Abstract

Objectives

This study aims to investigate the influence of thermocycling on the physical properties of different CAD/CAM restorative materials and assess their ability to maintain energy dissipation capacities and damping effects.

Materials and methods

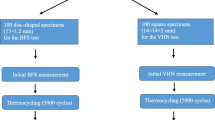

The results of a 3-point bending test were used to calculate flexural strength (FS), modulus of elasticity (ME), modulus of toughness (MT) and elastic recovery (ER) for three ceramic, twelve composite and five polymer-based materials. Specimens (n = 10, 4.0 × 1.5 × 17.0 mm3) were loaded until rupture after water storage (24 h; 37.0 ± 1.0 °C) or thermocycling (5000 cycles; 5–55 °C). Statistical data analysis was performed using parametric statistics (p = 0.05).

Results

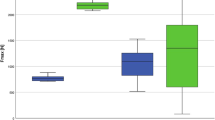

Thermocycling had no significant influence on any investigated properties of ceramic materials (p > 0.05). Hybrid composites showed significant differences between water storage and thermocycling (p < 0.05), with the exception of FS of Tetric CAD. Similarly, ME with AMBARINO High-Class, CERASMART, Tetric CAD and Vita Enamic and MT and ER with Paradigm and Tetric CAD were not affected. For polymer-based materials, significant differences were found with the exceptions of FS (PEEK-OPTIMA, Telio CAD), ME (M-PM Disc, PEEK-OPTIMA, Telio CAD, Vita CAD-Temp), MT (Telio CAD) and ER (Telio CAD).

Conclusions

The material properties of composite and polymer-based CAD/CAM materials were susceptible to degradation processes induced by thermocycling. Only Telio CAD and Tetric CAD showed no significant effects like all ceramic materials, thus preserving their inherent ability to elastically and plastically dissipate energy.

Clinical relevance

A careful material selection is advisable when planning CAD/CAM restorations as remarkable differences may exist in the durability of physical characteristics through the impact of water.

Similar content being viewed by others

Notes

Ashing in air (1 h, 700 ± 20 °C)

References

Zaytsev D, Panfilov P (2014) Deformation behavior of human enamel and dentin-enamel junction under compression. Mater Sci Eng C Mater Biol Appl 34:15–21. https://doi.org/10.1016/j.msec.2013.10.009/S0928-4931(13)00577-8

Kahler B, Swain MV, Moule A (2003) Fracture-toughening mechanisms responsible for differences in work to fracture of hydrated and dehydrated dentine. J Biomech 36:229–237

Jameson MW, Hood JA, Tidmarsh BG (1993) The effects of dehydration and rehydration on some mechanical properties of human dentine. J Biomech 26:1055–1065

Currey JD, Landete-Castillejos T, Estevez J, Ceacero F, Olguin A, Garcia A, Gallego L (2009) The mechanical properties of red deer antler bone when used in fighting. J Exp Biol 212:3985–3993. https://doi.org/10.1242/jeb.032292

Yan J, Daga A, Kumar R, Mecholsky JJ (2008) Fracture toughness and work of fracture of hydrated, dehydrated, and ashed bovine bone. J Biomech 41:1929–1936. https://doi.org/10.1016/j.jbiomech.2008.03.037

Nyman JS, Roy A, Shen X, Acuna RL, Tyler JH, Wang X (2006) The influence of water removal on the strength and toughness of cortical bone. J Biomech 39:931–938

Kruzic JJ, Nalla RK, Kinney JH, Ritchie RO (2003) Crack blunting, crack bridging and resistance-curve fracture mechanics in dentin: effect of hydration. Biomaterials 24:5209–5221

Ferracane JL (2006) Hygroscopic and hydrolytic effects in dental polymer networks. Dent Mater 22:211–222

Ferracane JL, Marker VA (1992) Solvent degradation and reduced fracture toughness in aged composites. J Dent Res 71:13–19

van Groeningen G, Jongebloed W, Arends J (1986) Composite degradation in vivo. Dent Mater 2:225–227

Lohbauer U, Frankenberger R, Kramer N, Petschelt A (2003) Time-dependent strength and fatigue resistance of dental direct restorative materials. J Mater Sci Mater Med 14:1047–1053

Lohbauer U, Belli R, Ferracane JL (2013) Factors involved in mechanical fatigue degradation of dental resin composites. J Dent Res 92:584–591

Hampe R, Lumkemann N, Sener B, Stawarczyk B (2018) The effect of artificial aging on Martens hardness and indentation modulus of different dental CAD/CAM restorative materials. J Mech Behav Biomed Mater 86:191–198

Al-Harbi FA, Ayad NM, ArRejaie AS, Bahgat HA, Baba NZ (2017) Effect of aging regimens on resin nanoceramic chairside CAD/CAM material. J Prosthodont 26:432–439

Sonmez N, Gultekin P, Turp V, Akgungor G, Sen D, Mijiritsky E (2018) Evaluation of five CAD/CAM materials by microstructural characterization and mechanical tests: a comparative in vitro study. BMC Oral Health 18:5

Egilmez F, Ergun G, Cekic-Nagas I, Vallittu PK, Lassila LVJ (2018) Does artificial aging affect mechanical properties of CAD/CAM composite materials. J Prosthodont Res 62:65–74

Tsujimoto A, Barkmeier WW, Takamizawa T, Latta MA, Miyazaki M (2017) Influence of thermal cycling on flexural properties and simulated wear of computer-aided design/computer-aided manufacturing resin composites. Oper Dent 42:101–110

Lauvahutanon S, Takahashi H, Shiozawa M, Iwasaki N, Asakawa Y, Oki M, Finger WJ, Arksornnukit M (2014) Mechanical properties of composite resin blocks for CAD/CAM. Dent Mater J 33:705–710

Blackburn C, Rask H, Awada A (2018) Mechanical properties of resin-ceramic CAD-CAM materials after accelerated aging. J Prosthet Dent 119:954–958

Porto T, Roperto R, Campos E, Porto-Neto S, Teich S (2016) Behavior of CAD/CAM materials after long thermocycling process. Dent Mater 32S:e33

Porto TS, Roperto RC, Akkus A, Akkus O, Teich S, Faddoul FF, Porto-Neto ST, Campos EA (2018) Effect of thermal cycling on fracture toughness of CAD/CAM materials. Am J Dent 31:205–210

Okada R, Asakura M, Ando A, Kumano H, Ban S, Kawai T, Takebe J (2018) Fracture strength testing of crowns made of CAD/CAM composite resins. J Prosthodont Res 62:287–292

Beer FP, Johnston ER, DeWolf JT, Mazurek DF (2015) Mechanics of materials. McGraw-Hill Inc., New York, p 759

Dyer SR, Lassila LV, Jokinen M, Vallittu PK (2005) Effect of cross-sectional design on the modulus of elasticity and toughness of fiber-reinforced composite materials. J Prosthet Dent 94:219–226

Smith ER, Allen MR (2013) Bisphosphonate-induced reductions in rat femoral bone energy absorption and toughness are testing rate-dependent. J Orthop Res 31:1317–1322

Niem T, Youssef N, Wostmann B (2019) Energy dissipation capacities of CAD-CAM restorative materials: a comparative evaluation of resilience and toughness. J Prosthet Dent 121:101–109

Shackelford JF (2015) Introduction to materials science for engineers. Pearson Education Inc., New York, p 168

Anusavice KJ (2003) Mechanical properties of dental materials. In: Anusavice KJ (ed) Phillips’ science of dental materials. WB Saunders Company, St. Louis, pp 73–101

Williams JG (2001) Fracture mechanics testing methods for polymers, adhesives and composites. Elsevier Science Ltd., Amsterdam

Grellmann W (2001) New developments in toughness evaluation of polymers and compounds by fracture machanics. In: Grellmann W, Seidler S (eds) Deformation and fracture behaviour of polymers. Springer, New York, pp 3–26

Cesar PF, Della Bona A, Scherrer SS, Tholey M, van Noort R, Vichi A, Kelly R, Lohbauer U (2017) ADM guidance-ceramics: fracture toughness testing and method selection. Dent Mater 33:575–584

Smith RL, Mecholsky JJ, Freiman SW (2009) Estimation of fracture energy from the work of fracture and fracture surface area: I. Stable crack growth. Int J Fract 156:97–102. https://doi.org/10.1007/s10704-009-9350-7

ISO (2015) ISO 6872, Dentistry—ceramic materials. International Organization for Standardization, Geneva

ASTM (2017) D790-17:2017, Standard test methods for flexural properties of unreinforced and reinforced plastics and electrical insulating materials. West Conshohocken, PA

ISO (2013) ISO 9513, Metallic materials—calibration of extensometer systems used in uniaxial testing. International Organization for Standardization, Geneva

Daemi H, Rajabi-Zeleti S, Sardon H, Barikani M, Khademhosseini A, Baharvand H (2016) A robust super-tough biodegradable elastomer engineered by supramolecular ionic interactions. Biomaterials 84:54–63. https://doi.org/10.1016/j.biomaterials.2016.01.025/S0142-9612(16)00033-8 [pii]

Kaizer MR, Almeida JR, Goncalves APR, Zhang Y, Cava SS, Moraes RR (2016) Silica coating of nonsilicate nanoparticles for resin-based composite materials. J Dent Res 95:1394–1400. https://doi.org/10.1177/0022034516662022

Lopez-Suevos F, Dickens SH (2008) Degree of cure and fracture properties of experimental acid-resin modified composites under wet and dry conditions. Dent Mater 24:778–785. https://doi.org/10.1016/j.dental.2007.09.006

Awada A, Nathanson D (2015) Mechanical properties of resin-ceramic CAD/CAM restorative materials. J Prosthet Dent 114:587–593. https://doi.org/10.1016/j.prosdent.2015.04.016/S0022-3913(15)00255-3

Tjandrawinata R, Irie M, Suzuki K (2005) Flexural properties of eight flowable light-cured restorative materials, in immediate vs 24-hour water storage. Oper Dent 30:239–249

Prakki A, Pereira PN, Kalachandra S (2009) Effect of propionaldehyde or 2,3-butanedione additives on the mechanical properties of Bis-GMA analog-based composites. Dent Mater 25:26–32. https://doi.org/10.1016/j.dental.2008.05.002

Peutzfeldt A, Asmussen E (1992) Modulus of resilience as predictor for clinical wear of restorative resins. Dent Mater 8:146–148

Lakens D (2013) Calculating and reporting effect sizes to facilitate cumulative science: a practical primer for t-tests and ANOVAs. Front Psychol 4

Kausch HH, Gensler R, Grein C, Plummer CJG, Scaramuzzino P (1999) Crazing in semicrystalline thermoplastics. J Macromol Sci Phys B 38:803–815. https://doi.org/10.1080/00222349908248140

Cohen J (1988) Statistical power analysis for the behavioral sciences. Lawrence Erlbaum Associates, New York

Chen PY, Lin AY, Lin YS, Seki Y, Stokes AG, Peyras J, Olevsky EA, Meyers MA, McKittrick J (2008) Structure and mechanical properties of selected biological materials. J Mech Behav Biomed Mater 1:208–226. https://doi.org/10.1016/j.jmbbm.2008.02.003

Winwood K, Zioupos P, Currey JD, Cotton JR, Taylor M (2006) The importance of the elastic and plastic components of strain in tensile and compressive fatigue of human cortical bone in relation to orthopaedic biomechanics. J Musculoskelet Neuronal Interact 6:134–141

Bijjargi S, Chowdhary R (2013) Stress dissipation in the bone through various crown materials of dental implant restoration: a 2-D finite element analysis. J Investig Clin Dent 4:172–177. https://doi.org/10.1111/j.2041-1626.2012.00149.x

Lauvahutanon S, Shiozawa M, Takahashi H, Iwasaki N, Oki M, Finger WJ, Arksornnukit M (2017) Discoloration of various CAD/CAM blocks after immersion in coffee. Restor Dent Endod 42:9–18

Ferracane JL, Berge HX, Condon JR (1998) In vitro aging of dental composites in water—effect of degree of conversion, filler volume, and filler/matrix coupling. J Biomed Mater Res 42:465–472

Ferracane JL, Condon JR (1991) Degradation of composites caused by accelerated aging. J Dent Res 70(Spec Iss 1):480. www.iadr.org

Stawarczyk B, Ender A, Trottmann A, Ozcan M, Fischer J, Hammerle CH (2012) Load-bearing capacity of CAD/CAM milled polymeric three-unit fixed dental prostheses: effect of aging regimens. Clin Oral Investig 16:1669–1677. https://doi.org/10.1007/s00784-011-0670-4

Edelhoff D, Schraml D, Eichberger M, Stawarczyk B (2016) Comparison of fracture loads of CAD/CAM and conventionally fabricated temporary fixed dental prostheses after different aging regimens. Int J Comput Dent 19:101–112

Wimmer T, Ender A, Roos M, Stawarczyk B (2013) Fracture load of milled polymeric fixed dental prostheses as a function of connector cross-sectional areas. J Prosthet Dent 110:288–295

Mohsen NM, Craig RG, Filisko FE (2001) The effects of moisture on the dielectric relaxation of urethane dimethacrylate polymer and composites. J Oral Rehabil 28:376–392

Soderholm KJ (1981) Degradation of glass filler in experimental composites. J Dent Res 60:1867–1875

Schrader ME, Block A (1971) Tracer study of kinetics and mechanism of hydrolytically induced interfacial failure. J Polym Sci Part C Polymer Symposium:281–291

Ishida H, Miller JD (1984) Substrate effects on the chemisorbed and physisorbed layers of methacryl silane modified particulate minerals. Macromolecules 17:1659–1666. https://doi.org/10.1021/ma00139a004

Plueddemann EP (1970) Adhesion through silane coupling agents. J Adhes 2:184–201. https://doi.org/10.1080/0021846708544592

Ivoclar Vivadent (2018) Tetric CAD: scientific documentation. Ivoclar Vivadent AG, Schaan. http://www.ivoclarvivadent.com/en/download-center/scientific-documentations. Accessed Jul 2018

Ivoclar Vivadent (2010) Telio CAD: scientific documentation. Ivoclar Vivadent AG, Schaan. http://www.ivoclarvivadent.com/en/download-center/scientific-documentations. Accessed 2010

VITA Zahnfabrik (2019) VITA ENAMIC: technical and scientific documentation. VITA Zahnfabrik H. Rauter GmbH & Co. KG, Bad Säckingen. https://mam.vita-zahnfabrik.com/portal/ecms_mdb_download.php?id=82333&sprache=en&fallback=&rechtsraum=&cls_session_id=&neuste_version=1. Accessed Feb 2019

Acknowledgements

The authors thank Antje Hübner for her technical assistance in sample preparation and data acquisition. We also thank Juvora Ltd. for donating PEEK-Optima. In addition, we gratefully acknowledge the support of our biostatistician Dr. Johannes Herrmann.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial or not-for-profit sectors. No external funding; the study is solely based on the department budgets of the authors.

Author information

Authors and Affiliations

Author notes

Nivin Youssef is deceased. This paper is dedicated to her memory.

- Nivin Youssef

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed consent

For this type of study, formal consent is not required.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Niem, T., Youssef, N. & Wöstmann, B. Influence of accelerated ageing on the physical properties of CAD/CAM restorative materials. Clin Oral Invest 24, 2415–2425 (2020). https://doi.org/10.1007/s00784-019-03101-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00784-019-03101-w