Abstract

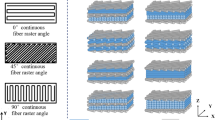

The subject of this study are tribological and strength properties of composites with matrix material in the form of thermoplastic plastics and a reinforcing material in the form of carbon fibers used in 3D printing technology—Fused Deposition Modeling. Simulation results of matrix material flow in the nozzle are presented. An analysis of the matrix material mixing process in the designed system was carried out and we developed our own conclusions. The article presents the method of forming this type of composite using a printhead at the stage of fabrication of an element. The possibility of modifying the geometrical distribution of reinforcing fibers in an element of the composite being tested by modifying the height of the layer of the applied material has been demonstrated. The relationship between the distance of subsequent carbon fiber bundles and the assumed height of the layer of applied material has been presented. Test results of abrasive wear and tensile strength of obtained materials with different percentages of reinforcing fibers are presented.

Similar content being viewed by others

REFERENCES

Eyers, D.R. and Potter, A.T., Industrial additive manufacturing: a manufacturing systems perspective, Comput. Ind., 2017, vols. 92–93, pp. 208–218.

Kumar, R., Singh, R., and Ahuja, I., Investigations of mechanical, thermal and morphological properties of FDM fabricated parts for friction welding applications, Measurement, 2018, vol. 120, pp. 11–20.

Parandoush, P. and Lin, D., A review on additive manufacturing of polymer-fiber composites, Compos. Struct., 2017, vol. 182, pp. 36–53.

Coricone, C., Gervaso, F., and Scalera, F., Highly loaded hydroxyapatite microsphere/PLA porous scaffolds obtained by fused deposition modeling, Ceram. Int., 2019, vol. 45, pp. 2803–2810.

Carminero, M.A., Chacón, J.M., García-Moreno, I., and Rodríguez, G.P., Impact damage resistance of 3D printed continuous fibre reinforced thermoplastic composites using fused deposition modelling, Composites, Part B, 2018, vol. 148, pp. 93–103.

Ibrahim, Y., Melenka, G., and Kempers, R., Fabrication and tensile testing of 3D printed continuous wire polymer composites, Rapid Prototyping J., 2018, vol. 24, pp. 1131–1141.

Prusinowski, A. and Kaczyński, R., Simulation of processes occurring in the extrusion head used in additive manufacturing technology, Acta Mech. Autom., 2017, vol. 11, pp. 317–321.

Prusinowski, A., Kaczyński, R., and Motyl, P., Analysis of FDM extrusion head design as application reinforced composite materials productions, in Advances in Mechanism and Machine Science, Mechanisms and Machine Science Series vol. 73, New York: Springer-Verlag, 2019, pp. 2769–2778.

Suresha, B., and Kumar, K.N.S., Investigations on mechanical and two-body abrasive wear behaviour of glass/carbon fabric reinforced vinyl ester composites, Mater. Des., 2009, vol. 30, pp. 2056–2060.

Panin, S.V., Nguyen Duc Anh, Kornienko, L.A., Alexenko, V.O., Buslovich, D.G., and Ovechkin, B.B., Wear-resistant polyetheretherketone composites: with carbon nano- and microfibers, Mater. Today, 2018, vol 5, pp. 25 976–25 982.

Wu, H., Zhu, L.-N., Yue, W., Fu, Z.-Q., and Kang, J.-J., Wear-resistant and hydrophobic characteristics of PTFE/CF composite coatings, Prog. Org. Coat., 2019, vol. 128, pp. 90–98.

Wilczewska, I., Kaczyński, R., and Sviridenok, A.I., Peculiarities of the wear mechanism of polymers reinforced with unidirectional carbon fibers, J. Frict. Wear, 2014, vol. 35, no. 6, pp. 449–454.

Funding

The work was partly supported by the project no. MB/MW/14/2017, which was carried out in the Faculty of Engineering Mechanics of Białystok Technological University.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by A. Muravev

About this article

Cite this article

Prusinowski, A., Kaczyński, R. Investigation of Tribological and Strength Properties of ABS/CF Fibrous Composites Formed in Fused Deposition Modeling. J. Frict. Wear 41, 318–325 (2020). https://doi.org/10.3103/S106836662004011X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S106836662004011X