Abstract

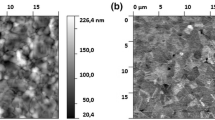

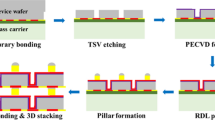

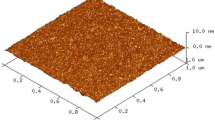

Wafer bonding is an emerging technology for fabrication of complex three-dimensional (3D) structures; particularly it enables monolithic wafer-level 3D integration of high performance, multi-function microelectronic systems. For such a 3D integrated circuits, low-temperature wafer bonding is required to be compatible with the back-end-of-the-line processing conditions. Recently our investigation on surface melting characteristics of copper nanorod arrays showed that the threshold of the morphological changes of the nano-rod arrays occurs at a temperature significantly below the copper bulk melting point. With this unique property of the copper nanorod arrays, wafer bonding using copper nanorod arrays as a bonding intermediate layer was investigated at low temperatures (400 °C and lower). 200 mm Wafers, each with a copper nanorod array layer, were bonded at 200 – 400 °C and with a bonding down-force of 10 kN in a vacuum chamber. Bonding results were evaluated by razor blade test, mechanical grinding and polishing, and cross-section imaging using a focus ion beam/scanning electron microscope (FIB/SEM). The FIB/SEM images show that the copper nanorod arrays fused together accompanying by a grain growth at a bonding temperature of as low as 200 °C. A dense copper bonding layer was achieved at 400 °C where copper grains grew throughout the copper structure and the original bonding interface was eliminated. The sintering of such nanostructures depends not only on their feature size, but also significantly influenced by the bonding pressure. These two factors both contribute to the mass transport in the nanostructure, leading to the formation of a dense bonding layer.

Similar content being viewed by others

References

J. Voldman, M. L. Gary, and M. A. Schmidt, Annu. Rev. Biomed. Eng., 1, 401 (1999).

F. Niklaus, J.-Q. Lu, G. Stemme, and R. Gutmann, J. of Appl. Phys. (Applied Physics Review – Focused Review), 99 (3), 031101 (2006).

A. J. Pitera, G. Taraschi, M. L. Lee, C. W. Leitz, Z.-Y. Cheng, and E. A. Fitzgerald, Journal of The Electrochemical Society, 151 (7), G443 (2004).

A. Murai, D. B. Thompson, H. Masui, N. Fellows, U. K. Mishra, S. Nakamura, and S. P. DenBaars, Appl. Phys. Lett., 89, 171116 (2006).

J.-Q. Lu, T.S. Cale and R.J. Gutmann, in Dielectrics for Nanosystems: Materials, Science, Processing, Reliability, and Manufacturing, ECS PV 2004–04, pp. 312–323 (2004).

K. N. Chen, C. S. Tan, A. Fan, and R. Reif, Electrochemical and Solid-State Letters, 7 (1), G14 (2004).

K.-N. Chen, S.H. Lee, P.S. Andry, C.K. Tsang, A.W. Topol, Y.-M. Lin, J.-Q. Lu, A.M.Young, M. Ieong, and W. Haensch, 2006 IEEE International Electron Devices Meeting (IEDM 2006), in press.

T. Karabacak, J. S. Deluca, P.-I. Wang, G. A. Ten Eyck, D. Ye, G.-C Wang,a nf T.-M. Lu. Journal of Applied Physics, 99, 064304 (2006).

R. M. German, Power Metallurgy Science, Metal Powder Industries Federation, NJ, (1989).

J. Liu, A. L. Cardamone, and R. M. German, Power Metallurgy, 44 (4), 317 (2001).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Wang, PI., Karabacak, T., Yu, J. et al. Low Temperature Copper-Nanorod Bonding for 3D Integration. MRS Online Proceedings Library 970, 407 (2006). https://doi.org/10.1557/PROC-0970-Y04-07

Received:

Accepted:

Published:

DOI: https://doi.org/10.1557/PROC-0970-Y04-07