Abstract—

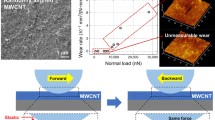

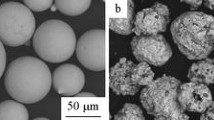

In the present study, TiN and CrN single-layer and TiN/CrN nanoscale multi-layer thin films have been deposited on 420C stainless steel (SS) substrate using a cathodic arc evaporation (CAE) method. The nanoindentation test showed that hardness of TiN/CrN nanoscale multi-layer thin film was 30 GPa that is harder than TiN (HTiN = 23 GPa) and CrN (HCrN = 19 GPa). Ball-on-disk tribometer and Rockwell-C indentation methods showed respectively better sliding wear performance for TiN/CrN nanoscale multi-layer coating and better adhesion strength for CrN single-layer coating in comparison to all samples. Finally it was found that the TiN/CrN nanoscale multi-layer thin film can be used for tribological applications on 420C SS where high hardness and wear resistance and low friction coefficients are essential.

Similar content being viewed by others

REFERENCES

Scheuer, C.J., Cardoso, R.P., and Zanetti, F.I., Low-temperature plasma carburizing of AISI 420 martensitic stainless steel: influence of gas mixture and gas flow rate, Surf. Coat. Technol., 2012, vol. 206, pp. 5085–5090.

Akbarzadeh, M., Shafyei, A., and Salimijazi, H.R., Characterization of TiN, CrN and (Ti, Cr) N coatings deposited by cathodic ARC evaporation, Int. J. Eng., 2014, vol. 27, no. 7, pp. 1127–1132.

Fukui, H., Evolutional history of coating technologies for cemented carbide inserts—chemical vapor deposition and physical vapor deposition, Sei Tech. Rev., 2016, no. 82, pp. 39–45.

Lin, S., Zhou, K., and Dai, M., Effects of surface roughness of substrate on properties of Ti/TiN/Zr/ZrN multilayer coatings, Trans. Nonferrous Met. Soc. China, 2015, vol. 2, pp. 451–456.

Mendibide, C., Steyer, P., Fontaine, J., and Goudeau, P., Improvement of the tribological behavior of PVD nanostratified TiN/CrN coatings—An explanation, Surf. Coat. Technol., 2006, vol. 201, pp. 4119–4124.

Thamotharan, J. and Sarala, R., Characterization of CrN/TiN PVD coatings on 316L stainless steel, Int. J. ChemTech. Res., 2014, vol. 6, no. 6, pp. 3284–3286.

Ormanova, M., Dechev, D., Bezdushnyi, R., and Petrov, P., Phase composition of multilayer system TiN/CrN deposited by DC magnetron sputtering, Bulg. Chem. Commun., 2017, vol. 49, pp. 98–102.

Lackner, J.M., Waldhauser, W., and Major, L., Nanocrystalline Cr/CrN and Ti/TiN multilayer coatings produced by pulsed laser deposition at room temperature, Bull. Pol. Acad. Sci.: Tech. Sci., 2006, vol. 54, no. 2, pp. 175–180.

Cao, J.L., Choy, K.L., and Sun, H.L., Syntheses of nano-multilayered TiN/TiSiN and CrN/CrSiN hard coatings, J. Coat. Technol. Res., 2011, vol. 8, pp. 283–288.

Mercado-Solis, R.D., Mata-Maldonado, J.G., Quinones-Salinas, M.A., et al., Micro-scale abrasive wear testing of CrN duplex PVD coating on pre-nitrided tool steel, Mater. Res., 2017, vol. 20, pp. 1092–1102.

Podchernyaeva, I.A., Yurechko, D.V., and Panashenko, V.M., Some trends in the development of wear-resistant functional coatings, Powder Metall. Met. Ceram., 2013, vol. 52, pp. 176–188.

Han, B., Wang, Z., and Devi, N., RBS depth profiling analysis of (Ti, Al) N/MoN and CrN/MoN multilayers, Nanoscale Res. Lett., 2017, vol. 12, pp. 161–169.

Bhushan, B., Depth-sensing nanoindentation measurement techniques and applications, Microsyst. Technol., 2017, vol. 23, pp. 1595–1649

Lackner, J., Major, L., and Kot, M., Microscale interpretation of tribological phenomena in Ti/TiN soft-hard multilayer coatings on soft austenite steel substrates, Bull. Pol. Acad. Sci.: Tech. Sci., 2011, vol. 59, pp. 343–355.

Bei, G.P., Gautheir-Brunet V., and Tromas, C., Synthesis, characterization, and intrinsic hardness of layered nanolaminate Ti3AlC2 and Ti3Al0.8Sn0.2C2 solid solution, J. Am. Ceram. Soc., 2012, vol. 95, pp. 102–107.

Sui, X., Liu, J., and Zhang, S., Microstructure, mechanical and tribological characterization of CrN/DLC/Cr–DLC multilayer coating with improved adhesive wear resistance, Appl. Surf. Sci., 2018, vol. 439, pp. 24–32.

Wang, J. and Zhou, Y., Recent progress in theoretical prediction, preparation, and characterization of layered ternary transition-metal carbides, Annu. Rev. Mater. Res., 2009, vol. 39, pp. 415–443.

Twu, M.J., Hu, C.C., and Liu, D.W., Effects of TiN, CrN and TiAlN coatings using reactive sputtering on the fatigue behaviour of AA2024 and medium carbon steel specimens, J. Exp. Nanosci., 2016, vol. 11, pp. 581–592.

Araujo, J.A., Souza, R.M., and Lima, N.B., Thick CrN/NbN multilayer coating deposited by cathodic arc technique, Mater. Res., 2017, vol. 20, pp. 200–209.

Cai, L., Huang, Z., and Hu, W., Fabrication, mechanical properties, and tribological behaviors of Ti2AlC and Ti2AlSn0.2C solid solutions, J. Adv. Ceram., 2017, vol. 6, pp. 90–99.

Kato, K., Wear in relation to friction—a review, Wear, 2000, vol. 241, pp. 151–157.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Gholamreza Faghani, Rabiee, S.M., Nourouzi, S. et al. Nanoscale Multi-Layer Thin Film Fabricated by Cathodic Arc Evaporation (CAE) Method. J. Superhard Mater. 42, 78–89 (2020). https://doi.org/10.3103/S1063457620020057

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1063457620020057