Abstract

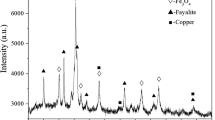

A copper removal process was carried out in a Pb-Cu alloy through sulfur powder injection of three different sizes (79.23, 202.83 and 597.15 μm) by a top submerged lance with nitrogen as carrying gas. The higher copper removal as CuS2 was obtained for the sulfur powder size of 79.23 μm, while the lowest copper removal efficiency was attained for the coarse particle size of 597.15 μm. The copper removal was explained according with a relationship between the residence and melting time. The sizes of 202.83 and 597.15 μm presented a longer residence time that promotes the sulfur coalescence and it is lost by burning. An injection-cooling trial was developed and a decoppering fraction of 0.29 with a sulfur efficiency of 72.98% in average was obtained for the fine size. The injection-cooling process represents an attractive route for secondary lead producers in the copper removal from molten lead.

Similar content being viewed by others

References

Kreusch, M., Ponte, M., Ponte, H., Kaminari, N., Marino, C., and Mymrin, V., Resources Conservation and Recycling, 2007, vol. 52, p. 368.

Prengaman, R.D., Journal Power Sources, 2005, vol. 144, p. 426.

Gutierrez, V.H., Cruz Ramirez, A., Vargas Ramirez, M., Palacios Beas, E., and Sanchez Alvarado, R.G., J. Transaction of Nonferrous Metals Society of China, 2014, vol. 24, p. 544.

Ramachandra, S., Resource Recovery and Recycling from Metallurgical Wastes: Waste Management Series 7, first edition, Elsevier B.V.: The Netherlands, 2006, p. 200.

Ellis, T. and Mirza, A., Journal of Power Sources, 2010, vol. 195, p. 4525.

Davey, T., The Physical Chemistry of Lead Refining, Lead-Zinc-Tin, first edition, USA: TMS, 1980, p. 477.

Davey, T., lead-zinc 2000, The Physical Chemistry of Lead Refining, Lead-Zinc-Tin, USA: TMS, 2000, p. 617.

Rabah, M., Barakat, M., and Farghaly, F., Journal Physicochemical Problems of Mineral Processing, 1999, vol. 33, p. 181.

Etsuji, K. and Hiromi, M., Copper removal from lead by dry method, Jpn. Kokai Tokkyo Koho JP, vol. 62 33, no. 728, p. 5.

Chakrabarti, D.J. and Laughlin, D.E., The Cu-S (Copper-sulfur) system, Bulletin of Alloy Phase Diagrams, 1983, vol. 4, no. 3, p. 254

Bither, T.A., Bouchard, R.J., Cloud, W.H., Donohue, P.C., and Siemons, W.J., Inorganic Chemical, 1968, vol. 7, pp. 2208–2220.

King, H.E. and Prewitt, Ch.T., American Mineralogist, 1979, vol. 64, pp. 1265–1271.

Goh, S.W., Buckley, A.N., and Lamb, R.N., Minerals Engineering, 2006, vol. 19, pp. 204–208.

Plascencia, G., Romero, A., Morales, R., Hallen, M., and Chavez, F., Canadian Metallurgical Quarterly, 2001, vol. 40, no. 3, p. 309.

Plascencia, G., Eliminación de Cobre, Níquel y Plata para el Reciclado de Baterías, [Dissertation] ESIQIE-IPN, Mexico, 1999, p. 28 [in Spanish].

Emi, T. and Yin, H., Injection metallurgy in steel industry current and future development, Proc. the Howard Worner International Symposium on Injection in Pyrometallurgy, TMS, 1996, p. 35.

Vargas, M., Romero, A., Morales, R., Hernandez, M., Chavez, F., and Castro, J., Steel Research, 2001, vol. 72, no. 5, p. 73.

Ohguchi, S. and Robertson, D., Ironmaking and Steelmaking, 1984, vol. 11, no. 5, p. 262.

Analytical Methods for Atomic Absorption Spectrometry, PERKIN-ELMER, 1994, pp. 73, 93.

Romero, A., Morales, R., Chávez, F., López, S., and Palafox, J., Eliminación de Cobre, Níquel y Plata del Plomo Líquido, Technical Report of the Project IPN-ENERTEC, DIM-ESIQIE-IPN, 1999, p. 15.

Nilmani, M. and Langberg, D., Metallurgical and Materials Transactions B, 1996, vol. 27B, p. 780.

Gaskell, D., An Introduction to Transport Phenomena in Materials Engineering, Ed. Macmillan Publishing Inc., 1992, p. 401.

Gutierrez, V.H., Vargas, M., Cruz, A., Romero, A., and Rivera, J.E., Materials Research, 2014, vol. 17, no. 4, pp. 838–850.

Calvert, L., National Research Council of Canada, Ottawa, Canada, AMMIAY, 1979, vol. 64, p. 1265.

Author information

Authors and Affiliations

Corresponding author

Additional information

The article is published in the original.

About this article

Cite this article

Gutierrez P., V.H., Cruz R., A., Romero S., J.A. et al. Analysis of the sulfur decoppering from molten lead by powder injection. Russ. J. Non-ferrous Metals 56, 251–260 (2015). https://doi.org/10.3103/S1067821215030086

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821215030086