Abstract

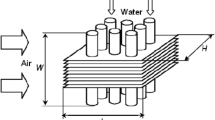

This research examines the effects of a tube fitted with twisted tape on the optimal design of a fin-and-tube heat exchanger (FTHE). The twisted tape on the tube side results in a trade-off between the heat transfer and pressure drop, so both the effectiveness (which is related to the rate of heat transfer) and the total annual cost (which is related to the heat transfer area and pressure drop) were optimized simultaneously. All the physical parameters of the FTHE were considered as design parameters, and the optimization was performed using a genetic algorithm for different mass flow rates of the tube side. All the optimum results in the case with the twisted tape tube (TTT) were compared with the case of a plain tube (PT). The optimum results show that the Pareto front for the case of the TTT was completely dominant over the PT for lower mass flow rate (0.25 kg s−1). Both the effectiveness and annual cost were enhanced in the TTT compared with the PT at the lower mass flow rate. On the other hand, for higher mass flow rates, there was a marginal point for effectiveness at which the Pareto front of TTT is dominant over that of the PT. For example, the TTT was optimal for effectiveness higher than 0.73, while the PT was optimal for effectiveness lower than 0.73 at a mass flow rate of 0.5 kg s−1. For the low mass flow rate, the TTT is recommended for a wide range of effectiveness, while in the case of high mass flow rate, the TTT is recommended for just high effectiveness.

Similar content being viewed by others

Abbreviations

- A flow :

-

Minimum free-flow area (m2)

- A :

-

Heat transfer surface area (m2)

- C min :

-

Minimum of Ch and Cc (W K−1)

- C max :

-

Maximum of Ch and Cc (W K−1)

- C*:

-

Heat capacity rate ratio (Cmin/Cmax)

- C in :

-

Investment cost ($ year−1)

- C np :

-

Cost of nanoparticles

- C op :

-

Operational cost ($ year−1)

- C p :

-

Heat capacity (J K−1)

- d c :

-

Fin collar outside diameter (m)

- d i :

-

Tube inside diameter (m)

- d o :

-

Tube outside diameter (m)

- D h :

-

Hydraulic diameter (m)

- f :

-

Friction factor (−)

- G :

-

Mass flux (kg m−2 s−1)

- h :

-

Convection heat transfer coefficient (W m−2 K−1)

- H :

-

Twisted tape pitch (m)

- I :

-

Modified Bessel function (−)

- i :

-

Interest rate (−)

- j :

-

Colburn factor (−)

- k el :

-

Unit price of electricity ($ MWh−1)

- L 1 :

-

Cold stream flow length (m)

- L 2 :

-

Hot stream flow length (m)

- L 3 :

-

No-flow length (m)

- NTU:

-

Number of transfer units (−)

- Nu :

-

Nusselt number (−)

- n :

-

System lifetime (year)

- N l :

-

Number of plate in L1 direction (−)

- N r :

-

Number of tube row (−)

- N t :

-

Total number of tubes (−)

- p f :

-

Fin pitch (m)

- Pr :

-

Prandtl number (−)

- PT:

-

Heat exchanger with plain tube (−)

- Q :

-

Rate of heat transfer (kW)

- Re :

-

Reynolds number (−)

- St :

-

Stanton number (−)

- TTT:

-

Heat exchanger with twisted tape tube (−)

- U :

-

Overall heat transfer coefficient (W m−2 K−1)

- V t :

-

Volumetric flow rate (m3 s−1)

- X l :

-

Longitudinal pitch (m)

- X t :

-

Transversal pitch (m)

- ΔP :

-

Pressure drop (kPa)

- ɛ :

-

Thermal effectiveness (−)

- τ :

-

Hours of operation per year (h)

- η s :

-

Overall efficiency of fin array (−)

- η f :

-

Single fin efficiency (−)

- η is :

-

Efficiency of pump/compressor (−)

- μ :

-

Viscosity (Pa s)

- ρ :

-

Density (kg m−3)

- σ :

-

Ratio between Aflow and Afront (Aflow/Afront)

- c:

-

Cold

- h:

-

Hot

- I:

-

Inside

- max:

-

Maximum

- o:

-

Outside

- tot:

-

Total

References

Bahiraei M, Jamshidmofid M, Heshmatian S. Entropy generation in a heat exchanger working with a biological nanofluid considering heterogeneous particle distribution. Adv Powder Technol. 2017;28(9):2380–92.

Bahiraei M, Rahmani R, Yaghoobi A, Khodabandeh E, Mashayekhi R, Amani M. Recent research contributions concerning use of nanofluids in heat exchangers: a critical review. Appl Therm Eng. 2018;133:137–59.

Bahiraei M, Jamshidmofid M, Amani M, Barzegarian R. Investigating exergy destruction and entropy generation for flow of a new nanofluid containing graphene–silver nanocomposite in a micro heat exchanger considering viscous dissipation. Powder Technol. 2018;336:298–310.

Zhang ZX, Wang YG, Zhao QX. Numerical study on performance optimization H-type finned tubes. J Chin Soc Power Eng. 2010;30:941–6.

Wang H, Liu YW, Yang P, Wu RJ, He YL. Parametric study and optimization of H-type finned tube heat exchangers using Taguchi method. Appl Therm Eng. 2016;103:128–38.

Liu YZ, Yuan YC, Xu SY, Wu WB. Experimental study on the characteristics of heat transfer and flow resistance for H-type finned tube banks. J Univ Shanghai Sci Technol. 2004;26(5):457–60.

Zhao XB, Tang GH, Ma XW, Jin Y, Tao WQ. Numerical investigation of heat transfer and erosion characteristics for H-type finned oval tube with longitudinal vortex. Appl Energy. 2014;127:93–104.

Wang ZJ, Zeng ZX, Xu YH. Study on heat transfer and resistance characteristics of H-type finned tube. Adv Mater Res. 2013;805–806:1817–22.

Jin Y, Tang GH, He YL, Tao WQ. Parametric study and field synergy principle analysis of H-type finned tube bank with 10 rows. Int J Heat Mass Transf. 2013;60:241–51.

Nyamsi SN, Yang F, Zhang Z. An optimization study on the finned tube heat exchanger used in hydride hydrogen storage system—analytical method and numerical simulation. Int J Hydrog Energy. 2012;37:16078–92.

Ameel B, Degroote J, T’Joen C, Huisseune H, Schampheleire SD, Vierendeels J, Paepe MD. Optimization of X-shaped louvered fin and tube heat exchangers while maintaining the physical meaning of the performance evaluation criterion. Appl Therm Eng. 2013;58:136–45.

Sajedi R, Taghilou M, Jafari M. Experimental and numerical study on the optimal fin numbering in an external extended finned tube heat exchanger. Appl Therm Eng. 2015;83:139–46.

Pongsoi P, Pikulkajorn S, Wongwises S. Effect of fin pitches on the optimum heat transfer performance of crimped spiral fin-and-tube heat exchangers. Int J Heat Mass Transf. 2012;55:6555–66.

Kundu B, Das PK. Performance and optimum dimensions of flat fins for tube-and-fin heat exchangers: a generalized analysis. Int J Heat Fluid Flow. 2009;30:658–68.

Tang LH, Zeng M, Wang QW. Experimental and numerical investigation on air-side performance of fin-and-tube heat exchangers with various fin patterns. Exp Therm Fluid Sci. 2009;33:818–27.

Yang DK, Lee KS, Song S. Fin spacing optimization of a fin-tube heat exchanger under frosting conditions. Int J Heat Mass Transf. 2006;49:2619–25.

Ameel B, Degroote J, T’Joen C, Huisseune H, Schampheleire SD, Vierendeels J, Paepe MD. Accounting for the effect of the heat exchanger length in the performance evaluation of compact fin and tube heat exchangers. Appl Therm Eng. 2014;65:544–53.

Kang YT, Stout R, Christensen RN. The effects of inclination angle on flooding in a helically fluted tube a twisted insert. Int J Multiph Flow. 1997;23:1111–29.

Agarwalt SK, Rao MR. Heat transfer augmentation for the flow of a viscous liquid in circular tubes using twisted tape inserts. Int J Heat Mass Transf. 1996;39:3547–57.

Kumara A, Prasad BN. Investigation of twisted tape inserted solar water heaters heat transfer, friction factor and thermal performance results. Renew Energy. 2000;19:379–98.

Al-Fahed S, Chamra LM, Chakroun W. Pressure drop and heat transfer comparison for both microfin tube and twisted-tape inserts in laminar flow. Exp Therm Fluid Sci. 1999;18:323–33.

Naphon P. Heat transfer and pressure drop in the horizontal double pipes with and without twisted tape insert. Int Commun Heat Mass Transf. 2006;33:166–75.

Hajabdollahi H, Hajabdollahi Z. Investigating the effect of nanoparticle on thermo-economic optimization of fin and tube heat exchanger. Proc Inst Mech Eng Part E. 2016;23:0954408916656677.

Pusey A, Kim D, Park H-S, Kwon T-S, Kim H. Visualization method for cross-sectional two-phase flow structure during the condensation of steam in a tube. J Vis. 2017;20(3):591–605. https://doi.org/10.1007/s12650-016-0408-0.

Jeong T-S, Yu J-H, Lim D-I, Kim H-B. Quantitative flow visualization in the distributor of a plate-fin heat exchanger. J. Vis. 2018;21(6):1031–41. https://doi.org/10.1007/s12650-018-0505-3.

Damavandi MD, Forouzanmehr M, Safikhani H. Modeling and Pareto based multi-objective optimization of wavy fin-and-elliptical tube heat exchangers using CFD and NSGA-II algorithm. Appl Soft Comput. 2012;12:3648–55.

Hatami M, Ganji DD, Gorji-Bandpy M. Experimental and numerical analysis of the optimized finned-tube heat exchanger for OM314 diesel exhaust exergy recovery. Energy Convers Manag. 2015;97:26–41.

Dezan D, Salviano LO, Yanagihara JI. Heat transfer enhancement and optimization of flat-tube multilouvered fin compact heat exchangers with delta-winglet vortex generators. Appl Therm Eng. 2016;101:576–91.

Bilir L, İlken Z, Erek A. Numerical optimization of a fin-tube gas to liquid heat exchanger. Int J Therm Sci. 2012;52:59–72.

Hajabdollahi H, Ahmadi P, Dincer I. Multi-objective optimization of plain fin-and-tube heat exchanger using evolutionary algorithm. J Thermophys Heat Transf. 2011;25(3):424–31.

Bahiraei M, Mazaheri N, Rizehvandi A. Application of a hybrid nanofluid containing graphene nanoplatelet–platinum composite powder in a triple-tube heat exchanger equipped with inserted ribs. Appl Therm Eng. 2019;149:588–601.

Bahiraei M, Salmi HK, Safaei MR. Effect of employing a new biological nanofluid containing functionalized graphene nanoplatelets on thermal and hydraulic characteristics of a spiral heat exchanger. Energy Convers Manag. 2019;180:72–82.

Franco A, Giannini N. Optimum thermal design of modular compact heat exchangers structure for heat recovery steam generators. Appl Therm Eng. 2005;25:1293–313.

Shah RK, Sekulic P. Fundamental of heat exchanger design. New York: Wiley; 2003.

Wang CC, Chi KU, Chang CJ. Heat transfer and friction characteristics of plain fin-and-tube heat exchanger, part 2: correlation. Int J Heat Mass Transf. 2000;43:2693–700.

Naphon P. Heat transfer and pressure drop in the horizontal double pipes with and without twisted tape insert. Int Commun Heat Mass Transf. 2006;33(2):166–75.

Deb K. Multi-objective optimization using evolutionary algorithms. Chichester: Wiley; 2001.

Yu PL. Multiple-criteria decision making, concepts, techniques, and extensions. New York: Plenum Press; 1985.

Acknowledgements

This research was supported by the International Research and Development Program of the National Research Foundation of Korea (NRF), which is funded by the Ministry of Science and ICT of Korea (NRF-2017K1A3A1A30084513). Partial support was also obtained from the National Research Foundation of Korea (NRF) grant, which is funded by the Korean government (MSIT) (Nos. 2011-0030013, 2018R1A2B2007117).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hajabdollahi, Z., Hajabdollahi, H. & Kim, K.C. Heat transfer enhancement and optimization of a tube fitted with twisted tape in a fin-and-tube heat exchanger. J Therm Anal Calorim 140, 1015–1027 (2020). https://doi.org/10.1007/s10973-019-08668-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08668-w