Abstract

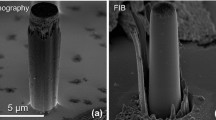

In situ TEM nanopillar compression experiments are widely used to study the mechanical behavior of nanoscale materials. Often, the pillars are fabricated using gallium-focused ion beam (FIB) milling from a bulk sample. During the FIB process, the choice of the pillar shape and the energy of the Ga ions can significantly impact the mechanical performance of samples with electron-transparent dimensions. Here, we systematically explore the effects of various pillar fabrication parameters in a single crystal aluminum (Al) system with a well-controlled crystal orientation. A novel method is proposed to fabricate square pillars to minimize FIB artifacts such as tapering, high pillar base compliance, and preferential deformation at the pillar tip. These square pillars enable more uniform deformation and accurate measurement of the engineering strain. Lastly, we show an intriguing in situ TEM laser irradiation experiment, which has enabled direct visualization of the surface oxide layer in FIB-fabricated Al pillars.

Graphic Abstract

Similar content being viewed by others

Data and materials availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

O.V. Kuzmin, Y.T. Pei, C.Q. Chen, J.T.M. De Hosson, Intrinsic and extrinsic size effects in the deformation of metallic glass nanopillars. Acta Mater. 60(3), 889 (2012)

M. Chen, L. Pethö, A.S. Sologubenko, H. Ma, J. Michler, R. Spolenak, J.M. Wheeler, Achieving micron-scale plasticity and theoretical strength in Silicon. Nat. Commun. 11(1), 2681 (2020)

M.C. Liu, J.C. Huang, K.W. Chen, J.F. Lin, W.D. Li, Y.F. Gao, T.G. Nieh, Is the compression of tapered micro- and nanopillar samples a legitimate technique for the identification of deformation mode change in metallic glasses? Scr. Mater. 66(10), 817 (2012)

Y.H. Lai, C.J. Lee, Y.T. Cheng, H.S. Chou, H.M. Chen, X.H. Du, C.I. Chang, J.C. Huang, S.R. Jian, J.S.C. Jang, T.G. Nieh, Bulk and microscale compressive behavior of a Zr-based metallic glass. Scr. Mater. 58(10), 890 (2008)

H. Zhang, J. Tersoff, S. Xu, H. Chen, Q. Zhang, K. Zhang, Y. Yang, C.-S. Lee, K.-N. Tu, J. Li, Y. Lu, Approaching the ideal elastic strain limit in silicon nanowires. Sci. Adv. 2(8), e1501382 (2016)

P. Hosemann, C. Shin, D. Kiener, Small scale mechanical testing of irradiated materials. J. Mater. Res. 30(9), 1231 (2015)

D. Kiener, A.M. Minor, O. Anderoglu, Y. Wang, S.A. Maloy, P. Hosemann, Application of small-scale testing for investigation of ion-beam-irradiated materials. J. Mater. Res. 27(21), 2724 (2012)

P. Hosemann, Small-scale mechanical testing on nuclear materials: bridging the experimental length-scale gap. Scr. Mater. 143, 161 (2018)

K.H. Yano, M.J. Swenson, Y. Wu, J.P. Wharry, TEM in situ micropillar compression tests of ion irradiated oxide dispersion strengthened alloy. J. Nucl. Mater. 483, 107 (2017)

D. Kiener, P. Hosemann, S.A. Maloy, A.M. Minor, In situ nanocompression testing of irradiated copper. Nat. Mater. 10(8), 608 (2011)

M.D. Uchic, Sample dimensions influence strength and crystal plasticity. Science 305(5686), 986 (2004)

J. Hütsch, E.T. Lilleodden, The influence of focused-ion beam preparation technique on microcompression investigations: Lathe vs. annular milling. Scr. Mater. 77, 49 (2014)

Z.W. Shan, R.K. Mishra, S.A. Syed Asif, O.L. Warren, A.M. Minor, Mechanical annealing and source-limited deformation in submicrometre-diameter Ni crystals. Nat. Mater. 7(2), 115 (2008)

M.D. Uchic, D.M. Dimiduk, A methodology to investigate size scale effects in crystalline plasticity using uniaxial compression testing. Mater. Sci. Eng., A 400–401(1–2 SUPPL.), 268 (2005)

D.-G. Xie, R.-R. Zhang, Z.-Y. Nie, J. Li, E. Ma, J. Li, Z.-W. Shan, Deformation mechanism maps for sub-micron sized aluminum. Acta Mater. 188, 570 (2020)

Z.-J. Wang, Q.-J. Li, Z.-W. Shan, J. Li, J. Sun, E. Ma, Sample size effects on the large strain bursts in submicron aluminum pillars. Appl. Phys. Lett. 100(7), 071906 (2012)

C.Q. Chen, Y.T. Pei, O. Kuzmin, Z.F. Zhang, E. Ma, J.T.M. De Hosson, Intrinsic size effects in the mechanical response of taper-free nanopillars of metallic glass. Phys. Rev. B 83(18), 180201 (2011)

T.A. Parthasarathy, S.I. Rao, D.M. Dimiduk, M.D. Uchic, D.R. Trinkle, Contribution to size effect of yield strength from the stochastics of dislocation source lengths in finite samples. Scr. Mater. 56(4), 313 (2007)

S.I. Rao, D.M. Dimiduk, T.A. Parthasarathy, M.D. Uchic, M. Tang, C. Woodward, Athermal mechanisms of size-dependent crystal flow gleaned from three-dimensional discrete dislocation simulations. Acta Mater. 56(13), 3245 (2008)

A.M. Minor, S.A. Syed Asif, Z. Shan, E.A. Stach, E. Cyrankowski, T.J. Wyrobek, O.L. Warren, A new view of the onset of plasticity during the nanoindentation of aluminium. Nat. Mater. 5(9), 697 (2006)

J. Ye, R.K. Mishra, A.M. Minor, Relating nanoscale plasticity to bulk ductility in aluminum alloys. Scr. Mater. 59(9), 951 (2008)

J. Jeong, S. Lee, Y. Kim, S.M. Han, D. Kiener, Y.-B. Kang, S.H. Oh, Microstructural evolution of a focused ion beam fabricated Mg nanopillar at high temperatures: defect annihilation and sublimation. Scr. Mater. 86, 44 (2014)

H. Bei, S. Shim, E.P. George, M.K. Miller, E.G. Herbert, G.M. Pharr, Compressive strengths of molybdenum alloy micro-pillars prepared using a new technique. Scr. Mater. 57(5), 397 (2007)

B.-Y. Liu, F. Liu, N. Yang, X.-B. Zhai, L. Zhang, Y. Yang, B. Li, J. Li, E. Ma, J.-F. Nie, Z.-W. Shan, Large plasticity in magnesium mediated by pyramidal dislocations. Science 365(6448), 73 LP (2019)

M.C. Liu, J.C. Huang, H.S. Chou, Y.H. Lai, C.J. Lee, T.G. Nieh, A nanoscaled underlayer confinement approach for achieving extraordinarily plastic amorphous thin film. Scr. Mater. 61(8), 840 (2009)

J. Mayer, L.A. Giannuzzi, T. Kamino, J. Michael, TEM sample preparation and FIB-induced damage. MRS Bull. 32(5), 400 (2007)

P.J. Imrich, C. Kirchlechner, D. Kiener, G. Dehm, In situ TEM microcompression of single and bicrystalline samples: insights and limitations. JOM 67(8), 1704 (2015)

C.A. Volkert, A.M. Minor, Focused ion beam microscopy and micromachining. MRS Bull. 32(5), 389 (2007)

C.Q. Chen, Y.T. Pei, J.T.M. De Hosson, Apparently homogeneous but intrinsically intermittent flow of taper-free metallic glass nanopillars. Scr. Mater. 67(12), 947 (2012)

F. Hofmann, E. Tarleton, R.J. Harder, N.W. Phillips, P.-W. Ma, J.N. Clark, I.K. Robinson, B. Abbey, W. Liu, C.E. Beck, 3D lattice distortions and defect structures in ion-implanted nano-crystals. Sci. Rep. 7(1), 45993 (2017)

C. Lehrer, L. Frey, S. Petersen, M. Mizutani, M. Takai, and H. Ryssel: in 2000 International Conference on Ion Implantation Technology Proceedings. Ion Implantation Technology—2000 (Cat. No.00EX432) (2000), pp. 695–698

S. Lee, J. Jeong, Y. Kim, S.M. Han, D. Kiener, S.H. Oh, FIB-induced dislocations in Al submicron pillars: annihilation by thermal annealing and effects on deformation behavior. Acta Mater. 110, 283 (2016)

S. Shim, H. Bei, M.K. Miller, G.M. Pharr, E.P. George, Effects of focused ion beam milling on the compressive behavior of directionally solidified micropillars and the nanoindentation response of an electropolished surface. Acta Mater. 57(2), 503 (2009)

H.H. Shen, X.T. Zu, B. Chen, C.Q. Huang, K. Sun, Direct observation of hydrogenation and dehydrogenation of a zirconium alloy. J. Alloys Compd. 659, 23 (2016)

W.F. van Dorp, C.W. Hagen, A critical literature review of focused electron beam induced deposition. J. Appl. Phys. 104(8), 081301 (2008)

L. Jiang, N. Chawla, Mechanical properties of Cu6Sn5 intermetallic by micropillar compression testing. Scr. Mater. 63(5), 480 (2010)

O. Kuzmin, Y. Pei, J.T.M. De Hosson, In situ compression study of taper-free metallic glass nanopillars. Appl. Phys. Lett. 98, 233104 (2011)

M. Chen, J. Wehrs, J. Michler, J.M. Wheeler, High-temperature in situ deformation of GaAs micro-pillars: lithography versus FIB machining. JOM 68(11), 2761 (2016)

M.J. Burek, J.R. Greer, Fabrication and microstructure control of nanoscale mechanical testing specimens via electron beam lithography and electroplating. Nano Lett. 10(1), 69 (2010)

K.A. Unocic, M.J. Mills, G.S. Daehn, Effect of gallium focused ion beam milling on preparation of aluminium thin foils. J. Microsc. 240(3), 227 (2010)

D.J. Magagnosc, G. Kumar, J. Schroers, P. Felfer, J.M. Cairney, D.S. Gianola, Effect of ion irradiation on tensile ductility, strength and fictive temperature in metallic glass nanowires. Acta Mater. 74, 165 (2014)

F. Hofmann, R.J. Harder, W. Liu, Y. Liu, I.K. Robinson, Y. Zayachuk, Glancing-incidence focussed ion beam milling: a coherent X-ray diffraction study of 3D nano-scale lattice strains and crystal defects. Acta Mater. 154, 113 (2018)

T. Vermeij, E. Plancher, C.C. Tasan, Preventing damage and redeposition during focused ion beam milling: the “umbrella” method. Ultramicroscopy 186, 35 (2018)

T. Pekin, F. Allen, A. Minor, Evaluation of neon focused ion beam milling for TEM sample preparation. J. Microsc. 264, 59–63 (2016)

Y.-C. Wang, L. Tian, F. Liu, Y.-B. Qin, G. Zheng, J.-T. Wang, E. Ma, Z.-W. Shan, Helium ion microscope fabrication causing changes in the structure and mechanical behavior of silicon micropillars. Small 13(1), 1601753 (2017)

J. Liu, R. Niu, J. Gu, M. Cabral, M. Song, X. Liao, Effect of ion irradiation introduced by focused ion-beam milling on the mechanical behaviour of sub-micron-sized samples. Sci. Rep. 10(1), 10324 (2020)

M.-S. Ding, J.-P. Du, L. Wan, S. Ogata, L. Tian, E. Ma, W.-Z. Han, J. Li, Z.-W. Shan, Radiation-induced helium nanobubbles enhance ductility in submicron-sized single-crystalline copper. Nano Lett. 16(7), 4118 (2016)

Y. Yang, A. Kushima, W. Han, H. Xin, J. Li, Liquid-like, self-healing aluminum oxide during deformation at room temperature. Nano Lett. 18(4), 2492 (2018)

F.G. Sen, A.T. Alpas, A.C.T. van Duin, Y. Qi, Oxidation-assisted ductility of aluminium nanowires. Nat. Commun. 5(1), 3959 (2014)

S. Brochard, P. Hirel, L. Pizzagalli, J. Godet, Elastic limit for surface step dislocation nucleation in face-centered cubic metals: temperature and step height dependence. Acta Mater. 58(12), 4182 (2010)

J.F. Ziegler, M.D. Ziegler, J.P. Biersack, SRIM - The stopping and range of ions in matter. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms. 268(11–12), 1818 (2010)

Y.G. Li, Y. Yang, M.P. Short, Z.J. Ding, Z. Zeng, J. Li, IM3D: a parallel Monte Carlo code for efficient simulations of primary radiation displacements and damage in 3D geometry. Sci. Rep. 5(1), 18130 (2015)

T. Zhu, J. Li, A. Samanta, A. Leach, K. Gall, Temperature and strain-rate dependence of surface dislocation nucleation. Phys. Rev. Lett. 100(2), 025502 (2008)

Y. Zhang, H. Huang, Do twin boundaries always strengthen metal nanowires? Nanoscale Res. Lett. 4(1), 34 (2009)

S. Lee, A. Vaid, J. Im, B. Kim, A. Prakash, J. Guénolé, D. Kiener, E. Bitzek, S.H. Oh, In-situ observation of the initiation of plasticity by nucleation of prismatic dislocation loops. Nat. Commun. 11(1), 1 (2020)

S.W. Kaun, F. Wu, J.S. Speck, β-(AlxGa1−x)2O3/Ga2O3 (010) heterostructures grown on β-Ga2O3 (010) substrates by plasma-assisted molecular beam epitaxy. J. Vac. Sci. 33(4), 041508 (2015)

F.I. Allen, E. Kim, N.C. Andresen, C.P. Grigoropoulos, A.M. Minor, In situ TEM Raman spectroscopy and laser-based materials modification. Ultramicroscopy 178, 33 (2017)

O.C. Zienkiewicz, R.L. Taylor, D. Fox, The finite element method for solid and structural mechanics: seventh edition, 7th edn. (Butterworth-Heinemann, Oxford, 2013)

Acknowledgments

This work was primarily supported by the US Department of Energy, Office of Science, Office of Basic Energy Sciences, Materials Sciences and Engineering Division, under contract no. DE-AC02-05-CH11231 within the DamageTolerance in Structural Materials (KC 13) programme. S.Y.W. was supported by the National Science Foundation Graduate Research Fellowship (No. DGE 1752814). T.C.P. acknowledges funding from the DFG-project BR 5095/2-1 (Compressed sensing in ptychography and transmission electron microscopy). R.Z. and X.L. acknowledge funding from the US Office of Naval Research under Grant Nos. N00014-19-1-2376 and N00014-17-1-2283, respectively. The authors acknowledge support from the Molecular Foundry at Lawrence Berkeley National Laboratory, which is supported by the U.S. Department of Energy under Contract No. DE-AC02-05-CH11231. Pacific Northwest National Laboratory is operated for the U.S. DOE by Battelle Memorial Institute under Contract No. DE-AC05-76RLO1830. The authors thank Prof. Ju Li from MIT and Prof. Yongfeng Zhang from UW Madison for helpful discussions.

Funding

The authors declare no competing financial interests.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Supplementary Information

Below is the link to the electronic supplementary material.

Supplementary material 2 (MP4 13137 kb)

Supplementary material 3 (MP4 9930 kb)

Supplementary material 4 (MP4 8954 kb)

Supplementary material 5 (MP4 1929 kb)

Rights and permissions

About this article

Cite this article

Yang, Y., Wang, S.Y., Xiang, B. et al. Evaluating the effects of pillar shape and gallium ion beam damage on the mechanical properties of single crystal aluminum nanopillars. Journal of Materials Research 36, 2515–2528 (2021). https://doi.org/10.1557/s43578-021-00125-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-021-00125-5