\left( \mathrm {kg/}\mathrm {m}^{\mathrm {3}} \right) \)

- \(\rho _{s}\) :

-

solid PCM density \(\left( \mathrm {kg/}\mathrm {m}^{\mathrm {3}} \right) \)

- \(\upnu \) :

-

Kinematic viscosity (\(\hbox {m}^{2\, }/\hbox {s}\))

- \(\upmu \) :

-

Dynamic viscosity (kg/ms)

- \(\Omega \) :

-

angular rotational speed of the cylinder, [rad/s]

References

F.S. Javadi, H.S.C. Metselaar, P. Ganesan, Performance improvement of solar thermal systems integrated with phase change materials (PCM), a review. Sol. Energy 206, 330–352 (2020)

N. Abdollahi, M. Rahimi, Heat transfer enhancement in a hybrid PV/PCM based cooling tower using Boehmite nanofluid, Heat Mass Transf. und Stoffuebertragung, pp. 859–869, 2019

A. E. Kabeel, M. M. Khairat Dawood, T. Nabil, B. E. Alonafal, Improving the performance of stepped solar still using a graphite and PCM as hybrid store materials with internal reflectors coupled with evacuated tube solar collector, Heat Mass Transf. und Stoffuebertragung, pp. 891–899, 2019

K. Du, J. Calautit, P. Eames, Y. Wu, A state-of-the-art review of the application of phase change materials (PCM) in Mobilized-Thermal Energy Storage (M-TES) for recovering low-temperature industrial waste heat (IWH) for distributed heat supply. Renew. Energy 168, 1040–1057 (2021)

L. Kalapala, J.K. Devanuri, Influence of operational and design parameters on the performance of a PCM based heat exchanger for thermal energy storage - A review. J. Energy Storage 20, 497–519 (2018)

D. Lee, C. Kang, Evaluation of heat storage and release in a double shell and tube heat exchanger with a PCM layer. J. Mech. Sci. Technol. 34(8), 3471–3480 (2020)

J. Park, D.H. Shin, Y. Shin, S.W. Karng, Analysis of heat transfer in latent heat thermal energy storage using a flexible PCM container. Heat Mass Transf. und Stoffuebertragung 55(6), 1571–1581 (2019)

M. S. Mahdi, H. B. Mahood, A. N. Campbell, A. A. Khadom, Natural convection improvement of PCM melting in partition latent heat energy storage: Numerical study with experimental validation, Int. Commun. Heat Mass Transf., vol. 126, 2021

D. Lee, C. Kang, A study on development of the thermal storage type plate heat exchanger including PCM layer. J. Mech. Sci. Technol. 33(12), 6085–6093 (2019)

W. Hua, L. Zhang, X. Zhang, Research on passive cooling of electronic chips based on PCM: A review. J. Mol. Liq. 340, 117183 (2021)

G. Murali, G. S. N. Sravya, J. Jaya, V. Naga Vamsi, A review on hybrid thermal management of battery packs and it’s cooling performance by enhanced PCM, Renew. Sustain. Energy Rev., 150: 111513, 2021

M. Joseph, V. Antony, and V. Sajith, Characterization of heat dissipation from PCM based heat sink using Mach–Zehnder Interferometry, Heat Mass Transf. und Stoffuebertragung, 2021

S. Rukh, R.A. Pasha, M.A. Nasir, Heat transfer enhancement of round pin heat sinks using N-eicosane as PCM: an experimental study. Heat Mass Transf. und Stoffuebertragung 55(2), 309–325 (2019)

M.H. Shojaeefard, G.R. Molaeimanesh, Y.S. Ranjbaran, Improving the performance of a passive battery thermal management system based on PCM using lateral fins. Heat Mass Transf. und Stoffuebertragung 55(6), 1753–1767 (2019)

J.F. Sánchez-Pérez, C. Mascaraque-Ramírez, J.A. Moreno Nicolás, E. Castro, M. Cánovas, Study of the application of PCM to thermal insulation of UUV hulls using Network Simulation Method. Alexandria Eng. J. 60(5), 4627–4637 (2021)

S. A. B. Al Omari, A. M. Ghazal, E. Elnajjar, A new approach using un-encapsulated discrete PCM chunks to augment the applicability of solid gallium as phase change material in thermal management applications, Energy Convers. Manag., vol. 158, no. December 2017, pp. 133–146, 2018

H. Usman, H.M. Ali, A. Arshad, M.J. Ashraf, S. Khushnood, M.M. Janjua, S.N. Kazi, An experimental study of PCM based finned and un-finned heat sinks for passive cooling of electronics. Heat Mass Transf. und Stoffuebertragung 54(12), 3587–3598 (2018)

A. Kasaeian, L. Bahrami, F. Pourfayaz, E. Khodabandeh, W.-M. Yan, Experimental studies on the applications of PCMs and nano-PCMs in buildings: A critical review. Energy Build. 154, 96–112 (2017)

D. Zhou, C.Y. Zhao, Y. Tian, Review on thermal energy storage with phase change materials (PCMs) in building applications. Appl. Energy 92, 593–605 (2012)

T. Yan, J. Li, J. Gao, X. Xu, J. Yu, Model validation and application of the coupled system of pipe-encapsulated PCM wall and nocturnal sky radiator. Appl. Therm. Eng. 194(December), 2021 (2020)

V. Vinayaka Ram, R. Singhal, R. Parameshwaran, Energy efficient pumpable cement concrete with nanomaterials embedded PCM for passive cooling application in buildings. Mater. Today Proc. 28, 1054–1063 (2019)

J.H. Park, J. Jeon, J. Lee, S. Wi, B.Y. Yun, S. Kim, Comparative analysis of the PCM application according to the building type as retrofit system. Build. Environ. 151(January), 291–302 (2019)

G. Evola, L. Marletta, F. Sicurella, Simulation of a ventilated cavity to enhance the effectiveness of PCM wallboards for summer thermal comfort in buildings. Energy Build. 70, 480–489 (2014)

Z. Xiao, P. Mishra, A. Mahdavi Nejad, M. Tao, S. Granados-Focil, S. Van Dessel, Thermal optimization of a novel thermo-optically responsive SS-PCM coatings for building enclosures, Energy Build., vol. 247, 2021.

H.-D. Yun, K.-L. Ahn, S.-J. Jang, B.-S. Khil, W.-S. Park, S.-W. Kim, Thermal and Mechanical Behaviors of Concrete with Incorporation of Strontium-Based Phase Change Material (PCM). Int. J. Concr. Struct. Mater. 13(1), 18 (2019)

Y. Lin, Y. Jia, G. Alva, G. Fang, Review on thermal conductivity enhancement, thermal properties and applications of phase change materials in thermal energy storage. Renew. Sustain. Energy Rev. 82, 2730–2742 (2018)

Z.A. Qureshi, H.M. Ali, S. Khushnood, Recent advances on thermal conductivity enhancement of phase change materials for energy storage system: A review. Int. J. Heat Mass Transf. 127, 838–856 (2018)

S. Wu, T. Yan, Z. Kuai, W. Pan, Thermal conductivity enhancement on phase change materials for thermal energy storage: A review. Energy Storage Mater. 25, 251–295 (2020)

N. Sharifi, T.L. Bergman, A. Faghri, Enhancement of PCM melting in enclosures with horizontally-finned internal surfaces. Int. J. Heat Mass Transf. 54(19–20), 4182–4192 (2011)

C. Zhao, M. Opolot, M. Liu, F. Bruno, S. Mancin, K. Hooman, Numerical study of melting performance enhancement for PCM in an annular enclosure with internal-external fins and metal foams. Int. J. Heat Mass Transf. 150, 119348 (2020)

C. Ji, Z. Qin, S. Dubey, F.H. Choo, F. Duan, Simulation on PCM melting enhancement with double-fin length arrangements in a rectangular enclosure induced by natural convection. Int. J. Heat Mass Transf. 127, 255–265 (2018)

X. Zhou, Q. Yu, S. Zhang, C. Zhang, J. Feng, Porous silica matrices infiltrated with PCM for thermal protection purposes. Ceram. Int. 39(5), 5247–5253 (2013)

Y. Li, J. Li, Y. Deng, W. Guan, X. Wang, T. Qian, Preparation of paraffin/porous TiO2 foams with enhanced thermal conductivity as PCM, by covering the TiO2 surface with a carbon layer. Appl. Energy 171, 37–45 (2016)

W. Peng, O.K. Sadaghiani, Thermal function improvement of phase-change material (PCM) using alumina nanoparticles in a circular-rectangular cavity using Lattice Boltzmann method. J. Energy Storage 37(March), 102493 (2021)

M. Bashar, K. Siddiqui, Experimental investigation of transient melting and heat transfer behavior of nanoparticle-enriched PCM in a rectangular enclosure. J. Energy Storage 18(June), 485–497 (2018)

M.M. Rashidi, M. Sadri, M.A. Sheremet, Numerical Simulation of Hybrid Nanofluid Mixed Convection in a Lid-Driven Square Cavity with Magnetic Field Using High-Order Compact Scheme. Nanomaterials 11(9), 2250 (2021)

M.M. Rashidi, F. Mohammadi, S. Abbasbandy, M.S. Alhuthali, Entropy Generation Analysis for Stagnation Point Flow in a Porous Medium over a Permeable Stretching Surface. J. Appl. Fluid Mech. 8(4), 753–765 (2015)

M.V. Reddya, P. Lakshminarayana, Cross-diffusion and heat source effects on a three-dimensional MHD flow of Maxwell nanofluid over a stretching surface with chemical reaction. Eur. Phys. J. Spec. Top. 230, 1371–1379 (2021)

M.V. Reddy, P. Lakshminarayana, influence of thermal radiation and viscous dissipation on MHD flow of UCM fluid over a porous stretching sheet with higher order chemical reaction. Spec. Top. Rev. Porous Media Int. J. 12(4), 33–49 (2021)

M.V. Reddy, P. Lakshminarayana, K. Vajravelu, Magnetohydrodynamic radiative flow of a Maxwell fluid on an expanding surface with the effects of Dufour and Soret and chemical reaction. Comput. Therm. Sci. 12(4), 317–327 (2020)

R. Meenakumari, P. Lakshminarayana, Radiation and Hall effects on a 3D flow of MHD Williamson fluid over a stretchable surface. Heat Transfer. 49, 4410–4426 (2020)

M.V. Reddy, P. Lakshminarayana, K. Vajravelu, A comparative study of MHD non-Newtonian fluid flows with the effects of chemical reaction and radiation over a stretching sheet. Comput. Therm. Sci. 13(5), 17–29 (2021)

G. Sucharitha, M.M. Rashidi, S. Sreenadh, P. Lakshminarayana, Effects of magnetic field and slip on convective peristaltic flow of a non-Newtonian fluid in an inclined non-uniform porous channel with flexible walls. J. Porous Media 21(10), 895–910 (2018)

R. Meenakumari, P. Lakshminarayana, K. Vajravelu, Unsteady MHD flow of a Williamson nanofluid on a permeable stretching surface with radiation and chemical reaction effects. Euro. Phys. J. Spec. Top. 230, 1355–1370 (2021)

M.M. Rashidi, S. Bagheri, E. Momoniat, N. Freidoonimehr, Entropy analysis of convective MHD flow of third grade non-Newtonian fluid over a stretching sheet. Ain Shams Eng. J. 8(1), 77–85 (2017)

O. Fatla, G. Smaisim, A. Valera-Medina1, A. Rageb, N. Syred, Experimental and Numerical Investigation of Heat Transfer and Fluid Mechanics across a Rotating Circular Cylinder Dissipating Uniform Heat Flux by Crossflow. 10th Pacific Symposium on Flow Visualization and Image Processing Naples, Italy, 15-18 June, 2015

Wael Al-Kouz, Abderrahmane Aissa, Aimad Koulali, Wasim Jamshed, Hazim Moria, Kottakkaran Sooppy Nisar, Abed Mourad, Abdel-Haleem Abdel-Aty, M. Motawi Khashan & I. S. Yahia, MHD darcy-forchheimer nanofluid flow and entropy optimization in an odd-shaped enclosure filled with a (MWCNT-Fe3O4/water) using galerkin finite element analysis. Sci Rep 11, 22635 (2021)

Weal Al-Kouz, Aissa Abderrahmane, MD. Shamshuddin, Obai Younis, Sahnoun Mohammed, O. Anwar Beg and Davood Toghraie. Heat transfer and entropy generation analysis of water-Fe3O4/CNT hybrid magnetic nanofluid flow in a trapezoidal wavy enclosure containing porous media with the Galerkin finite element method. Eur. Phys. J. Plus 136, 1184 (2021)

W. Al-Kouz, M.A. Medebber, Mohamed Abdelghany Elkotb, Aissa Abderrahmane, Koulali Aimad, Khaled Al-Farhany, Wasim Jamshed, Hazim Moria, Fayez Aldawi, C. Ahamed Saleel, Kottakkaran Sooppy Nisar, Galerkin finite element analysis of Darcy-Brinkman-Forchheimer natural convective flow in conical annular enclosure with discrete heat sources, Energy Reports 7, 6172–6181 (2021)

A.J. Chamkha, F. Selimefendigil, MHD mixed convection of nanofluid due to an inner rotating cylinder in a 3D enclosure with a phase change material. Int. J. Numer. Methods Heat Fluid Flow 29(10), 3559–3583 (2019)

K. Kant, A. Shukla, A. Sharma, P.H. Biwole, Heat transfer studies of photovoltaic panelcoupled with phase change material. Sol. Energy 140, 151–161 (2016)

V. Alexiades, N. Hannoun, and T.Z. Mai, Tin Melting: Effect of Grid Size and Scheme on the Numerical Solution, In Proc. 5th Mississippi State Conf. Differential Equations and Computational Simulations, pp. 55–69, 2003

A. Verma, S. Shashidhara, D. Rakshit, A comparative study on battery thermal management using phase change material (PCM). Therm. Sci. Eng. Prog. 11, 74–83 (2019)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abderrahmane, A., Hatami, M., Younis, O. et al. Effect of double rotating cylinders on the MHD mixed convection and entropy generation of a 3D cubic enclosure filled by nano-PCM. Eur. Phys. J. Spec. Top. 231, 2569–2581 (2022). https://doi.org/10.1140/epjs/s11734-022-00586-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1140/epjs/s11734-022-00586-7