Abstract

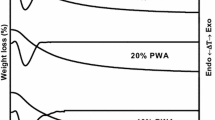

Al2O3@SiO2 core–shell catalysts were synthesized by sol–gel method. The core size’control was provided by using of polyethylene glycol (PEG) and glycerol. The shell thickness was optimized by using the different amount of tetraethylorthosilicate (TEOS). The formation of core and shell structures in catalysts was seen in high resolution transmission electron microscopy (HRTEM) images. In some catalysts, the use of PEG caused to formation of a more monodisperse core structure. The particle size of catalysts was observed in the range of 8–12 nm. The BET (Brunauer–Emmett–Teller) surface area and total pore volume of catalysts ranged 440–1014 m2/g and 1.28–2.57 cm3/g, respectively. In addition, pore diameter reached up to 25 nm. The use of PEG and glycerol improved textural properties. While BET surface area and total pore volume values decreased by the increase of TEOS amount, shell thickness increased a little. Fourier transform infrared (FTIR) spectrums of the pyridine adsorbed catalysts revealed the presence of Lewis and Brønsted acid sites in the catalysts. The catalysts were tested in the degradation of polylactic acid (PLA) by using thermogravimetric analysis (TGA) technique. TGA results showed the degradation temperature of PLA decreased from 353 to 321 °C in the presence of catalysts. Activation energy values were calculated using Flynn–Wall–Ozawa method. The activation energy was reduced from 337 to 199 kJ/mol. Pore structure, particle size and acidity of catalysts significantly affected the degradation performance.

Similar content being viewed by others

References

Praphulla T, Chandan G (2010) Effect of metal oxide catalysts on degradation of waste polystyrene in hydrogen at elevated temperature and pressure in benzene solution. J Polym Environ 18:298–307

Mierzwa-Hersztek M, Gondek K, Kopeć M (2019) Degradation of polyethylene and biocomponent-derived polymer materials: an overview. J Polym Environ 27:600–611

Attique S, Batool M, Yaqub M, Gregory DH, Wilson C, Goerke O, Shah AT (2020) Synthesis and catalytic performance of cesium and potassium salts of aluminum substituted tungstoborate for pyrolysis of polyethylene waste to petrochemical feedstock. Mater Chem Phys 246:122781

Román-Ramírez LA, Powders M, McKeown P, Jones MD, Wood J (2020) Ethyl lactate production from the catalytic depolymerisation of post-consumer poly(lactic acid). J Polym Environ. https://doi.org/10.1007/s10924-020-01824

Lv S, Zhang Y, Tan H (2019) Thermal and thermo-oxidative degradation kinetics and characteristics of poly (lactic acid) and its composites. Waste Manage 87:335–344

Pierella LB, Renzini S, Anunziata OA (2005) Catalytic degradation of high density polyethylene over microporous and mesoporous materials. Microporous Mesoporous Mater 81:155–159

Silva AOS, Souza MJB, Pedrosa AMG, Coriolano ACF, Fernandes VJ, Araujo AS (2017) Development of HZSM-12 zeolite for catalytic degradation of high-density polyethylene. Microporous Mesoporous Mater 244:1–6

Singhal R, Singhal C, Upadhyayula S (2010) Thermal-catalytic degradation of polyethylene over silicoaluminophosphate molecular sieves—a thermogravimetric study. J Analyt Appl Pyrol 89:313–317

Panda AK, Singh RK (2011) Catalytic performances of kaoline and silica alümina in the thermal degradation of polypropylene. J Fuel Chem Technol 39:198–202

Lin S, Liu R, Li N, Guoc P, Shi L (2017) A controlled alkaline treatment of Al-SBA-15: a facile route to adjust the chemical composition and synthesize an ordered mesoporous carbon material, CMK-3, possessing strong pressure resistant capability. New J Chem 41:7634–7642

Oh D, Lee HW, Kim YM, Park YK (2018) Catalytic pyrolysis of polystyrene and polyethylene terephthalate, over Al-MSU-F. Energy Procedia 144:111–117

Joo SH, Park JY, Tsung CK, Yamada Y, Yang P, Somorjai GA (2009) Thermally stable Pt/mesoporous silica core–shell nanocatalysts for high-temperature reactions. Nat Mater 8:126–131

Jankiewicz BJ, Jamiola D, Choma J, Jaroniec M (2012) Silica–metal core–shell nanostructures. Adv Colloid Interface Sci 170:28–47

Wang Y, Liu J, Wang P, Werth CJ, Strathmann TJ (2014) Palladium nanoparticles encapsulated in core−shell silica: a structured hydrogenation catalyst with enhanced activity for reduction of oxyanion water pollutants. ACS Catal 4:3551–3559

Sydorchuk V, Zazhigalov V, Khalameida S, Diyuk E, Skubiszewska-Zieba J, Leboda R, Kuznetsova L (2010) Solvothermal synthesis of vanadium phosphates in the form of xerogels, aerogels and mesostructures. Mater Res Bull 45:1096–1105

Jung IK, Gurav JL, Ha TJ, Choi SG, Baek S, Park HH (2012) The properties of silica aerogels hybridized with SiO2 anoparticles by ambient pressure drying. Ceram Int 38:105–108

Kido Y, Nakanishi K, Miyasaka A, Kanamori K (2012) Synthesis of monolithic hierarchically porous iron-based xerogels from iron (III) salts via an epoxide-mediated sol−gel process. Chem Mater 24:2071–2077

Li SH, Lin WG, Huang BC, Wang LJ, Gu WB, Wang WM, Yang ZY, Wang Y, Zhu JH (2016) Capturing nitrosamines in aqueous solution by composited super-hydrophobic silicic xerogel. Microporous Mesoporous Mater 227:161–168

Jin H, Ji Z, Li Y, Liu M, Yuan J, Xu C, Hou S (2014) The preparation of a core/shell structure with alumina coated spherical silica powder. Colloids Surf A 441:170–177

Pu J, Nishikado K, Wang N, Nguyen TT, Maki T, Qian EW (2018) Core-shell nickel catalysts for the steam reforming of acetic acid. Appl Catal B 224:69–79

Liu H, Guo Y, Wang X, Liang X, Liu X (2015) Preparation of an Al2O3/SiO2 core–shell composite material for solid phase extraction of flavonoids. Anal Methods 7:3486–3492

Das H, Debnath N, Arai T, Kawaguchi T, Sakamoto N, Shinozaki K, Suzuki H, Wakiya N (2019) Superparamagnetic magnesium ferrite/silica core-shell nanospheres: a controllable SiO2 coating process for potential magnetic hyperthermia application. Adv Powder Technol 30:3171–3181

Lucchini MA, Testino A, Kambolis A, Proff C, Ludwig C (2016) Sintering and coking resistant core–shell microporous silica–nickel nanoparticles for CO methanation: towards advanced catalysts production. Appl Catal B 182:94–101

Liu H, Cao C, Li P, Yu Y, Song W (2014) Core-shell structured nanospheres with mesoporous silica shell and Ni core as a stable catalyst for hydrolytic dehydrogenation of ammonia borane. J Energy Chem 23:50–56

Lowell S, Shields JE, Thomas MA, Thommes M (2006) Characterization of Porous Solids and Powders: Surface Area and Pore Size and Density. Kluwer Academic Publishers, NewYork

Tran HN, Lee CK, Nguyen TV, Chao HP (2018) Saccharide-derived microporous spherical biochar prepared from hydrothermal carbonization and different pyrolysis temperatures: synthesis, characterization, and application in water treatment. Environ Technol 39(21):2747–2760

Mejia-Ariza R, Huskens J (2016) The effect of PEG length on the size and guest uptake of PEG-capped MIL-88A particles. J Mater Chem B 4:1108–1115

Kathiresan S, Lasekan O (2019) Effects of glycerol and stearic acid on the performance of chickpea starch-based coatings applied to fresh-cut papaya. Cyta J Food 17:365–374

Yao LH, Li YX, Zhao J, Ji WJ, Au CT (2010) Core–shell structured nanoparticles (M@SiO2, Al2O3, MgO; M= Fe Co, Ni, Ru) and their application in COx-free H2 production via NH3 decomposition. Catal Today 158:401–408

Asgari M, Soleymani M, Miri T, Barati A (2019) A robust method for fabrication of monodisperse magnetic mesoporous silica nanoparticles with core-shell structure as anticancer drug carriers. J Mol Liq 292:111367

Midor AW, Falkowski P, Szafran M (2020) Influence of core-shell structure on the cure depth in photopolymerizable alumina dispersion. Int J Appl Ceram Technol 17:248–254

Inui T, Anpo M, Izui K, Yanagida S, Yamaguchi T (1998) Advanced in chemical conversions for mitigating carbondioxide. Studies in Surface Science and Catalysis, Elsevier Science B.V. 114

Stolarski M, Walendziewski J, Steininger M, Pniak B (1999) Synthesis and characteristic of silica aerogels. Appl Catal A 177:139–148

Oliveira DM, Andrada AS (2019) Synthesis of ordered mesoporous silica MCM-41 with controlled morphology for potential application in controlled drug delivery systems. Cerâmica 65:170–179

Lee DW, Jin MH, Park JC, Lee CH, Oh D, Lee SW, Park JW, Park JS (2015) Waste-glycerol-directed synthesis of mesoporous silica and carbon with superior performance in room-temperature hydrogen production from formic acid. Sci Rep 5:15931

Firmansyah DA, Sullivan K, Lee KS, Kim YH, Zahaf R, Zachariah MR, Lee D (2012) Microstructural behavior of the alumina shell and aluminum core before and after melting of aluminum nanoparticles. J Phys Chem C 116:404–411

Akti F (2020) Effect of kaolin on aluminum loading success in synthesis of Al-SBA-15 catalysts: activity test in ethanol dehydration reaction. Microporous Mesoporous Mater 294:109894

Saikia BJ, Parthasarathy G (2010) Fourier transform infrared spectroscopic characterization of kaolinite from Assam and Meghalaya, northeastern India. J Mod Phys 1:206–210

Qoniah I, Prasetyoko D, Bahruji H, Triwahyono S, Jalil AA, Suprapto H, Purbaningtias TE (2015) Direct synthesis of mesoporous aluminosilicates from Indonesian kaolin clay without calcination. Appl Clay Sci 118:290–294

Safavi A, Iranpoor N, Saghir N, Momeni S (2006) Glycerol–silica gel: a new solid sorbent for preconcentration and determination of traces of cobalt (II) ion. Anal Chim Acta 569:139–144

Tomul F, Arslan Y, Tran HN (2019) Metal-loaded carbonated mesoporous calcium silicates: synthesis, characterization, and application for diclofenac removal from water. Ind Eng Chem Res 58:22084–22093

Frost RL, Kloprogge JT, Ding Z (2002) Near-infrared spectroscopic study of nontronites and ferruginous smectite. Spectrochim Acta A 58:1657–1668

Nawrocki J (1997) The silanol group and its role in liquid chromatography. J Chromatogr A 779:29–71

Mourhly A, Khachani M, El Hamidi A, Kacimi M, Halim M, Arsalane S (2015) The synthesis and characterization of low-cost mesoporous silica SiO2 from local pumice rock. Nanomater Nanotechnol 5:35

Aghazadeh M, Karım R, Abdulrahman R, Sultan MT, Johnson SK, Paykary M (2018) Effect of glycerol on the physicochemical properties of cereal starch films. Czech J Food Sci 36:403–409

Akti F, Balci S, Dogu T (2019) Role of synthesis media on properties of tin and copper incorporated SBA-15 catalysts and their activity in selective oxidation of ethanol. Mater Chem Phys 223:249–259

Ding Y, Dan H, Dong X, Xian Q, Wang Y, Lu X (2017) A convenient solvotermal method to synthesize highly ordered mesoporous silica SBA-15 with high loading of amino groups. Mater Chem Phys 192:156–160

Socci J, Osatiashtiani A, Kyriakou G, Bridgwater T (2019) The catalytic cracking of sterically challenging plastic feedstocks over high acid density Al-SBA-15 catalysts. Appl Catal A 570:218–227

Filho JGAP, Graciliano EC, Silva AOS, Souza MJB, Araujo AS (2005) Thermo gravimetric kinetics of polypropylene degradation on ZSM-12 and ZSM-5 catalysts. Catal Today 107–108:507–512

Lee HW, Kim YM, Lee B, Kim S, Jae J, Jung SC, Kim TW, Park YK (2018) Catalytic copyrolysis of torrefied cork oak and high densitypolyethylene over a mesoporous HY catalyst. Catal Today 307:301–307

Susastriawan AAP, Purnomo SA (2020) Experimental study the influence of zeolite size on low-temperature pyrolysis of low-density polyethylene plastic waste. Therm Sci Eng Prog 17:100497

Vyazovkina S, Burnham AK, Criado JM, Pérez-Maqueda LA, Popescu C, Sbirrazzuoli N (2011) ICTAC kinetics committee recommendations for performing kinetic computations on thermal analysis data. Thermochim Acta 520:1–19

Yuzay IE, Auras R, Soto-Valdez H, Selke S (2010) Effects of synthetic and natural zeolites on morphology and thermal degradation of poly(lactic acid) composites. Polym Degrad Stab 95:1769–1777

Han W, Ren J, Xuan H, Ge L (2018) Controllable degradation rates, antibacterial, free-standing and highly transparent films based on polylactic acid and chitosan. Colloid Surf A 541:128–136

Acknowledgements

This work was supported by the Scientific Research Project Department of Hitit University (MUH19001.19.009).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Akti, F. Catalytic Degradation of Polylactic Acid over Al2O3@SiO2 Core–Shell Catalysts. J Polym Environ 29, 2236–2247 (2021). https://doi.org/10.1007/s10924-020-02041-x

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-020-02041-x