Abstract

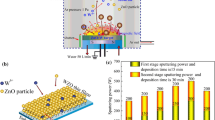

The use of zinc nitride (Zn3N2) films as a transparent electrode in various electronic devices has attracted much attention owing to its high-carrier mobility. In this study, we investigate the influence of the sputtering process on structural, optical, and electrical properties of a Zn3N2 film deposited by reactive magnetron sputtering. The reactivity of nitrogen species can be improved by changing the type of sputtering gas. Compared with Ar or Ne sputtering gas, polycrystalline Zn3N2 films deposited using He sputtering gas have a larger grain size. The optical band gap of the Zn3N2 films varied from ~1.2 to 1.5 eV depending on the N2 flow ratio and type of sputtering gas. The maximum mobility was 91.1 cm2/Vs when the Zn3N2 film was deposited using Ar sputtering gas with an N2 flow ratio of 40%. The carrier density of Zn3N2 films deposited using Ar sputtering gas was notably higher than those deposited using Ne or He sputtering gas, and more oxygen atoms are considered to substitute into nitrogen sites, where oxygen is considered to be from the residual water vapor in the sputtering chamber.

Similar content being viewed by others

References

K. Toyoura, H. Tsujimura, T. Goto, K. Hachiya, R. Hagiwara, and Y. Ito: Optical properties of zinc nitride formed by molten salt electrochemical process. Thin Solid Films 492, 88–92 (2005).

R. Long, Y. Dai, L. Yu, M. Guo, and B. Huang: Structural, electronic, and optical properties of oxygen defects in Zn3N2. J. Phys. Chem. B 111, 3379–3383 (2007).

T. Oshima, and S. Fujita: (111)-oriented Zn3N2 growth on a-plane sapphire substrates by molecular beam epitaxy. Jpn. J. Appl. Phys. 45, 8653–8655 (2006).

D.E. Partin, D.J. Williams, and M. O’Keefee: The Crystal Structures of Mg3N2 and Zn3N2. J. Solid State Chem. 132, 56–59 (1997).

M. Futsuhara, K. Yoshioka, and O. Takai: Structural, electrical and optical properties of zinc nitride thin films prepared by reactive rf magnetron sputtering. Thin Solid Films 322, 274–281 (1998).

P. Wu, T. Tiedje, H. Alimohammadi, V. Bahrami-Yekta, M. Masnadi-Shirazi, and C. Wang: Molecular beam epitaxy growth and optical properties of single crystal Zn3N2 films. Semicond. Sci. Technol. 31, 10LT01 (2016).

X. Cao, Y. Yamaguchi, Y. Ninomiya, and N. Yamada: Comparative study of electron transport mechanisms in epitaxial and polycrystalline zinc nitride films. J. Appl. Phys. 119, 025104 (2016).

X. Cao, A. Sato, Y. Ninomiya, and N. Yamada: Oxygen-doped zinc nitride as a high-mobility nitride-based semiconductor. J. Phys. Chem. C 119, 5327–5333 (2007).

K. Kuriyama, Y. Takahashi, and F. Sunohara: Optical band gap of Zn3N2 films. Phys. Rev. B 48, 2781–2782 (1993).

R. Ayouchi, C. Casteleiro, L. Santos, and R. Schwarz: RF-plasma assisted PLD growth of Zn3N2 thin films. Phys. Status Solidi C 7, 2294–2297 (2010).

W. Du, F. Zong, H. Ma, J. Ma, M. Zhang, X. Feng, H. Li, Z. Zhang, and P. Zhao: Optical band gap of zinc nitride films prepared by reactive rf magnetron sputtering. Cryst. Res. Technol. 41, 889–892 (2006).

R. Long, Y. Dai, L. Yu, B. Huang, and S. Han: Atomic geometry and electronic structure of defects in Zn3N2. Thin Solid Films 516, 1297 (2008).

Y. Kumagai, K. Harada, H. Akamatsu, K. Matsuzaki, and F. Oba: Carrier-induced band-gap variation and point defects in Zn3N2 from first principles. Phys. Rev. Appl. 8, 014015 (2017).

E. Burstein: Anomalous optical absorption limit in InSb. Phys. Rev. 93, 632 (1954).

T.S. Moss: The interpretation of the properties of indium antimonide. Proc. Phys. Soc. Lond. Sect. B 67, 775 (1954).

Powder Diffraction File Compiled by the Joint Committee on Powder Diffraction, Card No. 35-0762 (1985).

B. Chapman: Glow Discharge Processes: Sputtering and Plasma Etching (Wiley-Interscience, USA, 1980), pp. 181–280.

F. Zong, H. Ma, C. Xue, H. Zhuang, X. Zhang, H. Xiao, J. Ma, and F. Ji: Synthesis and thermal stability of Zn3N2 powder. Solid State Commun. 132, 521–525 (2004).

M. Kusayanagi, A. Uchida, N. Oka, J. Jia, S. Nakamura, and Y. Shigesato: Al-doped ZnO films deposited on a slightly reduced buffer layer by reactive dc unbalanced magnetron sputtering. Thin Solid Films 555, 93–99 (2014).

J. Jia, N. Oka, M. Kusayanagi, S. Nakatom, and Y. Shigesato: Origin of carrier scattering in polycrystalline Al-doped ZnO films. Appl. Phys. Express 7, 105802 (2014).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jia, J., Kamijo, H., Nakamura, Si. et al. How the sputtering process influence structural, optical, and electrical properties of Zn3N2 films?. MRS Communications 8, 314–321 (2018). https://doi.org/10.1557/mrc.2018.50

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/mrc.2018.50