Abstract

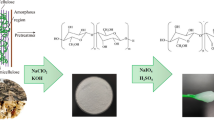

Recently, cellulose nanocrystals (CNCs) have captured the interest of researchers and industries. In this study, CNCs were isolated from four abundant lignocellulosic byproducts: teff (Eragrostis tef, Poaceae) straw, enset (Ensete ventricosum, Musaceae) fiber (EF), sugarcane (Saccharum officinarum, Poaceae) bagasse and coffee (Coffea arabica, Rubiaceae) hull (CH). Cellulose fibers were obtained using chlorine-free extraction with 5% sodium hydroxide pretreatment followed by delignification (with formic acid, acetic acid and hydrogen peroxide) and bleaching (with alkaline hydrogen peroxide). CNCs were then isolated following hydrolysis of the cellulose fibers with 64% sulfuric acid. The as-obtained CNCs were investigated and characterized in terms of yield, crystallinity, chemical functionality, morphology, particle size, zeta potential (ZP) and thermal stability. The CNCs displayed a typical crystal lattice of Iβ-type based on XRD patterns, d-spacings and Z-values. The highest yield (~ 70%), CrI (~ 86%), and crystal size (~ 6 nm) were observed in EF–CNCs, and the least in CH–CNCs (yield: ~ 25%, CrI: ~ 77%, crystal size: ~ 4 nm). FTIR spectra of all CNCs indicated typical chemical composition of cellulose. TEM observations revealed that the CNCs were needle-shaped nanoscale structures with different aspect ratios (17.32–36.67) and dimensions (average length: 154.28–193.06 nm; diameter: 5.16–11.79 nm), while the DLS measurements provided the hydrodynamic sizes, 96.96–184.90 nm. The thermal studies by TGA/DTG revealed the CNCs had a two-step decomposition process at Tmax 215–225 °C and 340–355 °C. This study showed that the CNCs isolated exhibited high crystallinity, aspect ratio, colloidal and thermal stability although differences were observed due to variations in cellulose sources.

Similar content being viewed by others

Abbreviations

- C1 and C2:

-

Cellulose fibres extracted with extraction Conditions 1 and 2, respectively

- CC:

-

Commercial cellulose

- CC-CNCs:

-

Cellulose nanocrystals isolated from commercial cellulose

- CH:

-

Coffee hull

- CNCs-C1 and CNCs-C2:

-

Cellulose nanocrystals isolated from C1 and C2, respectively

- CrI(s):

-

Crystallinity index/indexes

- DLS:

-

Dynamic light scattering

- DTG:

-

Differential thermo gravimetry

- EF:

-

enset Fiber

- FTIR:

-

Fourier-Transform Infrared spectroscopy

- HA:

-

Hermans et al. approach

- SA:

-

Segal et al. approach

- SB:

-

Sugarcane bagasse

- TEM:

-

Transmission electron microscopy

- TGA:

-

Thermogravimetric analysis

- TS:

-

teff Straw

- X200 :

-

The proportion of crystallite interior chains for the 200 plane

- XRD:

-

X-ray diffraction

- ZP:

-

Zeta potential

- Δd/d200 :

-

The fractional variation in the plane spacing for the 200 plane

- τ200 :

-

Average thickness (size) of cellulose crystallites for the 200 plane

References

Poletto M, Ornaghi Júnior HL, Zattera AJ (2014) Native cellulose: Structure, characterization and thermal properties. Materials (Basel) 7:6105–6119. https://doi.org/10.3390/ma7096105

El Achaby M, El Miri N, Hannache H et al (2018) Production of cellulose nanocrystals from vine shoots and their use for the development of nanocomposite materials. Int J Biol Macromol 117:592–600. https://doi.org/10.1016/j.ijbiomac.2018.05.201

Adel AM, Abd El-Wahab ZH, Ibrahim AA, Al-Shemy MT (2011) Characterization of microcrystalline cellulose prepared from lignocellulosic materials. Part II: physicochemical properties. Carbohydr Polym 83:676–687. https://doi.org/10.1016/j.carbpol.2010.08.039

do Nascimento DM, Dias AF, de Araújo Junior CP et al (2016) A comprehensive approach for obtaining cellulose nanocrystal from coconut fiber. Part II: environmental assessment of technological pathways. Ind Crops Prod 93:58–65. https://doi.org/10.1016/j.indcrop.2016.02.063

Abitbol T, Rivkin A, Cao Y et al (2016) Nanocellulose, a tiny fiber with huge applications. Curr Opin Biotechnol 39:76–88. https://doi.org/10.1016/j.copbio.2016.01.002

Klemm D, Cranston ED, Fischer D et al (2018) Nanocellulose as a natural source for groundbreaking applications in materials science: today’s state. Mater Today 21:720–748. https://doi.org/10.1016/j.mattod.2018.02.001

Wijaya CJ, Saputra SN, Soetaredjo FE et al (2017) Cellulose nanocrystals from passion fruit peels waste as antibiotic drug carrier. Carbohydr Polym 175:370–376. https://doi.org/10.1016/j.carbpol.2017.08.004

Jordan JH, Easson MW, Dien B et al (2019) Extraction and characterization of nanocellulose crystals from cotton gin motes and cotton gin waste. Cellulose 26:5959–5979. https://doi.org/10.1007/s10570-019-02533-7

Prado KS, Spinacé MAS (2019) Isolation and characterization of cellulose nanocrystals from pineapple crown waste and their potential uses. Int J Biol Macromol 122:410–416. https://doi.org/10.1016/j.ijbiomac.2018.10.187

Pereira PHF, Ornaghi Júnior HL, Coutinho LV et al (2020) Obtaining cellulose nanocrystals from pineapple crown fibers by free-chlorite hydrolysis with sulfuric acid: physical, chemical and structural characterization. Cellulose 27:5745–5756. https://doi.org/10.1007/s10570-020-03179-6

Dai H, Ou S, Huang Y, Huang H (2018) Utilization of pineapple peel for production of nanocellulose and film application. Cellulose 25:1743–1756. https://doi.org/10.1007/s10570-018-1671-0

Meng F, Wang G, Du X et al (2019) Extraction and characterization of cellulose nanofibers and nanocrystals from liquefied banana pseudo-stem residue. Compos Part B Eng 160:341–347. https://doi.org/10.1016/j.compositesb.2018.08.048

Arnata IW, Suprihatin S, Fahma F et al (2020) Cationic modification of nanocrystalline cellulose from sago fronds. Cellulose 27:3121–3141. https://doi.org/10.1007/s10570-019-02955-3

Al-Dulaimi AA, Wanrosli WD (2017) Isolation and characterization of nanocrystalline cellulose from totally chlorine free oil palm empty fruit bunch pulp. J Polym Environ 25:192–202. https://doi.org/10.1007/s10924-016-0798-z

Xiao Y, Liu Y, Wang X et al (2019) Cellulose nanocrystals prepared from wheat bran: characterization and cytotoxicity assessment. Int J Biol Macromol 140:225–233. https://doi.org/10.1016/j.ijbiomac.2019.08.160

Benito-González I, López-Rubio A, Gavara R, Martínez-Sanz M (2019) Cellulose nanocrystal-based films produced by more sustainable extraction protocols from Posidonia oceanica waste biomass. Cellulose 26:8007–8024. https://doi.org/10.1007/s10570-019-02641-4

Singh S, Gaikwad KK, Il PS, Lee YS (2017) Microwave-assisted step reduced extraction of seaweed (Gelidiella aceroso) cellulose nanocrystals. Int J Biol Macromol 99:506–510. https://doi.org/10.1016/j.ijbiomac.2017.03.004

Nepomuceno NC, Santos ASF, Oliveira JE et al (2017) Extraction and characterization of cellulose nanowhiskers from Mandacaru (Cereus jamacaru DC.) spines. Cellulose 24:119–129. https://doi.org/10.1007/s10570-016-1109-5

Zhang H, Chen Y, Wang S et al (2020) Extraction and comparison of cellulose nanocrystals from lemon (Citrus limon) seeds using sulfuric acid hydrolysis and oxidation methods. Carbohydr Polym 238:116180. https://doi.org/10.1016/j.carbpol.2020.116180

Fan Q, Jiang C, Wang W et al (2020) Eco-friendly extraction of cellulose nanocrystals from grape pomace and construction of self-healing nanocomposite hydrogels. Cellulose 27:2541–2553. https://doi.org/10.1007/s10570-020-02977-2

Song K, Ji Y, Wang L et al (2018) A green and environmental benign method to extract cellulose nanocrystal by ball mill assisted solid acid hydrolysis. J Clean Prod 196:1169–1175. https://doi.org/10.1016/j.jclepro.2018.06.128

Park NM, Choi S, Oh JE, Hwang DY (2019) Facile extraction of cellulose nanocrystals. Carbohydr Polym 223:115114. https://doi.org/10.1016/j.carbpol.2019.115114

Dai H, Wu J, Zhang H et al (2020) Recent advances on cellulose nanocrystals for Pickering emulsions: Development and challenge. Trends Food Sci Technol 102:16–29. https://doi.org/10.1016/j.tifs.2020.05.016

Orasugh JT, Sarkar G, Saha NR et al (2019) Effect of cellulose nanocrystals on the performance of drug loaded in situ gelling thermo-responsive ophthalmic formulations. Int J Biol Macromol 124:235–245. https://doi.org/10.1016/j.ijbiomac.2018.11.217

Wang Z, Yao Z, Zhou J et al (2019) Isolation and characterization of cellulose nanocrystals from pueraria root residue. Int J Biol Macromol 129:1081–1089. https://doi.org/10.1016/j.ijbiomac.2018.07.055

Kassab Z, Kassem I, Hannache H et al (2020) Tomato plant residue as new renewable source for cellulose production: extraction of cellulose nanocrystals with different surface functionalities. Cellulose 27:4287–4303. https://doi.org/10.1007/s10570-020-03097-7

Liu Y, Wang H, Yu G et al (2014) A novel approach for the preparation of nanocrystalline cellulose by using phosphotungstic acid. Carbohydr Polym 110:415–422. https://doi.org/10.1016/j.carbpol.2014.04.040

Yu H, Qin Z, Liang B et al (2013) Facile extraction of thermally stable cellulose nanocrystals with a high yield of 93% through hydrochloric acid hydrolysis under hydrothermal conditions. J Mater Chem A 1:3938–3944. https://doi.org/10.1039/c3ta01150j

Hastuti N, Kanomata K, Kitaoka T (2018) Hydrochloric acid hydrolysis of pulps from oil palm empty fruit bunches to produce cellulose nanocrystals. J Polym Environ 26:3698–3709. https://doi.org/10.1007/s10924-018-1248-x

Sadeghifar H, Filpponen I, Clarke SP et al (2011) Production of cellulose nanocrystals using hydrobromic acid and click reactions on their surface. J Mater Sci 46:7344–7355. https://doi.org/10.1007/s10853-011-5696-0

Couret L, Irle M, Belloncle C, Cathala B (2017) Extraction and characterization of cellulose nanocrystals from post-consumer wood fiberboard waste. Cellulose 24:2125–2137. https://doi.org/10.1007/s10570-017-1252-7

Esayas E, Agon EC, Assefa S (2018) Development of wall construction material stabilized with Enset vegetable fibers for rural housing units. Am J Civ Eng Archit 6:54–62. https://doi.org/10.12691/ajcea-6-2-2

Minten B, Tamru S, Engida E, Kuma T (2016) Feeding Africa’s cities: the case of the supply chain of Teff to Addis Ababa. Econ Dev Cult Change 64:265–297. https://doi.org/10.1086/683843

Borrell JS, Biswas MK, Goodwin M et al (2019) Enset in Ethiopia: a poorly characterized but resilient starch staple. Ann Bot 123:747–766. https://doi.org/10.1093/aob/mcy214

Gebre-Mariam T, Schmidt PC (1996) Isolation and physico-chemical properties of enset starch. Starch/Staerke 48:208–214. https://doi.org/10.1002/star.19960480603

Tena Gashaw E, Mekbib F, Ayana A (2018) Sugarcane landraces of Ethiopia: Germplasm collection and analysis of regional diversity and distribution. Adv Agric 2018:1–18. https://doi.org/10.1155/2018/7920724

Bickford R (2019) Ethiopia coffee annual coffee annual report—global agricultural information network

Wang Z, Dadi Bekele L, Qiu Y et al (2019) Preparation and characterization of coffee hull fiber for reinforcing application in thermoplastic composites. Bioengineered 10:397–408. https://doi.org/10.1080/21655979.2019.1661694

Gabriel T, Belete A, Syrowatka F et al (2020) Extraction and characterization of celluloses from various plant byproducts. Int J Biol Macromol 158:1248–1258. https://doi.org/10.1016/j.ijbiomac.2020.04.264

de Oliveira JP, Bruni GP, el Halal SLM et al (2019) Cellulose nanocrystals from rice and oat husks and their application in aerogels for food packaging. Int J Biol Macromol 124:175–184. https://doi.org/10.1016/j.ijbiomac.2018.11.205

Coelho CCS, Michelin M, Cerqueira MA et al (2018) Cellulose nanocrystals from grape pomace: production, properties and cytotoxicity assessment. Carbohydr Polym 192:327–336. https://doi.org/10.1016/j.carbpol.2018.03.023

Fortunati E, Puglia D, Monti M et al (2013) Extraction of cellulose nanocrystals from Phormium tenax fibres. J Polym Environ 21:319–328. https://doi.org/10.1007/s10924-012-0543-1

Yeasmin MS, Mondal MIH (2015) Synthesis of highly substituted carboxymethyl cellulose depending on cellulose particle size. Int J Biol Macromol 80:725–731. https://doi.org/10.1016/j.ijbiomac.2015.07.040

Lin L, Yan R, Liu Y, Jiang W (2010) In-depth investigation of enzymatic hydrolysis of biomass wastes based on three major components: cellulose, hemicellulose and lignin. Bioresour Technol 101:8217–8223. https://doi.org/10.1016/j.biortech.2010.05.084

Abdel-Halim ES (2014) Chemical modification of cellulose extracted from sugarcane bagasse: preparation of hydroxyethyl cellulose. Arab J Chem 7:362–371. https://doi.org/10.1016/j.arabjc.2013.05.006

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794. https://doi.org/10.1177/004051755902901003

Hermans H, Hermans JJ, Vermaas D, Weidinger A (1948) Deformation mechanism of cellulose gels. IV.* General relationship between orientation of the crystalline and that of the amorphous portion. J Polym Sci 3:1–9

Popescu M, Popescu C, Lisa G, Sakata Y (2011) Evaluation of morphological and chemical aspects of different wood species by spectroscopy and thermal methods. J Mol Struct 988:65–72. https://doi.org/10.1016/j.molstruc.2010.12.004

Aguayo MG, Pérez AF, Reyes G et al (2018) Isolation and characterization of cellulose nanocrystals from rejected fibers originated in the Kraft Pulping process. Polymers (Basel) 10:1145–1156. https://doi.org/10.3390/polym10101145

Kargarzadeh H, Ahmad I, Abdullah I et al (2012) Effects of hydrolysis conditions on the morphology, crystallinity, and thermal stability of cellulose nanocrystals extracted from kenaf bast fibers. Cellulose 19:855–866. https://doi.org/10.1007/s10570-012-9684-6

Gong J, Mo L, Li J (2018) A comparative study on the preparation and characterization of cellulose nanocrystals with various polymorphs. Carbohydr Polym 195:18–28. https://doi.org/10.1016/j.carbpol.2018.04.039

Hemmati F, Jafari SM, Kashaninejad M, Barani Motlagh M (2018) Synthesis and characterization of cellulose nanocrystals derived from walnut shell agricultural residues. Int J Biol Macromol 120:1216–1224. https://doi.org/10.1016/j.ijbiomac.2018.09.012

Shaheen TI, Emam HE (2018) Sono-chemical synthesis of cellulose nanocrystals from wood sawdust using acid hydrolysis. Int J Biol Macromol 107:1599–1606. https://doi.org/10.1016/j.ijbiomac.2017.10.028

Hafemann E, Battisti R, Marangoni C, Machado RAF (2019) Valorization of royal palm tree agroindustrial waste by isolating cellulose nanocrystals. Carbohydr Polym 218:188–198. https://doi.org/10.1016/j.carbpol.2019.04.086

Haafiz MKM, Hassan A, Zakaria Z, Inuwa IM (2014) Isolation and characterization of cellulose nanowhiskers from oil palm biomass microcrystalline cellulose. Carbohydr Polym 103:119–125. https://doi.org/10.1016/j.carbpol.2013.11.055

Korolovych VF, Cherpak V, Nepal D et al (2018) Cellulose nanocrystals with different morphologies and chiral properties. Polymer (Guildf) 145:334–347. https://doi.org/10.1016/j.polymer.2018.04.064

Di Giorgio L, Salgado PR, Dufresne A, Mauri AN (2020) Nanocelluloses from phormium (Phormium tenax) fibers. Cellulose 27:4975–4990. https://doi.org/10.1007/s10570-020-03120-x

Heggset EB, Chinga-Carrasco G, Syverud K (2017) Temperature stability of nanocellulose dispersions. Carbohydr Polym 157:114–121. https://doi.org/10.1016/j.carbpol.2016.09.077

Naduparambath S, Purushothaman E (2016) Sago seed shell: determination of the composition and isolation of microcrystalline cellulose (MCC). Cellulose 23:1803–1812. https://doi.org/10.1007/s10570-016-0904-3

García-García D, Balart R, Lopez-Martinez J et al (2018) Optimizing the yield and physico-chemical properties of pine cone cellulose nanocrystals by different hydrolysis time. Cellulose 25:2925–2938. https://doi.org/10.1007/s10570-018-1760-0

Rhim JW, Reddy JP, Luo X (2015) Isolation of cellulose nanocrystals from onion skin and their utilization for the preparation of agar-based bio-nanocomposites films. Cellulose 22:407–420. https://doi.org/10.1007/s10570-014-0517-7

Mueller S, Weder C, Foster EJ (2014) Isolation of cellulose nanocrystals from pseudostems of banana plants. RSC Adv 4:907–915. https://doi.org/10.1039/c3ra46390g

Dungani R, Owolabi AF, Saurabh CK et al (2017) Preparation and fundamental characterization of cellulose nanocrystal from oil palm fronds biomass. J Polym Environ 25:692–700. https://doi.org/10.1007/s10924-016-0854-8

Nang An V, Chi Nhan HT, Tap TD et al (2020) Extraction of high crystalline nanocellulose from biorenewable sources of Vietnamese agricultural wastes. J Polym Environ 28:1465–1474. https://doi.org/10.1007/s10924-020-01695-x

César NR, Pereira-da-Silva MA, Botaro VR, de Menezes AJ (2015) Cellulose nanocrystals from natural fiber of the macrophyte Typha domingensis: extraction and characterization. Cellulose 22:449–460. https://doi.org/10.1007/s10570-014-0533-7

Ferreira FV, Mariano M, Rabelo SC et al (2018) Isolation and surface modification of cellulose nanocrystals from sugarcane bagasse waste: from a micro- to a nano-scale view. Appl Surf Sci 436:1113–1122. https://doi.org/10.1016/j.apsusc.2017.12.137

De OFB, Bras J, Pimenta MTB et al (2016) Production of cellulose nanocrystals from sugarcane bagasse fibers and pith. Ind Crops Prod 93:48–57. https://doi.org/10.1016/j.indcrop.2016.04.064

Newman RH (1999) Estimation of the lateral dimensions of cellulose crystallites using 13C NMR signal strengths. Solid State Nucl Magn Reson 15:21–29. https://doi.org/10.1016/S0926-2040(99)00043-0

Wada M, Okano T (2001) Localization of Iα and Iβ phases in algal cellulose revealed by acid treatments. Cellulose 8:183–188. https://doi.org/10.1023/A:1013196220602

Kim UJ, Eom SH, Wada M (2010) Thermal decomposition of native cellulose: Influence on crystallite size. Polym Degrad Stab 95:778–781. https://doi.org/10.1016/j.polymdegradstab.2010.02.009

French AD (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21:885–896. https://doi.org/10.1007/s10570-013-0030-4

Poletto M, Zattera AJ, Forte MMC, Santana RMC (2012) Thermal decomposition of wood: influence of wood components and cellulose crystallite size. Bioresour Technol 109:148–153. https://doi.org/10.1016/j.biortech.2011.11.122

He Q, Wang Q, Zhou H et al (2018) Highly crystalline cellulose from brown seaweed Saccharina japonica: isolation, characterization and microcrystallization. Cellulose 25:5523–5533. https://doi.org/10.1007/s10570-018-1966-1

Yang H, Yan R, Chen H et al (2007) Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 86:1781–1788. https://doi.org/10.1016/j.fuel.2006.12.013

Mohamad Haafiz MK, Eichhorn SJ, Hassan A, Jawaid M (2013) Isolation and characterization of microcrystalline cellulose from oil palm biomass residue. Carbohydr Polym 93:628–634. https://doi.org/10.1016/j.carbpol.2013.01.035

Sukyai P, Anongjanya P, Bunyahwuthakul N et al (2018) Effect of cellulose nanocrystals from sugarcane bagasse on whey protein isolate-based films. Food Res Int 107:528–535. https://doi.org/10.1016/j.foodres.2018.02.052

Mandal A, Chakrabarty D (2011) Isolation of nanocellulose from waste sugarcane bagasse (SCB) and its characterization. Carbohydr Polym 86:1291–1299. https://doi.org/10.1016/j.carbpol.2011.06.030

Saha S, Ghosh R (2019) Cellulose nanocrystals from lignocellulosic agro-waste: a comparative study on conventional and ultrasonic assisted preparation methods. Mater Today Proc 11:628–636. https://doi.org/10.1016/j.matpr.2019.03.020

Thomas D, Latha MS, Thomas KK (2018) Synthesis and in vitro evaluation of alginate-cellulose nanocrystal hybrid nanoparticles for the controlled oral delivery of rifampicin. J Drug Deliv Sci Technol 46:392–399. https://doi.org/10.1016/j.jddst.2018.06.004

de Benini KCCC, Voorwald HJC, Cioffi MOH et al (2018) Preparation of nanocellulose from Imperata brasiliensis grass using Taguchi method. Carbohydr Polym 192:337–346. https://doi.org/10.1016/j.carbpol.2018.03.055

Stinson-Bagby KL, Roberts R, Foster EJ (2018) Effective cellulose nanocrystal imaging using transmission electron microscopy. Carbohydr Polym 186:429–438. https://doi.org/10.1016/j.carbpol.2018.01.054

Xing L, Gu J, Zhang W et al (2018) Cellulose I and II nanocrystals produced by sulfuric acid hydrolysis of Tetra pak cellulose I. Carbohydr Polym 192:184–192. https://doi.org/10.1016/j.carbpol.2018.03.042

Silvério HA, Flauzino Neto WP, Dantas NO, Pasquini D (2013) Extraction and characterization of cellulose nanocrystals from corncob for application as reinforcing agent in nanocomposites. Ind Crops Prod 44:427–436. https://doi.org/10.1016/j.indcrop.2012.10.014

Lam NT, Chollakup R, Smitthipong W et al (2017) Characterization of cellulose nanocrystals extracted from sugarcane bagasse for potential biomedical materials. Sugar Tech 19:539–552. https://doi.org/10.1007/s12355-016-0507-1

Bano S, Negi YS (2017) Studies on cellulose nanocrystals isolated from groundnut shells. Carbohydr Polym 157:1041–1049. https://doi.org/10.1016/j.carbpol.2016.10.069

Wijaya CJ, Ismadji S, Aparamarta HW, Gunawan S (2019) Optimization of cellulose nanocrystals from bamboo shoots using Response Surface Methodology. Heliyon 5:e02807. https://doi.org/10.1016/j.heliyon.2019.e02807

Acknowledgements

The authors would like to acknowledge Addis Ababa University, Ethiopia for sponsoring the PhD study of TG, and Martin Luther University, Germany for providing access to laboratory space and facilities such as TEM and DLS. This research was partly supported by the Ministry of Innovation and Technology, Ethiopia, and Tri-Sustain (Economic, Ecological and Therapeutic Sustainability) Project in the development of phytopharmaceuticals for Sub-Saharan Africa, funded by the German Ministry of Research and Education (BmBF) (Grant No. 01DG17008B) and German Academic Exchange Service (DAAD) (Grant No. 57369155), Germany.

Author information

Authors and Affiliations

Contributions

Conceptualization, Methodology, Investigation, Visualization, original draft Writing, Software: TG. Writing—review & editing, Formal analysis: AB. Software, Methodology, Writing—review & editing: GH. Funding acquisition, Project administration, Writing—review & editing: RN. Conceptualization, Investigation, Supervision, Visualization, Writing—review & editing, Funding acquisition: TG-M.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Gabriel, T., Belete, A., Hause, G. et al. Isolation and Characterization of Cellulose Nanocrystals from Different Lignocellulosic Residues: A Comparative Study. J Polym Environ 29, 2964–2977 (2021). https://doi.org/10.1007/s10924-021-02089-3

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-021-02089-3