Abstract

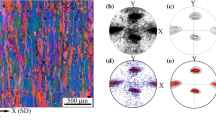

A new method for analyzing microstructure is proposed to evaluate the long-range dependence of texture. The proposed method calculates the average disorientation as a function of distance between data points as measured by electron backscatter diffraction patterns. This method gives a measure of clustering of texture and is used to evaluate accurately the effective grain size. This procedure in conjunction with Information theory is used to estimate a representative scan size for various materials. Analyses show that the optimal scan size depends on grain morphology and crystallographic texture. The results also indicate that on an average the optimal scan size needs to be 10 times the effective grain size.

Similar content being viewed by others

Notes

Defined here as the maximum intensity in pole figures.

The details in this are fascinating but will not be discussed here to avoid diversion from the main thrust of the current study.

Grain size reported in Table I is grain radius.

References

J.A. Venables and C.J. Harland: Philos. Mag., 1973, vol. 27, no. 5, pp. 1193–1200.

B. Adams, S. Wright, and K. Kunze: Metall. Trans. A, 1993, vol. 24A, pp. 819–31

K. Kunze, S.I. Wright, B.L. Adams, and D.J. Dingley: Texture Microstruct., 1993, vol. 20, nos. 1–4, pp. 41–54.

D.R. Steinmetz and S. Zaefferer: Mater. Sci. Technol., 2010, vol. 26, no. 6, pp. 640–45.

A. Brahme, J. Fridy, H. Weiland, and A.D. Rollett: Model. Simul. Mater. Sci. Eng., 2009, vol. 17 (1), p. 015005.

O.M. Ivasishin, S.V. Shevchenko, N.L. Vasiliev, and S.L. Semiatin: Mater. Sci. Eng. A, 2006, vol. 433, nos. 1–2, pp. 216–32.

D. Raabe and L. Hantcherli: Comput. Mater. Sci., 2005, vol. 34, no. 4, pp. 299–313.

A. Bhattacharyya, E. El-Danaf, S.R. Kalidindi, and R.D. Doherty: Int. J. Plast., 2001, vol. 17, no. 6, pp. 861–83.

D. Raabe, M. Sachtleber, Z. Zhao, F. Roters, and S. Zaefferer: Acta Mater., 2001, vol. 49, no. 17, pp. 3433–41.

A. Musienko, A. Tatschl, K. Schmidegg, O. Kolednik, R. Pippan, G. Cailletaud: Acta Mater., 2007, vol. 55, no. 12, pp. 4121–36.

K. Inal, M.H. Simha, and R.K. Mishra: J. Eng. Mater. Technol., 2008, vol. 130, pp. 021003-1–021003-8.

R. Lebensohn, R. Brenner, O. Castelnau, and A. Rollett: Acta Mater., 2008, vol. 56, no. 15, pp. 3914–26.

V.V. Fedorov: Theory of Optimal Experiments, Academic Press, New York, 1972.

C.A. Schuh, M. Kumar, and W.E. King: Acta Mater., 2003, vol. 51, no. 3, pp. 687–700.

F.J. Humphreys: J. Microsc., 1999, vol. 195, no. 3, pp. 170–85.

S.I. Wright, M.M. Nowell, and J.F. Bingert: Metall. Mater. Trans. A, 2007, vol. 38A, pp. 1845–55.

T. Baudin and R. Penelle: Metall. Trans. A, 1993, vol. 24, pp. 2299–2311.

K. Davut and S. Zaefferer: Metall. Mater. Trans. A, 2010, vol. 41A, pp. 2187–96.

H.J. Bunge: Texture Analysis in Materials Science, Butterworths, London, 1982.

B. Beausir, C. Fressengeas, N.P. Gurao, L.S. Toth, and S. Suwas: Acta Mater., 2009, vol. 57, no. 18, pp. 5382–95.

B. Adams, P. Morris, T. Wang, K. Willden, and S. Wright: Acta Metall., 1987, vol. 35, no. 12, pp. 2935–46.

N.R. Barton and P.R. Dawson: Model. Simul. Mater. Sci. Eng., 2001, vol. 9, no. 5, p. 433.

A. Vorhauer, T. Hebesberger, and R. Pippan: Acta Mater., 2003, vol. 51, no. 3, pp. 677–86.

R.M. Gray: Entropy and Information Theory, Springer, New York, 2009.

S. Kullback and R.A. Leibler: Ann. Math. Stat., 1951, vol. 22, no. 1, pp. 79–86.

J.H. Chang and W.S. Lee: J. Inf. Sci., 2005, vol. 31, pp. 420–32.

Acknowledgments

This work was supported by the Natural Sciences and Engineering Research Council of Canada (NSERC) and General Motors of Canada. The authors also gratefully acknowledge the High Performance Computing Center at the University of Sherbrooke (RQCHP).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted February 23, 2012.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Supplementary material 1 (MPEG 488 kb)

Rights and permissions

About this article

Cite this article

Brahme, A., Staraselski, Y., Inal, K. et al. Determination of the Minimum Scan Size to Obtain Representative Textures by Electron Backscatter Diffraction. Metall Mater Trans A 43, 5298–5307 (2012). https://doi.org/10.1007/s11661-012-1364-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-012-1364-5