Abstract

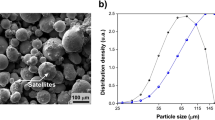

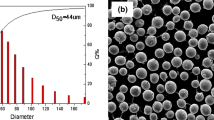

In this work, 18Ni300 maraging steel was successfully fabricated, for the first time, by a laser cladding technique under atmospheric condition. The effects of different aging times (1, 3, 6, and 9 h) at 500 °C on the microstructure and mechanical properties of the as-cladded 18Ni300 maraging steel were carefully characterized and analyzed. The microhardness and tensile strength increase with increasing aging time up to 6 h, and subsequently, decrease with the time extending to 9 h. On the contrary, the elongation is shown a reverse trend. The original 18Ni300 maraging steel exhibits cellular microstructure with an average grain size of 2 µm, composed of martensite and nano-Ti2N particles. After aging treatment, Ni-rich nano-precipitates (Ni3(Mo,Ti) and Ni(Mo,Ti)) together with reverted austenite were formed and promoted with the extension of aging time. The optimal comprehensive performance of the 18Ni300 maraging steel can be obtained by aging 3 h at 500°C, with microhardness of 509 HV0.2, ultimate tensile strength of 1686 MPa, and elongation of 11.5%, respectively. The microstructural mechanisms accounting for the property changes are discussed in detail.

Similar content being viewed by others

References

Pardal JM, Tavares SSM, Terra VF, Da Silva MR, Dos Santos DR (2005) Modeling of precipitation hardening during the aging and overaging of 18Ni-Co-Mo-Ti maraging 300 steel. J Alloys Compd 393:109–113

Song J, Tang Q, Feng Q, Ma S, Setchi R, Liu Y, Zhang M (2019) Effect of heat treatment on microstructure and mechanical behaviours of 18Ni-300 maraging steel manufactured by selective laser melting. Opt Laser Technol 120:105725

Bai Y, Yang Y, Wang D (2017) Influence mechanism of parameters process and mechanical properties evolution mechanism of maraging steel 300 by selective laser melting. Mater Sci Eng A 703:116–123

Tan C, Zhou K, Ma W, Zhang P, Liu M, Kuang T (2017) Microstructural evolution nanoprecipitation behavior and mechanical properties of selective laser melted high-performance grade 300 maraging steel. Mater Des 134:23–34

Yin S, Chen C, Yan X (2018) The influence of aging temperature and aging time on the mechanical and tribological properties of selective laser melted maraging 18Ni-300 steel. Addi Manuf 22:592–600

Rao MN (2006) Progress in understanding the metallurgy of 18% nickel maraging steels. Int J Mater Res 97:1594–1607

Casati R, Lemke JN, Tuissi A (2016) Aging behaviour and mechanical performance of 18-Ni 300 steel processed by selective laser melting. Met 6:218

Li K, Wei L, An B, Yu B, Misra RDK (2019) Aging phenomenon in low lattice-misfit cobalt-free maraging steel: microstructural evolution and strengthening behavior. Mater Sci Eng A 739:445–454

Suryawanshi J, Prashanth KG, Ramamurty U (2017) Tensile, fracture, and fatigue crack growth properties of a 3D printed maraging steel through selective laser melting. J Alloys Compd 725:355–364

Kempen K, Yasa E, Thijs L (2011) Microstructure and mechanical properties of selective laser melted 18Ni-300 steel. Phys Procedia 12:255–263

Pardal JM, Tavares SSM, Fonseca MC (2006) Study of the austenite quantification by X-ray diffraction in the 18Ni-Co-Mo-Ti maraging 300 steel. Mater Sci 41:2301–2307

Avelino AF, Araújo WS, Dias DF, dos Santos LPM, Correia AN (2018) Corrosion investigation of the 18Ni 300 grade maraging steel in aqueous chloride medium containing H2S and CO2. Electrochim Acta 286:339–349

Jägle EA, Choi PP, Van Humbeeck J, Raabe D (2014) Precipitation and austenite reversion behavior of a maraging steel produced by selective laser melting. J Mater Res 29(17):2072

Mutua J, Nakata S, Onda T, Chen ZC (2018) Optimization of selective laser melting parameters and influence of post heat treatment on microstructure and mechanical properties of maraging steel. Mater Des 139:486–497

Demir AG, Previtali B (2017) Investigation of remelting and preheating in SLM of 18Ni300 maraging steel as corrective and preventive measures for porosity reduction. Int J Adv Manuf Technol 93:2697–2709

Yao Y, Huang Y, Chen B (2018) Influence of processing parameters and heat treatment on the mechanical properties of 18Ni300 manufactured by laser based directed energy deposition. Opt Laser Technol 105:171–179

Li X, Yin Z (1995) Reverted austenite during aging in 18Ni (350) maraging steel[J]. Mater Lett 24(4):239–242

Zhu H, Li Y, Li B (2018) Effects of low-temperature tempering on microstructure and properties of the laser-cladded AISI 420 martensitic stainless steel coating. Coat 8:451

Beres M, Wu L, Santos LPM (2017) Role of lattice strain and texture in hydrogen embrittlement of 18Ni (300) maraging steel. Int J Hydrogen Energy 42:14786–14793

Li BC, Zhu HM, Qiu CJ, Zhang DK (2020) Development of high strength and ductile martensitic stainless steel coatings with Nb addition fabricated by laser cladding. J Alloys Compd 832:154985

Hu W, Zhu H, Hu J (2020) Influence of vanadium microalloying on microstructure and property of laser-cladded martensitic stainless steel coating. Mater 13:826

Liu L, Shen HH, Liu XZ (2016) Wear resistance of TiN (Ti2N)/Ti composite layer formed on C17200 alloy by plasma surface Ti-alloying and nitriding. Appl Surf Sci 388:103–108

Hsieh CF, Jou S (2006) Titanium nitride electrodes for micro-gap discharge. Microelectron J 37:867–870

Huang X, Hansen N, Tsuji N (2006) Hardening by annealing and softening by deformation in nanostructured metals. Sci 312:249–251

Wang YM, Cheng S, Wei QM (2004) Effects of annealing and impurities on tensile properties of electrodeposited nanocrystalline Ni. Scripta Mater 51:1023–1028

Allam T, Pradeep KG, Köhnen P, Marshal A, Schleifenbaum JH, Haase C (2020) Tailoring the nanostructure of laser powder bed fusion additively manufactured maraging steel. Addi Manuf 36:101561

Hengsbach F, Koppa P, Duschik K (2017) Duplex stainless steel fabricated by selective laser melting-microstructural and mechanical properties. Mater Des 133:136–142

Liu H, Liu J, Li X, Chen P, Yang H, Hao J (2020) Effect of heat treatment on phase stability and wear behavior of laser clad AlCoCrFeNiTi0.8 high-entropy alloy coatings. Surf Coat Technol 392:125758

Schnitzer R, Radis R, Nöhrer M (2010) Reverted austenite in PH 13–8 Mo maraging steels. Mater Chem Phys 122:138–145

Sinha PP, Tharian KT, Sreekumar K (1998) Effect of aging on microstructure and mechanical properties of cobalt free 18% Ni (250 grade) maraging steel. Mater Sci Technol 14:1–9

Das A, Das SK, Tarafder S (2009) Correlation of fractographic features with mechanical properties in systematically varied microstructures of Cu-strengthened high-strength low-alloy steel. Metall Mater Trans A 40:3138

Das A, Tarafder S (2008) Geometry of dimples and its correlation with mechanical properties in austenitic stainless steel. Scripta Mater 59:1014–1017

Funding

This work was financially supported by Open Research Fund of State Key Laboratory of High Performance Complex Manufacturing, Central South University (No. Kfkt2018-06) and National Key Research and Development Program of China (No. 2018YFB1105803).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: David Balloy.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhu, H.M., Zhang, J.W., Hu, J.P. et al. Effects of aging time on the microstructure and mechanical properties of laser-cladded 18Ni300 maraging steel. J Mater Sci 56, 8835–8847 (2021). https://doi.org/10.1007/s10853-021-05841-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-05841-1