Abstract

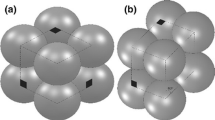

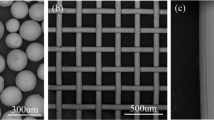

A composite porous wick with spherical–dendritic powders is proposed, in which the dendritic powders fill the gap between the spherical powders. A unique biporous structure can be realized in this composite porous wick, including small pores between dendritic powders, small pores between spherical and dendritic powders and large pores between spherical powders. Two metal powders (copper and nickel) with two structures (spherical and dendritic) are chosen as the prepared materials, and four composite porous wicks are fabricated. The hydraulic and thermal characteristics of the composite porous wick are studied experimentally. Two capillary pumping stages have been observed in the composite porous wick. And the combination of powders with different metal materials or different structures reduces the effective thermal conductivity of porous wick. Two evaporation heat transfer modes have been observed in evaporation heat transfer experiment, including the evaporation in the vapor grooves and the meniscus evaporation in porous wick. The composite porous wick with dendritic copper powders shows good evaporation heat transfer performance, in which the effective thermal conductivity is not the lowest. Both higher local thermal conductivity and larger equivalent pore diameter exist in this composite porous wick, which is advantage to the meniscus evaporation.

Similar content being viewed by others

References

Maydanik YF. Loop heat pipes. Appl Therm Eng. 2005;25:635–57.

Maydanik YF, Chernysheva MA, Pastukhov VG. Review: loop heat pipes with flat evaporators. Appl Therm Eng. 2014;67:294–307.

Zhou G, Li J. Two-phase flow characteristics of a high performance loop heat pipe with flat evaporator under gravity. Int J Heat Mass Transf. 2018;117:1063–74.

Li H, Liu Z, Chen B, Liu W, Li C, Yang J. Development of biporous wicks for flat-plate loop heat pipe. Exp Thermal Fluid Sci. 2012;37:91–7.

Singh R, Akbarzadeh A, Mochizuki M. Effect of wick characteristics on the thermal performance of the miniature loop heat pipe. J Heat Transf. 2009;131:082601.

Wu SC, Hsieh BH, Wang D, Chen YM. Manufacture of a biporous nickel wick and its effect on LHP heat transfer performance enhancement. Heat Mass Transf. 2015;51:1549–58.

Chen BB, Liu W, Liu ZC, Li H, Yang JG. Experimental investigation of loop heat pipe with flat evaporator using biporous wick. Appl Therm Eng. 2012;42:34–40.

Liu Z, Li H, Chen B, Yang J, Liu W. Operational characteristics of flat type loop heat pipe with biporous wick. Int J Therm Sci. 2012;58:180–5.

Chen BB, Liu ZC, Liu W, Yang JG, Li H, Wang DD. Operational characteristics of two biporous wicks used in loop heat pipe with flat evaporator. Int J Heat Mass Transf. 2012;55:2204–7.

Wang D, Liu Z, Shen J, Jiang C, Chen B, Yang J, Tu Z, Liu W. Experimental study of the loop heat pipe with a flat disk-shaped evaporator. Exp Thermal Fluid Sci. 2014;57:157–64.

Wang D, Liu Z, Song H, Yang J, Wei L. Operational characteristics of a loop heat pipe with a flat evaporator and two primary biporous wicks. Int J Heat Mass Transf. 2015;89:33–41.

Liu Z, Wang D, Jiang C, Yang J, Liu W. Experimental study on loop heat pipe with two-wick flat evaporator. Int J Therm Sci. 2015;94:9–17.

Byon C, Kim SJ. Capillary performance of bi-porous sintered metal wicks. Int J Heat Mass Transf. 2012;55:4096–103.

Wang J, Catton I. Evaporation heat transfer in thin biporous media. Heat Mass Transf. 2001;37:275–81.

Mottet L, Prat M. Numerical simulation of heat and mass transfer in bidispersed capillary structures: application to the evaporator of a loop heat pipe. Appl Therm Eng. 2016;102:770–84.

Lin FC, Liu BH, Huang CT, Chen YM. Evaporative heat transfer model of a loop heat pipe with bidisperse wick structure. Int J Heat Mass Transf. 2011;54:4621–9.

Semenic T, Lin YY, Catton I, Sarraf DB. Use of biporous wicks to remove high heat fluxes. Appl Therm Eng. 2008;28:278–83.

Yeh CC, Chen CN, Chen YM. Heat transfer analysis of a loop heat pipe with biporous wicks. Int J Heat Mass Transf. 2009;52:4426–34.

Lin FC, Liu BH, Juan CC, Chen Y-M. Effect of pore size distribution in bidisperse wick on heat transfer in a loop heat pipe. Heat Mass Transf. 2011;47:933–40.

Xu J, Ji X, Yang W, Zhao Z. Modulated porous wick evaporator for loop heat pipes: experiment. Int J Heat Mass Transf. 2014;72:163–76.

Ji X, Wang Y, Xu J, Huang Y. Experimental study of heat transfer and start-up of loop heat pipe with multiscale porous wicks. Appl Therm Eng. 2017;117:782–98.

Nishikawara M, Nagano H. Parametric experiments on a miniature loop heat pipe with PTFE wicks. Int J Therm Sci. 2014;85:29–39.

Boo JH, Chung WB. Experimental study on the thermal performance of a small-scale loop heat pipe with polypropylene wick. J Mech Sci Technol. 2005;19:1052–61.

Santos PHD, Bazzo E, Becker S, Kulenovic R, Mertz R. Development of LHPs with ceramic wick. Appl Therm Eng. 2010;30:1784–9.

Xu J, Zou Y, Fan M, Cheng L. Effect of pore parameters on thermal conductivity of sintered LHP wicks. Int J Heat Mass Transf. 2012;55:2702–6.

Semenic T, Lin Y-Y, Catton I. Thermophysical properties of biporous heat pipe evaporators. J Heat Transfer. 2008;130:022602.

Xin G, Cui K, Zou Y, Cheng L. Reduction of effective thermal conductivity for sintered LHP wicks. Int J Heat Mass Transf. 2010;53:2932–4.

Ling W, Zhou W, Liu R, Qiu Q, Ke Y. Operational characteristics of loop heat pipes with porous copper fiber sintered sheet as wick. Appl Therm Eng. 2017;122:398–408.

Tang Y, Tang H, Li J, Zhang S, Zhuang B, Sun Y. Experimental investigation of capillary force in a novel sintered copper mesh wick for ultra-thin heat pipes. Appl Therm Eng. 2017;115:1020–30.

Esarte J, Blanco JM, Bernardini A, San-José JT. Optimizing the design of a two-phase cooling system loop heat pipe: wick manufacturing with the 3D selective laser melting printing technique and prototype testing. Appl Therm Eng. 2017;111:407–19.

Jafari D, Wits WW, Geurts BJ. Metal 3D-printed wick structures for heat pipe application: capillary performance analysis. Appl Therm Eng. 2018;143:403–14.

Delker T, Pengra DB, Wong P. Interface pinning and the dynamics of capillary rise in porous media. Phys Rev Lett. 1996;76(16):2902–5.

Li J, Zou Y, Cheng L. Experimental study on capillary pumping performance of porous wicks for loop heat pipe. Exp Thermal Fluid Sci. 2010;34(8):1403–8.

Li J, Zou Y, Cheng L, Singh R, Akbarzadeh A. Effect of fabricating parameters on properties of sintered porous wicks for loop heat pipe. Powder Technol. 2010;204:241–8.

Qu Y, Zhou K, Zhang KF, Tian Y. Effects of multiple sintering parameters on the thermal performance of bi-porous nickel wicks in Loop Heat Pipes. Int J Heat Mass Transf. 2016;99:638–46.

Wang D, Wang J, Bao X, Chen G, Chu H. Evaporation heat transfer characteristics of composite porous wick with spherical–dendritic powders. Appl Therm Eng. 2019;152:825–34.

Acknowledgements

The authors greatly appreciate the financial support provided by the National Natural Science Foundation of China (No. 51706001) and the Provincial Natural Science Foundation of Anhui (KJ2016A095).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, D., Wang, J., Bao, X. et al. Experimental study on hydraulic and thermal characteristics of composite porous wick with spherical–dendritic powders. J Therm Anal Calorim 141, 107–117 (2020). https://doi.org/10.1007/s10973-019-08920-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08920-3