Abstract

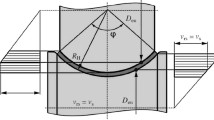

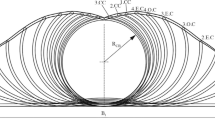

One of the most effective research techniques for studying any process is its physical modeling, during which it is possible to verify the data obtained earlier. The Metal Forming Laboratory of MISIS has an electric pipe-welded rig TESA 30–50 for studying continuous forming of longitudinal welded pipes of small and medium diameters. The zone of continuous pipe billet deformation is considered on the example of the first two stands of the pipe forming mill with the pass design of 50 × 1.5 mm. Based on the parameter calculations of real roll pass design, a scheme of contact interaction of the pipe billet with the first and second roll pass design is developed and sections of the deformation zone are determined along with their sizes. By analyzing the conditions of contact interaction of the pipe billet with roll pass designs, the parameters of the pipe billet in contact with the rolls of the first design are determined in seven sections with allowance for the continuous deformation in the mill forming line. Considering the data obtained, the calculation of longitudinal deformations for the edge and bottom of the pipe billet is carried out. The analysis of the results shows that the maximum longitudinal deformation occurred in the edge of the pipe billet in section B–B and is equal to 1.04%, and along the bottom of the pipe billet—0.92%. There is a coordinate grid applied to the pipe billet using a laser engraver. During the forming, the deviation of the trajectory of the pipe billet bottom from the horizontal axis is recorded, and the dimensions of the forming sections are determined. Comparison of theoretical and experimental values shows that the discrepancy between them does not exceed 7%.

Similar content being viewed by others

REFERENCES

Shatalov, R.L. and Medvedev, V.A., Regulation of the rolling temperature of blanks of steel vessels in a rolling-press line for the stabilization of mechanical properties, Metallurgist, 2020, vol. 63, nos. 9–10, pp. 1071–1076. https://doi.org/10.1007/s11015-020-00925-w

Aleshchenko, A.S., Budnikov, A.S., and Kharitonov, E.A., Metal forming during pipe reduction on three-high rolling mill, Steel Transl., 2019, vol. 49, pp. 661–666. https://doi.org/10.3103/S0967091219100024

Romantsev, B., Goncharuk, A., Aleshchenko, A., Gamin, Y., and Mintakhanov, M., Development of multipass skew rolling technology for stainless steel and alloy pipes’ production, Int. J. Adv. Manuf. Technol., 2018, vol. 97, nos. 9–12, pp. 3223–3230. https://doi.org/10.1007/s00170-018-2134-3

Abeyrathna, B., Rolfe, B., and Weiss, M., The effect of process and geometric parameters on longitudinal edge strain and product defects in cold roll forming, Int. J. Adv. Manuf. Technol., 2017, vol. 92, nos. 1–4, pp. 1–12. https://doi.org/10.1007/s00170-017-0164-x

Shatalov, R.L. and Medvedev, V.A., Effect of deformed workpiece temperature inhomogeneity on mechanical properties of thin-walled steel vessels during treatment in a rolling and pressing line, Metallurgist, 2019, vol. 63, nos. 1–2, pp. 76–182. https://doi.org/10.1007/s11015-019-00807-w

Kadach, M.V., Koshmin, A.N., Gamin, Y.V., and Romantsev, B.A., Obtaining steel tubular items of variable cross section along their length, Chern. Met., 2019, no. 4, pp. 37–41.

Kolikov, A.P., Zvonarev, D.Y., Ti, S.O., and Sido-rova, T.Y., Optimization of the processes of forming and welding of large-diameter pipes with the help of mathematic simulation. Metallurgist, 2020, vol. 64, nos. 1–2, pp. 153–168. https://doi.org/10.1007/s11015-020-00981-2

Osadchii, V.Ya., Gaas, E.A., Zvonarev, D.Yu., and Kolikov, A.P., Shaping of thick sheet in the production of welded large-diameter pipe, Steel Transl., 2014, vol. 44, no. 5, pp. 374–378. https://doi.org/10.3103/S0967091214050088

Kolikov, A.P., Leletko, A.S., Matveev, D.B., Kulyutin, S.A., and Kadil’nikov, S.V., Residual stress in welded pipes, Steel Transl., 2014, vol. 44, pp. 808–812. https://doi.org/10.3103/S0967091214110096

Shatalov, R.L., Shelest, A.E., and Medvedev, V.A., Electromagnetic device for nondestructive control of the mechanical properties of thin-walled steel vessels, Russ. Metall., 2020, vol. 2020, no. 3, pp. 259–264. https://doi.org/10.1134/S003602952003012X

Bidabadi, B., Moslemi, NaeiniH., Salmani, TehraniM., and Barghikar, H., Experimental and numerical study of bowing defects in cold roll-formed, U‑channel sections, J. Constr. Steel Res., 2016, vol. 118, pp. 243–253. https://doi.org/10.1016/j.jcsr.2015.11.007

Abedian, A., Shirani Bidabadi, B., and Shateri R., Numerical and experimental study of open die forging process design for producing heavy valves, Int. J. Interact. Des. Manuf., 2018, vol. 12, no. 1, pp. 49–61. https://doi.org/10.1007/s12008-017-0374-3

Mirzaali, M., Liaghat, G.H., Naeini, H.M., Seyedkashi, S.M.H., and Shojaee, K., Optimization of tube hydroforming process using simulated annealing algorithm, Procedia Eng., 2011, vol. 10, pp. 3012–3019. https://doi.org/10.1016/j.proeng.2011.04.499

Kasaei, M.M., Naeini, H.M., Tafti, R.A., and Tehrani, M.S., Prediction of maximum initial strip width in the cage roll forming process of ERW pipes using edge buckling criterion, J. Mater. Process. Technol., 2014, vol. 214, no. 2, pp. 190–199. https://doi.org/10.1016/j.jmatprotec.2013.08.012

Park, Y., Lee, C., Kim, J., Kim, D., Ahn, H., and Hwang, W., Parametric analysis for minimizing the edge waves in the roll forming, Int. J. Automot. Mech. Eng., 2018, vol. 15, no. 3, pp. 5480–5499. https://doi.org/10.15282/ijame.15.3.2018.6.0421

Budnikov, A.S., Kharitonov, E.A., Aleshchenko, A.S., and Iskhakov, R.V., Effect of plugless deformation in screw rolling three-roll mill on the change of tube wall thickness, Chern. Met., 2019, no. 12, pp. 41–45.

Shatalov, R.L., Medvedev, V.A., and Zagoskin, E.E., Determination of mechanical properties of steel thin-walled vessels by hardness after hot screw rolling with subsequent stamping and quenching, Chern. Met., 2019, no. 7, pp. 36–40.

Galkin, S.P., Romantsev, B.A., Ta, D.X., and Ga-min, Yu.V., Resource-saving technology for production of round bars from used shaft of rolling railroad stock, Chern. Met., 2018, no. 4, pp. 20–27.

Budnikov, A.S., Romantsev, B.A., and Kharitonov, E.A., Determination of rolls diameter for screw-rolling mills, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 2018, vol. 61, no. 9, pp. 683–688. https://doi.org/10.17073/0368-0797-2018-9-683-688

Aleshchenko, A.S., Gamin, Y.V., Chan, B.K., and Tsyutsyura, V.Y., Wear features of working tools during piercing of high-temperature alloys, Chern. Met., 2018, no. 8, pp. 63–70.

Romancev, B.A., Goncharuk, A.V., Aleshchenko, A.S., and Gamin, Y.V., Production of hollow thick-walled profiles and pipes made of titanium alloys by screw rolling, Russ. J. Non-Ferrous Met., 2015, vol. 56, no. 5, pp. 522–526. https://doi.org/10.3103/S1067821215050132

Lee, J., Kim, D., Quagliato, L., Kang, S., and Kim, N., Change of the yield stress in roll formed ERW pipes considering the Bauschinger effect, J. Mater. Process. Technol., 2017, vol. 244, pp. 304–313. https://doi.org/10.1016/j.jmatprotec.2017.01.022

Abeyrathna, B., Rolfe, B., Hodgson, P., and Weiss, M., Local deformation in roll forming, Int. J. Adv. Manuf. Technol., 2017, vol. 88, nos. 9–12, pp. 2405–2415. https://doi.org/10.1007/s00170-016-8962-0

Qiu, L., Zhang, S., Wang, Z., Hu, X., and Liu, X., A robust optimization design method for sheet metal roll forming and its application in roll forming circular cross-section pipe, Int. J. Adv. Manuf. Technol., 2019, vol. 103, nos. 5–8, pp. 2903–2916. https://doi.org/10.1007/s00170-019-03773-4

Paralikas, J., Salonitis, K., and Chryssolouris, G., Energy efficiency of cold roll forming process, Int. J. Adv. Manuf. Technol., 2013, vol. 66, nos. 9–12, pp. 1271–1284. https://doi.org/10.1007/s00170-012-4405-8

Safdarian, R. and Moslemi Naeini, H., The effects of forming parameters on the cold roll forming of channel section, Thin-Walled Struct., 2015, vol. 92, pp. 130–136. https://doi.org/10.1016/j.tws.2015.03.002

Nguyen, V.B., Wang, C.J., Mynors, D.J., English, M.A., and Castellucci, M.A., Dimpling process in cold roll metal forming by finite element modelling and experimental validation, J. Manuf. Process., 2014, vol. 16, no. 3, pp. 363–372. https://doi.org/10.1016/j.jmapro.2014.03.001

Sheikh, M.A. and Palavilayil, R.R., An assessment of finite element software for application to the roll-forming process, J. Mater. Process. Technol., 2006, vol. 180, nos. 1–3, pp. 221–232. https://doi.org/10.1016/j.jmatprotec.2006.06.009

Chan, C.L. and Khalid, Y.A., Finite element analysis of corrugated web beams under bending, J. Constr. Steel Res., 2002, vol. 58, no. 11, pp. 1391–1406. https://doi.org/10.1016/S0143-974X(01)00075-X

Heislitz, F. and Livatyali, H., Simulation of roll forming process with the 3-D FEM code PAM-STAMP, J. Mater. Process. Technol., 1996, vol. 59, nos. 1–2, pp. 59–67. https://doi.org/10.1016/0924-0136(96)02287-X

Li, Z.K., The detailed forming behavior of ERW tube- and pipe making process, Iron Steel Technol., 2018, vol. 15, no. 8, pp. 150–159.

Samusev, S.V., Fortunatov, A.N., and Frolova, N.A., and Pashkov N.G., Metody rascheta kalibrovok instrumenta i energosilovykh parametrov protsessa proizvodstva svarnykh trub v linii pressov i TESA. Sb. zadach (Methods for Calculating Tool Calibrations and Energy Parameters of Welded Pipes Production in the Line of Presses and ERW: Problem Book), Vyksa, Nizhni Novgorod oblast, Vyksunskii Filial, Mosk. Inst. Stalei i Splavov, 2006.

Potapov, I.N., Kolikov, A.P., and Druyan, V.M., Teoriya trubnogo proizvodstva. Uchebnik dlya vuzov (Theory of Pipe Production: Textbook for Universities), Moscow: Metallurgiya, 1991.

Svidovskii, F.G., Larin, Yu.T., Samusev, S.V., Pavlova, M.A., et al., Method for diagnostics and adjustment of rolls in stands of pipe-welding units, USSR Inventor’s Certificate no. 1745390, 1992.

Rymov, V.A., Polukhin, P.I., and Potapov, I.N., Sovershenstvovanie proizvodstva svarnykh trub (Improvement of Welded Pipes Production), Moscow: Metallurgiya, 1983.

Samusev, S.V. and Fortunatov, A.N., Metody rascheta napryazhenno-deformirovannogo sostoyaniya pri proizvodstve svarnykh trub v linii TESA. Sb. zadach (Methods for Calculating Stress- Stain State at Welded Pipes Production in the ERW Line: Problem Book), Vyksa, Nizhni Novgorod oblast, Vyksunskii Filial, Mosk. Inst. Stalei i Splavov, 2008.

Danchenko, V.N., Kolikov, A.P., Romantsev, B.A., and Samusev, S.V., Tekhnologiya trubnogo proizvodstva. Uchebnik dlya vuzov (Pipe Production Technology: Textbook for Universities), Moscow: Intermet Inzhiniring, 2002.

Samusev, S.V., Aleshchenko, A.S., and Fadeev, V.A., Simulation of the process of continuous forming of straight-seam welded pipes on the basis of TESA 10-50 TRAINER, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 2018, vol. 61, no. 5, pp. 378–384. https://doi.org/10.17073/0368-0797-2018-5-378-384

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by A. Kolemesin

About this article

Cite this article

Samusev, S.V., Kondrushin, A.V. & Fadeev, V.A. Deformation during Continuous Forming of Longitudinal Welded Pipes. Steel Transl. 52, 39–44 (2022). https://doi.org/10.3103/S0967091222010211

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091222010211